PETG blow molding film and preparation method thereof

A technology of blown film and anti-blocking agent, which is applied in the field of blown film and its preparation. It can solve the problems of difficult continuous and stable blown film production, huge difference in melt performance, and abnormal molding, etc., and achieves flexible and convenient product replacement and high processing temperature. The effect of wider range and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

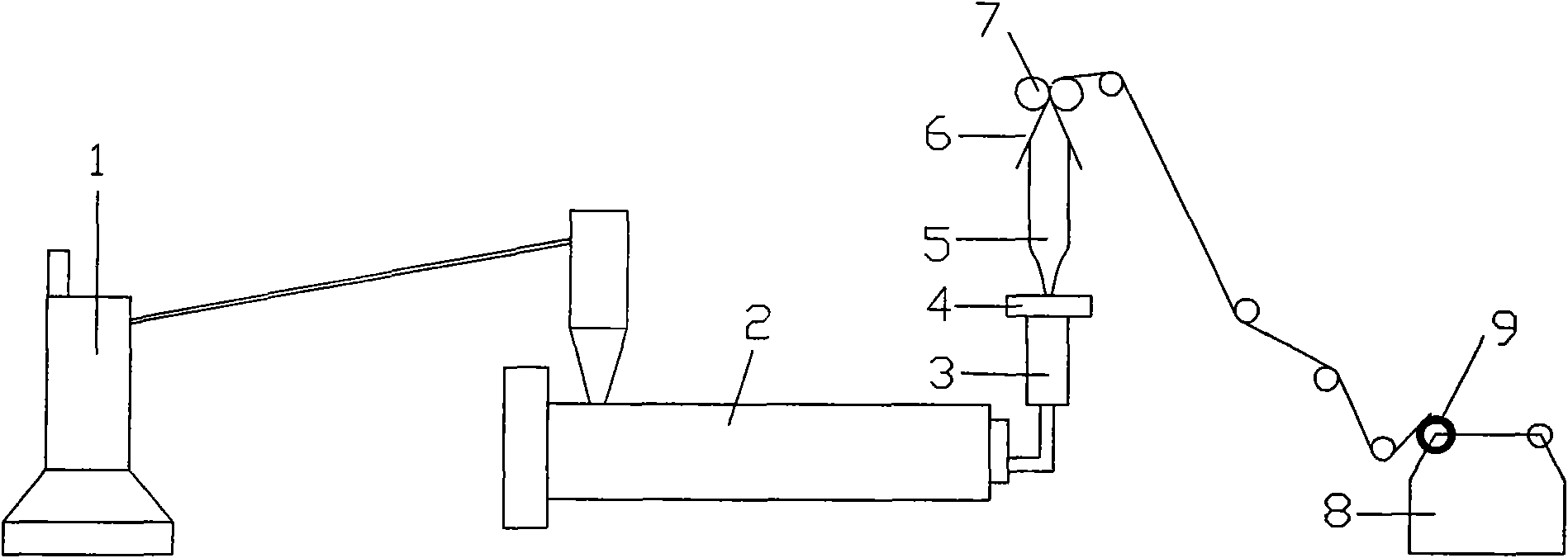

[0036] Embodiment 1: see figure 1 , One-time inflation molding (one-bubble method) to prepare non-shrinkable PETG blown film.

[0037] Material composition: PETG (intrinsic viscosity 0.68) 91.545wt%, silicon dioxide 2.5wt%, ricinoleic acid amide 0.7wt%, stearamidopropyl dimethyl-β-hydroxyethylammonium dihydrogen phosphate 0.25 wt%, bisoxazoline 0.005wt%, modified ethylene propylene rubber 5wt%.

[0038] Blown film preparation: fully mix the materials in a low-speed mixer → send them to a vacuum dryer 1 for drying → transport them to a single-screw extruder 2 for plasticizing and extruding → blow the film once through a film blowing head 3 → curl → divide Cut → finished product.

