Water-permeable bricks prepared from granite stone waste materials and preparation method thereof

A stone waste and granite technology, applied in the field of building materials, can solve the waste of stone resources and other problems, achieve the effect of solving environmental protection problems, high strength, and expanding the scope of raw material supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

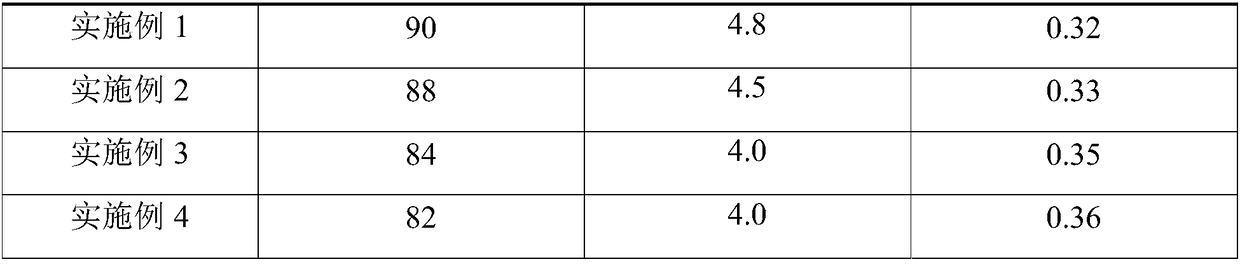

Embodiment 1

[0024] 1-5mm granite stone particles, 1-5mm high-alumina bauxite aggregate particles, 200-mesh granite stone saw mud, 325-mesh high-alumina bauxite fine powder, 325-mesh kaolin, and aluminum sol solution with a mass concentration of 25% respectively according to 57 : 12:10:7:7:7 weight ratio mixed evenly to make permeable brick mixture.

[0025] Fill the above-mentioned permeable brick mixture into the metal brick mold of the press, press molding at one time, and the molding pressure is 23MPa; after the pressed brick is dried at 110°C for 9 hours, it is fired at a high temperature of 1100°C, and the granite is obtained after cooling Stone waste permeable bricks. The performance indicators of permeable bricks are shown in Table 1.

Embodiment 2

[0027] 1-5mm granite stone particles, 1-5mm high-alumina bauxite aggregate particles, 200-mesh granite stone sawing mud, 325-mesh high-alumina bauxite fine powder, 325-mesh Suzhou soil, and aluminum sol solution with a mass concentration of 25% respectively according to The weight ratio of 59:10:12:7:6:6 is mixed evenly to make a permeable brick mixture.

[0028] Fill the above-mentioned permeable brick mixture into the metal brick mold of the press, press molding at one time, and the molding pressure is 25MPa; after the pressed brick is dried at 110°C for 9 hours, it is fired at a high temperature of 1110°C, and the granite is obtained after cooling Stone waste permeable bricks. The performance indicators of permeable bricks are shown in Table 1.

Embodiment 3

[0030] 1-5mm granite stone particles, 1-5mm high-alumina bauxite aggregate particles, 200-mesh granite stone saw mud, 325-mesh high-alumina bauxite fine powder, 325-mesh bentonite, and aluminum sol solution with a mass concentration of 25% respectively according to 60 : 10: 15: 5: 5: 5 weight ratio mixed evenly to make permeable brick mixture.

[0031] Fill the above-mentioned permeable brick mixture into the metal brick mold of the press, press molding at one time, and the molding pressure is 23MPa; after the pressed brick is dried at 110°C for 9 hours, it is fired at a high temperature of 1120°C, and the granite is obtained after cooling Stone waste permeable bricks. The performance indicators of permeable bricks are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com