Simulation stone facing concrete element and method for producing the same

A production method and concrete technology, applied in the direction of chemical instruments and methods, underwater structures, building structures, etc., can solve the problems of increased production cost, not beautiful enough, non-slip, etc. beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. The present invention is not limited to the following examples.

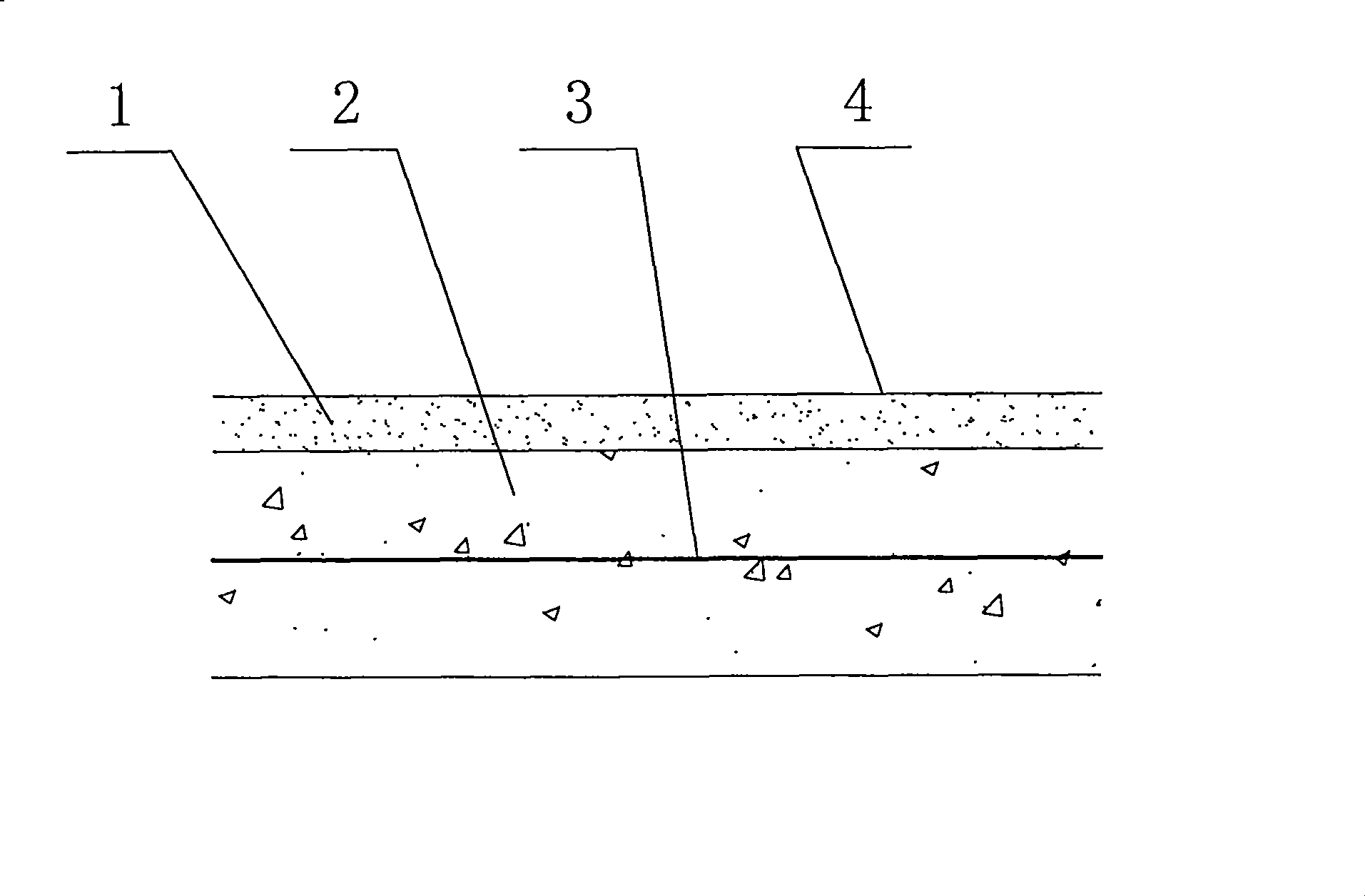

[0024] Referring to the accompanying drawings, the artificial stone surface layer concrete component is composed of an artificial stone surface layer (1) and a fiber concrete layer (2). In order to increase the strength, a steel skeleton (3) is placed in the fiber concrete layer (2). The artificial stone surface layer (1) is prepared from colored cement, stones, quartz sand and water, and its weight ratio is: 1:0.4-0.8:0.4-0.8:0.25-0.38. In order to make the surface of the component consistent with the effect of marble or granite veneer, the stones are marble or granite crushed stones with a continuous particle size of φ3mm-φ5mm. The fiber concrete layer (2) is prepared by cement, yellow sand, stone, fly ash, water reducing agent, steel fiber or glass fiber or steel fiber and gla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com