Alkali-free glass and method for manufacturing same

An alkali-free glass and glass technology, applied in optics, instruments, nonlinear optics, etc., can solve the problems of thermal expansion difference between glass and TFT materials, glass deformation or bending, pixel pitch distortion, etc., to improve portability and reduce melting temperature. , the effect of reducing the processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

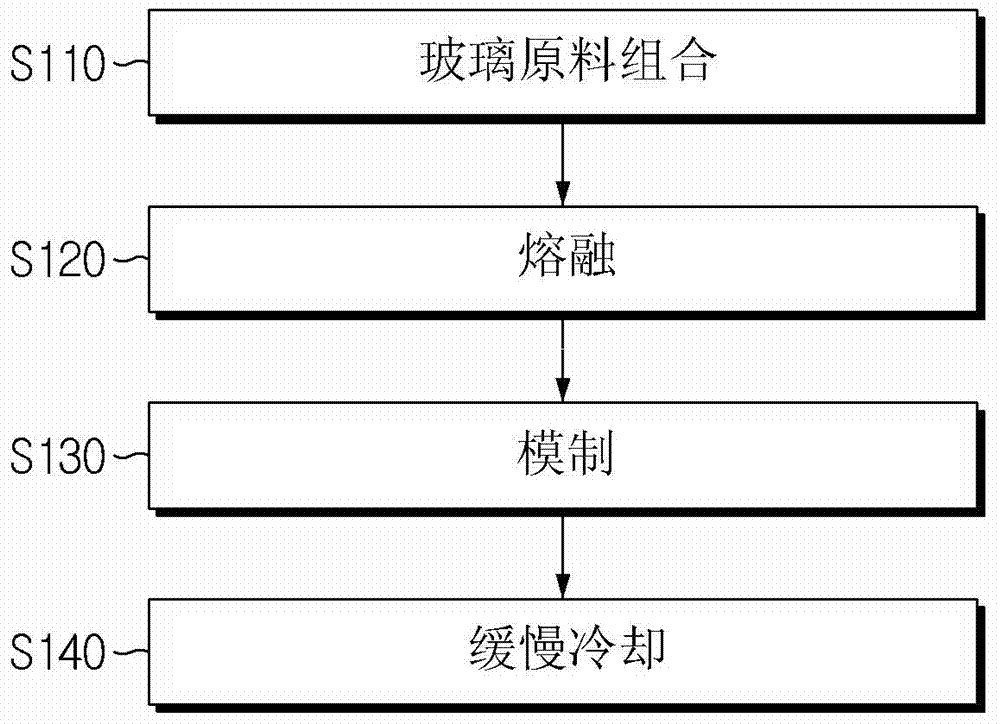

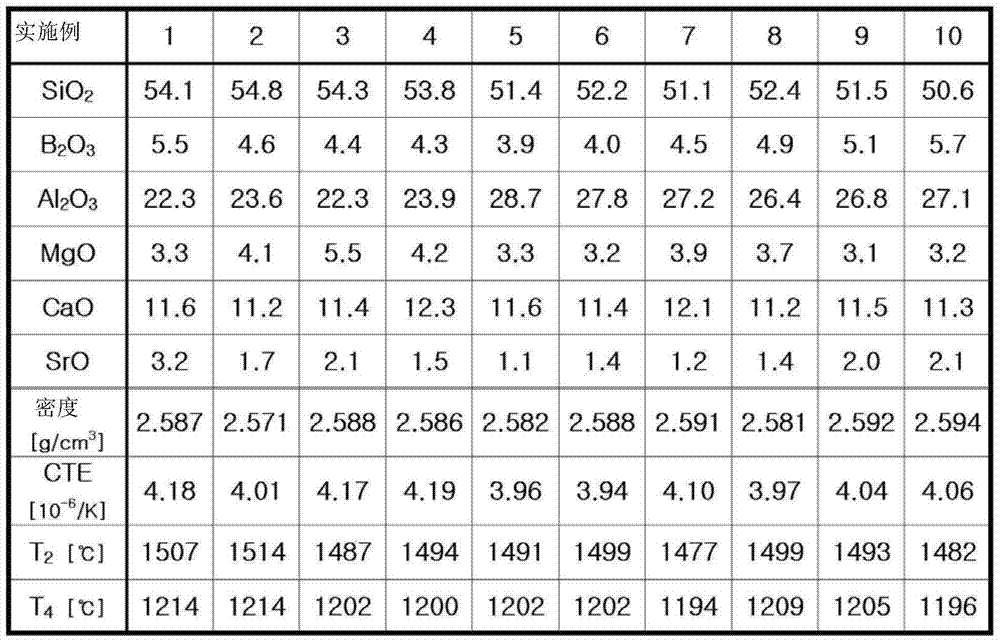

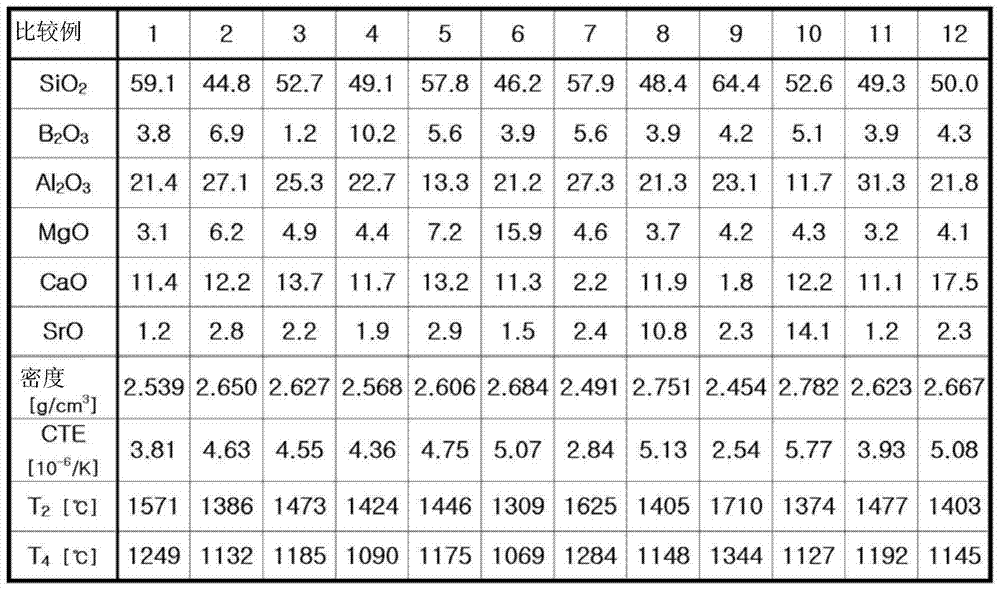

[0058] The raw materials of the respective components were combined so as to have the composition (wt %) shown in Table 1, and the combined material was placed in a platinum crucible and heated to a temperature of 1600° C. for 3 hours to melt it. During melting, stir for 1 hour using a platinum stirrer to make it homogeneous. The molten product was slowly cooled to 730°C to obtain glasses corresponding to the respective examples. The composition of the obtained glass was confirmed by X-ray fluorescence analysis.

[0059] Furthermore, the following properties were evaluated for the resulting glass, namely density, coefficient of thermal expansion, T 2 and T 4 , and the results are shown in Table 1.

[0060]

[0061] The density of glass is measured according to the Archimedes principle.

[0062]

[0063] The average coefficient of thermal expansion of glass is measured using a dilatometer.

[0064] 2 >

[0065] Use a high temperature viscometer to measure the viscosit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| coefficient of thermal expansion | aaaaa | aaaaa |

| coefficient of thermal expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com