[0039] Process parameters: Mixing: heating temperature is less than 40°C, speed 650 rpm, mixing for 8-15 minutes; vacuum drying: 65±5°C for 8h, vacuum degree 0.01-0.02Mpa, stop drying when the moisture content is ≤0.008wt%; single The temperature of each section of the screw plasticizing extruder f...

Embodiment 2

[0040] Example 2: see figure 1 , One-time inflation molding to prepare non-shrinkable PETG blown film.

[0041] Material composition: PETG (intrinsic viscosity 0.70) 87.292wt%, artificial talc 3.0wt%, oleic acid amide 1.0wt%, alkyl phosphate diethanolamine salt 0.7wt%, homopolytetracarboxylic dianhydride 0.008wt%, styrene - Ethylene-butadiene-styrene copolymer 8 wt%.

[0042] The extrusion process is as in Example 1. Process parameters before extrusion are as in Example 1. Temperature of each section of plasticizing single-screw extruder: 160±5°C, 180±5°C, 190±5°C, 200±5°C, 215±5°C; connector temperature: 210±5°C; film blowing head temperature : 218±3℃; inflation ratio: 3.2.

Embodiment 3

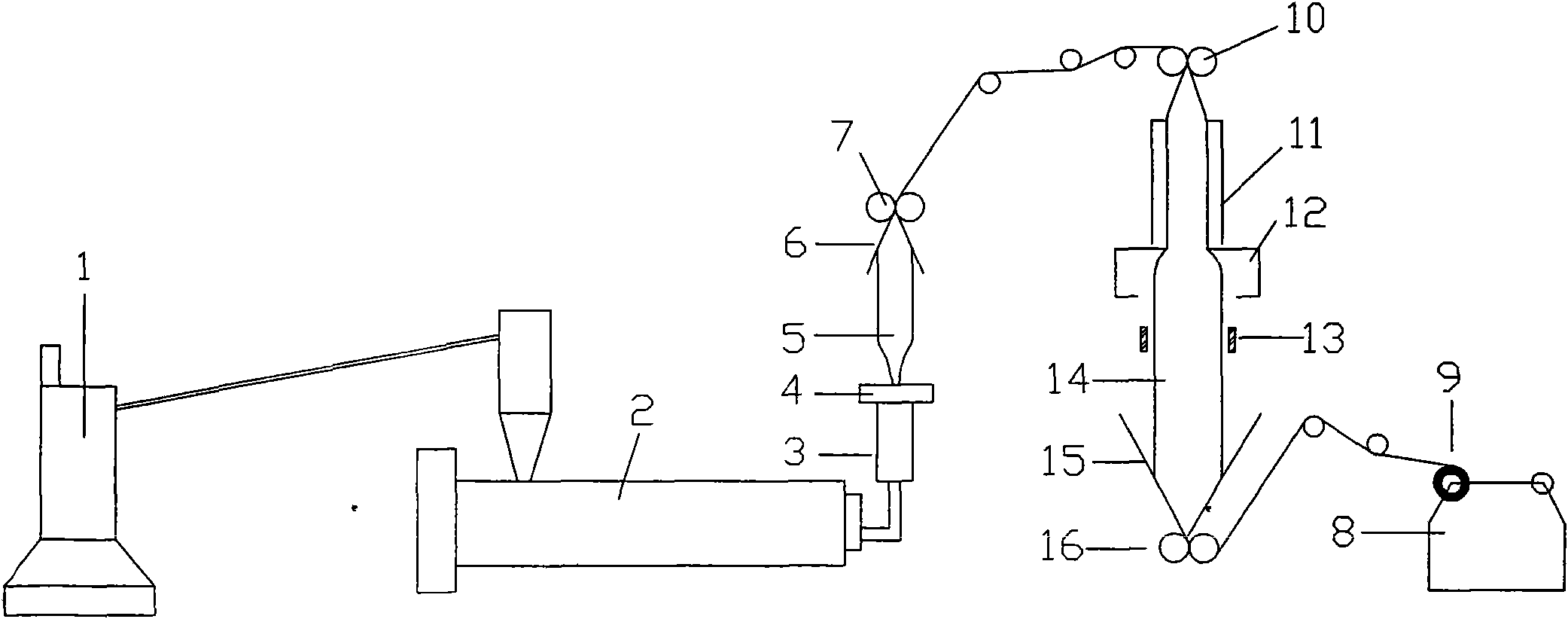

