Preparation method for porous carbon material and porous carbon material

A technology of porous carbon materials and foaming materials, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of high cost and difficult industrialization, and achieve the effects of low cost, stable structure and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

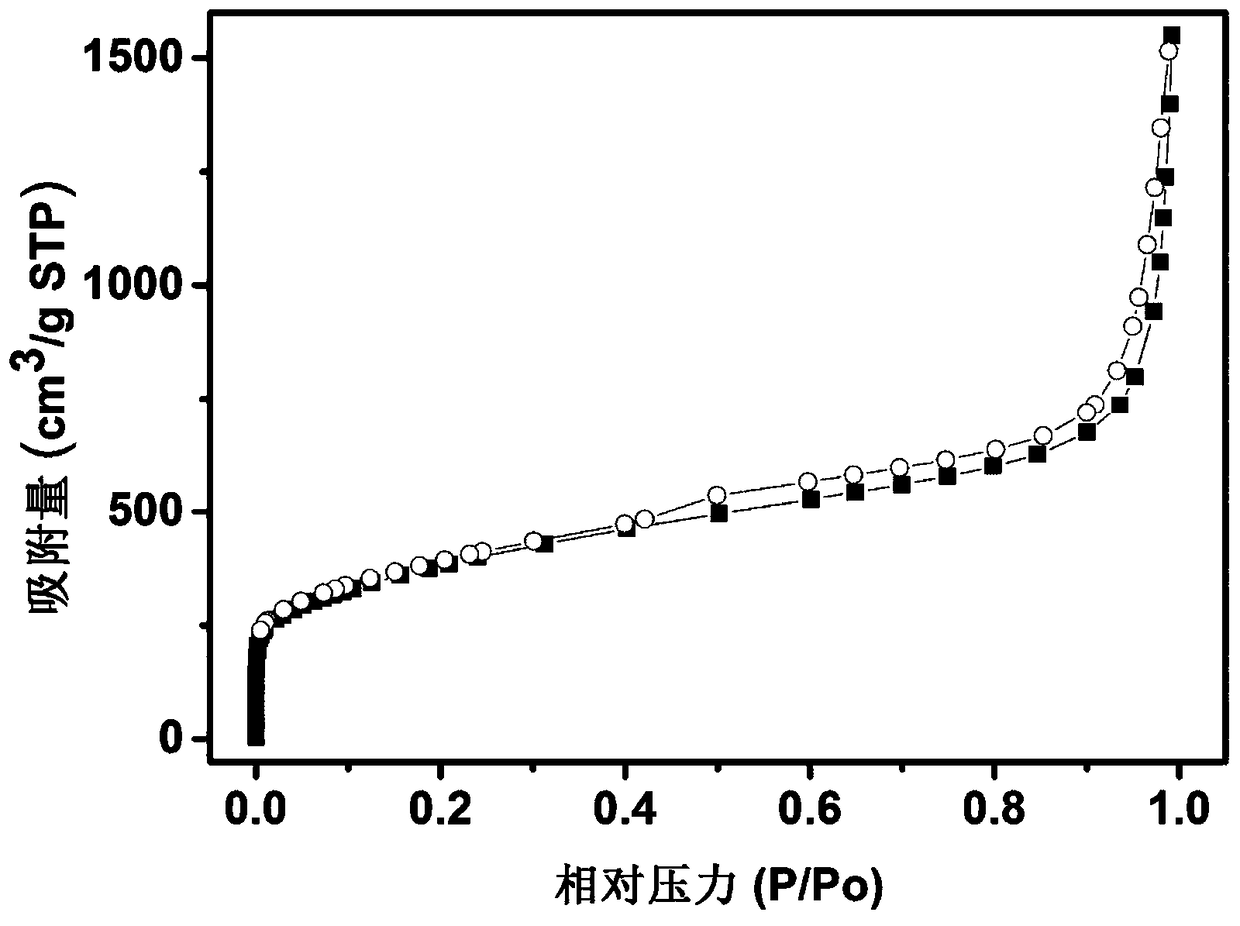

[0028] A preparation method of a porous carbon material, using expanded polyethylene as a carbon source, comprising the steps of:

[0029] First dry the polyethylene material at 80°C for 4 hours, then mix the dried polyethylene (95wt%) with 4,4-disulfonylhydrazide diphenyl ether (OBSH) foaming agent (5wt%) evenly The mixed material is obtained, and the mixed material is molded in a flat vulcanizing machine at a processing temperature of 160° C. and a holding time of 3 minutes, and the obtained product is dried at 60° C. for 2 hours. Then the dried product is transferred to a porcelain boat, and then transferred to a tubular carbonization furnace. Under a flowing nitrogen atmosphere (nitrogen flow rate is 120cc / min), the temperature is raised to 400°C at a rate of 3°C / min and then kept for 3 Carry out carbonization treatment within 1 hour, after the temperature drops to room temperature, take out the sample to obtain the porous carbon material.

Embodiment 2

[0031] A kind of preparation method of porous carbon material, take expanded polypropylene as carbon source, comprises the steps:

[0032] First dry the polypropylene material at 80°C for 4 hours, then evenly mix the dried polypropylene (93wt%) and ABN foaming agent (7wt%) to obtain a mixture, and place the mixture on a flat vulcanizer Molding process is carried out in the middle, the processing temperature is 230 ℃, the holding time is 5 minutes, and the obtained product is dried at 60 ℃ for 2 hours. Then transfer the dried product to a porcelain boat, and then transfer it to a tubular carbonization furnace. Under a flowing nitrogen atmosphere (120cc / min), the temperature is raised to 500°C at a rate of 3°C / min and then kept for 4 hours for carbonization. After the temperature drops to room temperature, the sample is taken out to obtain a porous carbon material.

Embodiment 3

[0034] A kind of preparation method of porous carbon material, take expanded polyvinyl chloride as carbon source, comprises the steps:

[0035] First dry the polyvinyl chloride material at 80°C for 4 hours, then mix the dried polyvinyl chloride (94wt%), silane coupling agent Z6043 (3wt%) and DIPA foaming agent (3wt%) evenly to obtain Mixed material, the mixed material is molded in a flat vulcanizing machine, the processing temperature is 190°C, the holding time is 5 minutes, and the obtained product is dried at 60°C for 2 hours. Then transfer the dried product to a porcelain boat, and then transfer it to a tubular carbonization furnace. Under a flowing nitrogen atmosphere (120cc / min), heat it up to 500°C at a rate of 3°C / min and keep it warm for 3 hours for carbonization. After the temperature drops to room temperature, the sample is taken out to obtain a porous carbon material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com