Preparation method and application of silver-containing PET based composite resin material

A composite resin, silver salt technology, applied in the manufacture of rayon, textiles and paper, single-component polyester rayon, etc., can solve the problems of large amount of inorganic components, large particle size, and many process steps, etc. Short preparation cycle, low production cost and ingenious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

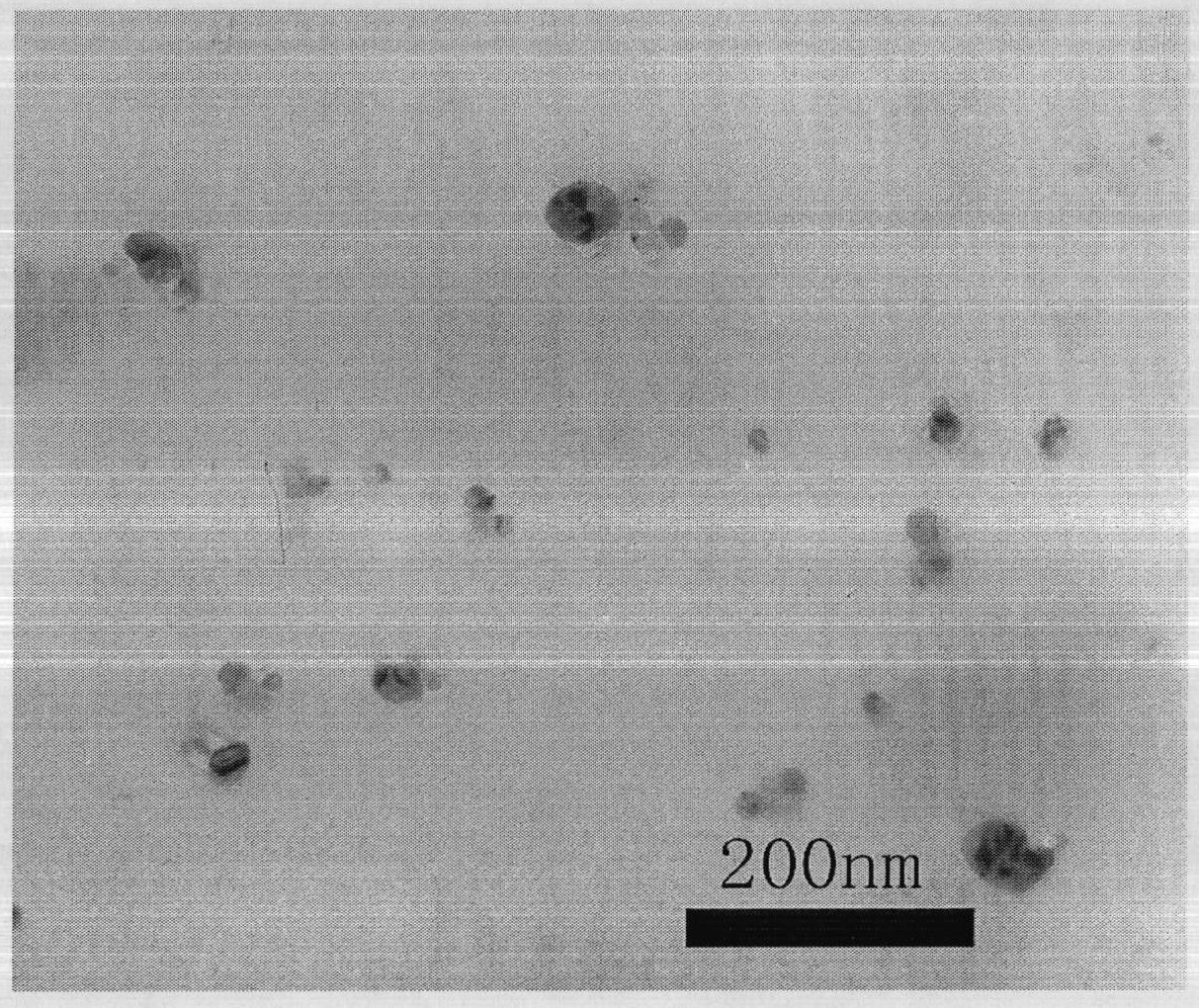

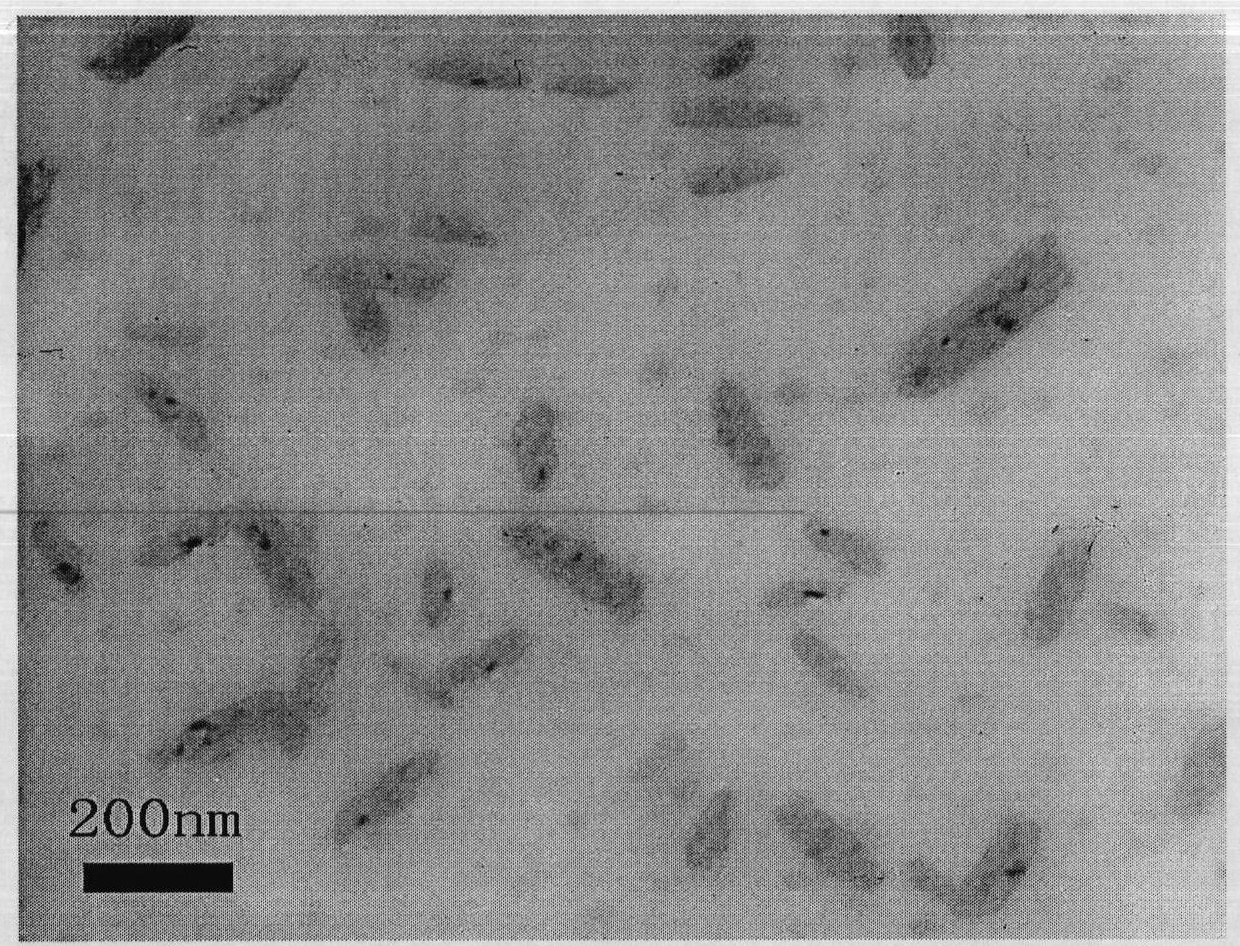

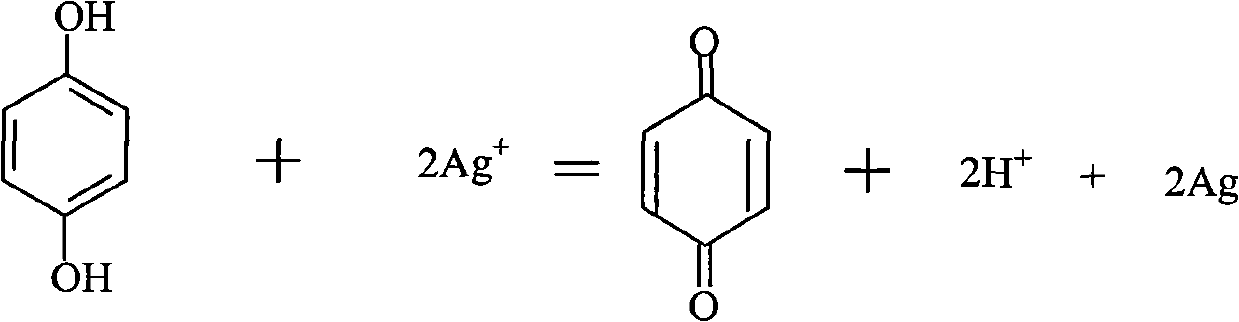

[0028] Weigh 5 grams of PVP and add it to 600ml of ethylene glycol, stir at room temperature until completely dissolved, add 5 grams of AgNO 3 Stir vigorously for 1 h, AgNO 3 Dissolve completely and the solution is light yellow, then add 4.86 grams of hydroquinone and stir vigorously for about 5 minutes until the solution turns reddish brown, then place the system under ultrasonic vibration and continue to react for 1 hour, the solution turns gray, which is silver ethylene glycol Sol. Add the silver glycol sol and 1000 grams of PTA, 0.3 gram of Sb in the 5L polymerizer with nitrogen inlet and outlet and mechanical stirring 