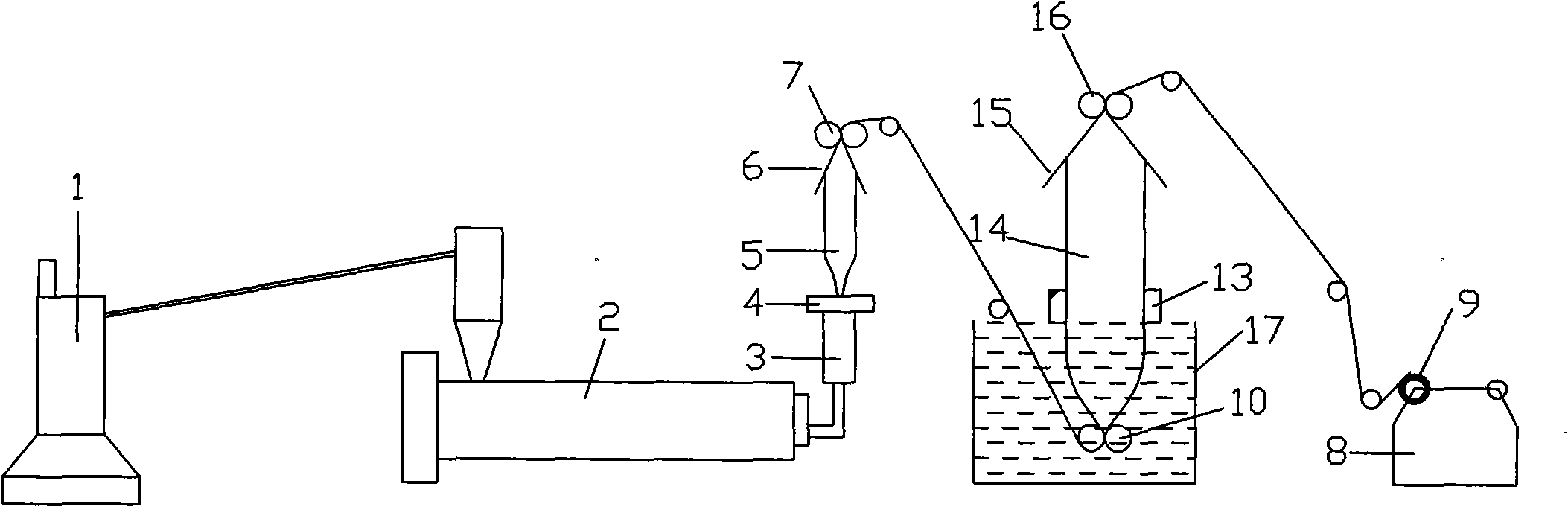

[0043] Embodiment 3: see figure 2 or image 3 , Two-way heat-shrinkable PETG blown film prepared by secondary inflation molding (two-bubble method).

[0044] Material composition: PETG (intrinsic viscosity number 0.72) 90.85wt%, hydrated magnesium silicate 2.9wt%, erucamide 0.8wt%, stearamidopropyl dimethyl-β-hydroxyethyl ammonium nitrate 0.314wt%, Epoxy styrene-acrylic acid random copolymer 0.006wt%, ethylene-vinyl acetate copolymer 5.13wt%.

[0045] Blown film preparation: one-time blown film is the same as Example 1, wherein the temperature of each section of the single-screw extruder: 170±5°C, 185±5°C, 195±5°C, 208±5°C, 217±5°C; connector temperature : 210±5℃; blown film head temperature: 212±3℃; inflation ratio: 1.7. After the primary blown film, the primary blown film is heated by far infrared for 11 (oven temperature: 100±5°C) ( figure 2 ), or water bath heating 17 (water tank temperature: 95 ± 5 ℃ image 3 ) image 3 , for the second cooking film, the second in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com