Method for preparing 1,4 ¿C cyclohexanedicarboxylate

A technology for dimethyl cyclohexanedicarboxylate and dimethyl phthalate, applied in the field of selective hydrogenation of benzene rings in the presence of a catalyst for aromatic esters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

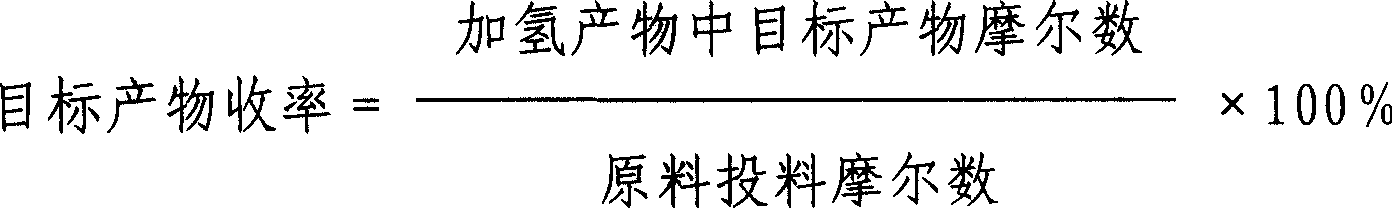

Image

Examples

Embodiment 1

[0017] 2gRuCl 3 ·xH 2 O (about 37% Ru) was dissolved in 325ml deionized water to prepare an impregnating solution, stirred and heated to 60°C, and 20% sodium hydroxide solution was added to adjust the pH value of the impregnating solution to 8. Add 14.3g carrier Al 2 o 3 Powder, continue stirring for 10 minutes. Cool to room temperature and stand for 0.5 hours, add 9.2g of 36% formaldehyde solution dropwise, stir for 1 hour, let stand for 0.5 hours, filter, and wash with deionized water 4 times to obtain the finished catalyst. The particle size of the catalyst is 80-200 head.

Embodiment 2

[0019] Change RuCl 3 ·xH 2 O and carrier Al 2 o 3 The consumption of adding 30% ammonium bicarbonate solution is adjusted to 5 by the dipping liquid pH value, and all the other are with embodiment 1.

Embodiment 3

[0021] Change RuCl 3 ·xH 2 O and carrier Al 2 o 3 The consumption of adding 20% sodium carbonate solution is adjusted to be 8 by the dipping liquid pH value, all the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com