Preparation method of fluorine containing coating layer possessing ultra hydrophobic and oleophobic surface reinforced by inorganic ultrafine fiber

A technology of ultra-fine fiber and fluorine-containing coating, which is applied in the device, coating, special surface and other directions of coating liquid on the surface, and achieves the effect of low cost and great application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

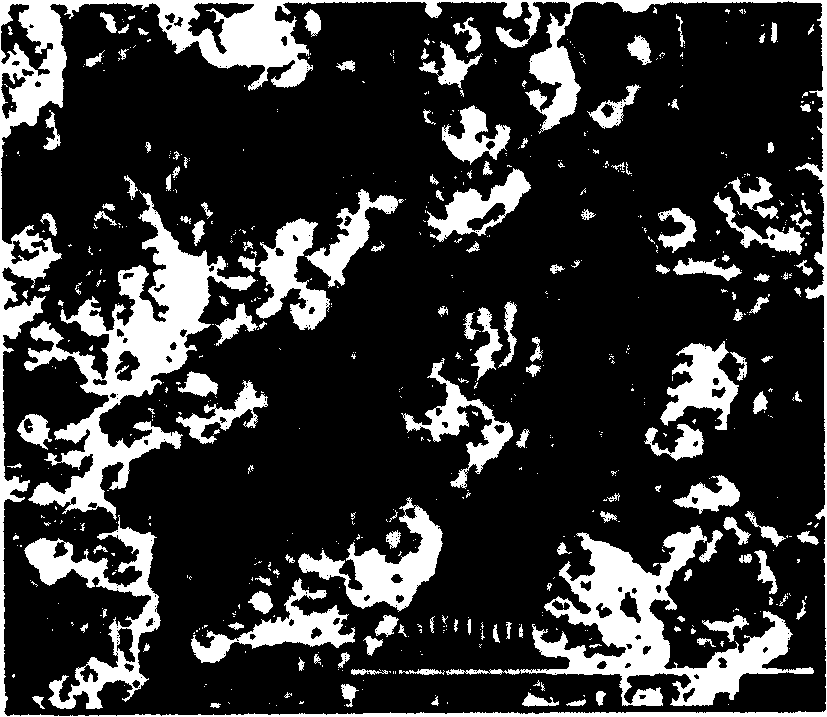

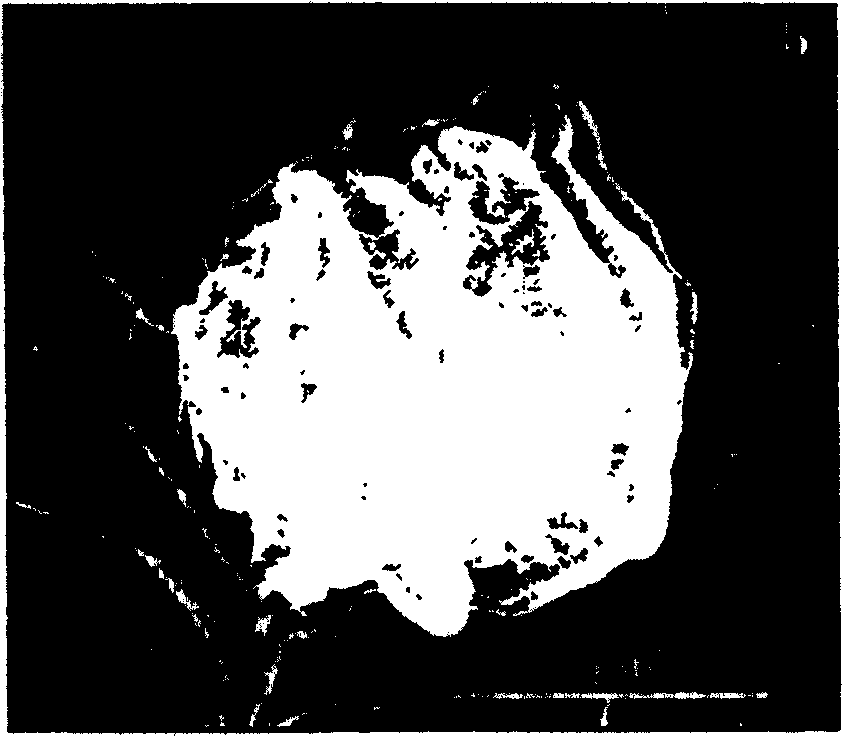

[0032] Small polytetrafluoroethylene emulsion droplets containing 50wt% potassium titanate whiskers (diameter 0.1-5μm, aspect ratio 1-40) with a solid content of 60wt% are uniformly adhered to the The substrate surface was cured at 80°C, the above steps were repeated several times, and sintered at 350°C for 5 hours to obtain a polytetrafluoroethylene / potassium hexatitanate whisker coating. The coating is composed of particles with a diameter of 0.1-200 μm ( figure 1 ), and there is a nano-scale filamentary secondary structure on a single particle ( figure 2 ). The contact angle between coating and water is 155°( image 3 ), rolling angle 10°; contact angle with glycerin 140°( Figure 4 ); the contact angle with salad oil is 120°( Figure 5 ), coating hardness 4H (GB-T6739-1996).

Embodiment 2

[0038] Small polyvinylidene fluoride emulsion droplets containing 1wt% magnesium salt whiskers (diameter 0.1-2μm, aspect ratio 20-100) with a solid content of 15% are uniformly adhered to the The substrate surface was cured at 100°C, the above steps were repeated several times, and sintered at 380°C for 0.5 hour to obtain a polyvinylidene fluoride / magnesium salt whisker coating with micro / nano secondary structure characteristics. The coating is superhydrophobic and oleophobic. The contact angle of water on the coating surface is 160°, and the rolling angle is 10°; the contact angle of glycerin on the coating surface is 144°; the contact angle of salad oil on the coating surface is 128°. Coating thickness about 50 μm, see image 3 . Coating hardness 3H.

Embodiment 3

[0042] Small polyvinyl fluoride emulsion droplets containing 45wt% titanium oxide whiskers (diameter 0.5-3μm, aspect ratio 20-60) with a solid content of 60wt% are uniformly adhered to the substrate in a single layer or several layers Surface, 90°C. After curing, repeat the above steps several times, and sinter at 370° C. for 1 hour to obtain a polyvinyl fluoride / titanium oxide whisker coating with micro / nano secondary structure characteristics. The coating is superhydrophobic and oleophobic. The contact angle of water on the coating surface is 156°, and the rolling angle is 10°; the contact angle of glycerin on the coating surface is 142°; the contact angle of salad oil on the coating surface is 124°. The hardness of the coating is 4H.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com