2 o 3 , start the mechanical stirring to make it evenly stirred, and at the same time replace the air in the kettle with high-purity nitrogen for 4 times, raise the temperature to 230°C to carry out the esterification reaction, collect the water generated by the reaction to the theoretical volume, and the esterification is completed. Then gradually raise ...

Embodiment 2

[0030] Weigh 4 grams of PVP and add it to 600ml of ethylene glycol, stir at room temperature until completely dissolved, add 10 grams of AgNO 3 Vigorously stirred for 0.8 h, AgNO 3 Dissolve completely and the solution is light yellow, then add 9.71 grams of hydroquinone and stir vigorously for about 5 minutes until the solution turns reddish brown, then place the system under ultrasonic vibration and continue to react for 0.8 hours, the solution turns gray, which is silver ethylene glycol Sol. Add the silver glycol sol and 1000 grams of PTA, 0.3 gram of Sb in the 5L polymerizer with nitrogen inlet and outlet and mechanical stirring 2 o 3 , start the mechanical stirring to make it evenly stirred, and at the same time replace the air in the kettle with high-purity nitrogen for 4 times, raise the temperature to 220°C to carry out the esterification reaction, collect the water generated by the reaction to the theoretical volume, and the esterification is completed. Then gradual...

Embodiment 3

[0032] Weigh 5 grams of PVP and add it to 900ml of ethylene glycol, stir at room temperature until completely dissolved, add 15 grams of AgNO 3 Stir vigorously for 1.2 h, AgNO 3 Dissolve completely and the solution is pale yellow, then add 14.57 grams of hydroquinone and stir vigorously for about 5 minutes until the solution turns reddish brown, then place the system under ultrasonic vibration and continue to react for 1.3 hours, the solution turns gray, which is silver ethylene glycol Sol. Add the obtained silver glycol sol and 1000 grams of DMT, 0.5 gram of magnesium acetate, 0.3 gram of Sb in a 5L polymerization kettle with nitrogen inlet and outlet and mechanical stirring 2 o 3 , start the mechanical stirring to make it evenly stirred, and at the same time replace the air in the kettle with high-purity nitrogen for 4 times, raise the temperature to 240°C to carry out the esterification reaction, collect the water generated by the reaction to the theoretical volume, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com