Method of forming surface seeded particulate

a technology of seeded particulate and surface, which is applied in the direction of applications, flooring, ways, etc., can solve the problems of difficult to achieve uniform surface area application and difficult to achieve large surface area uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

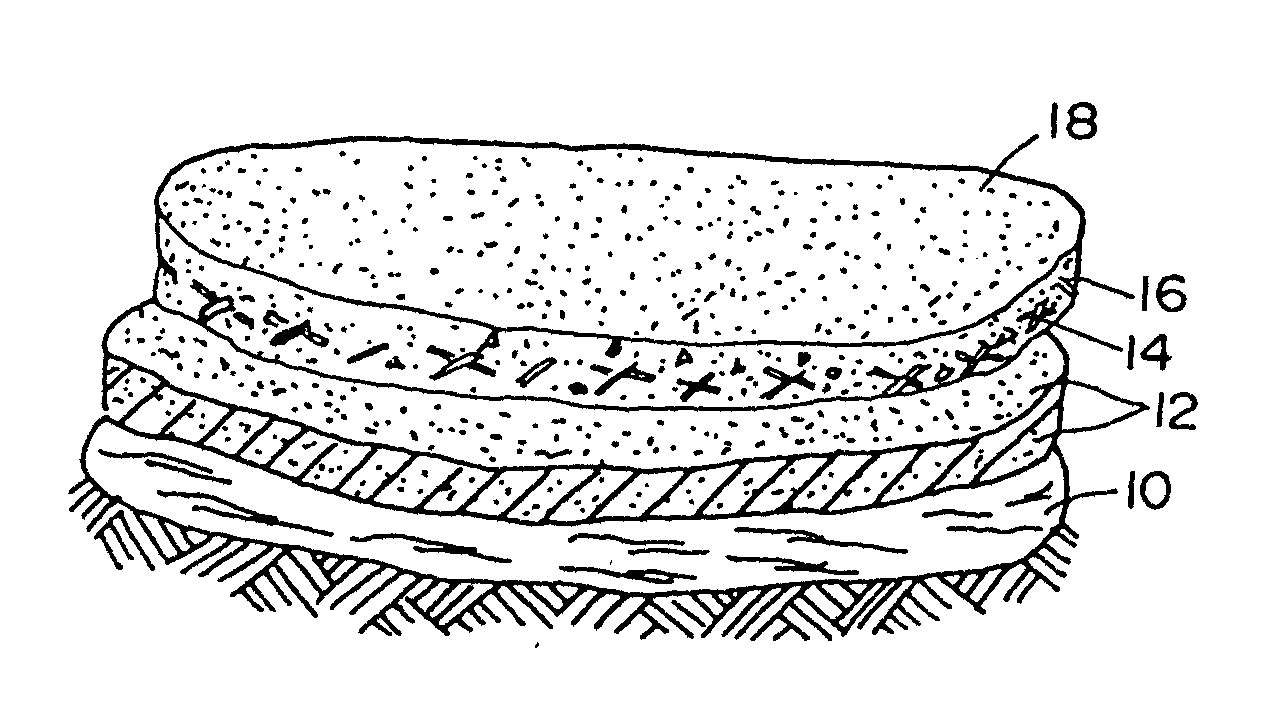

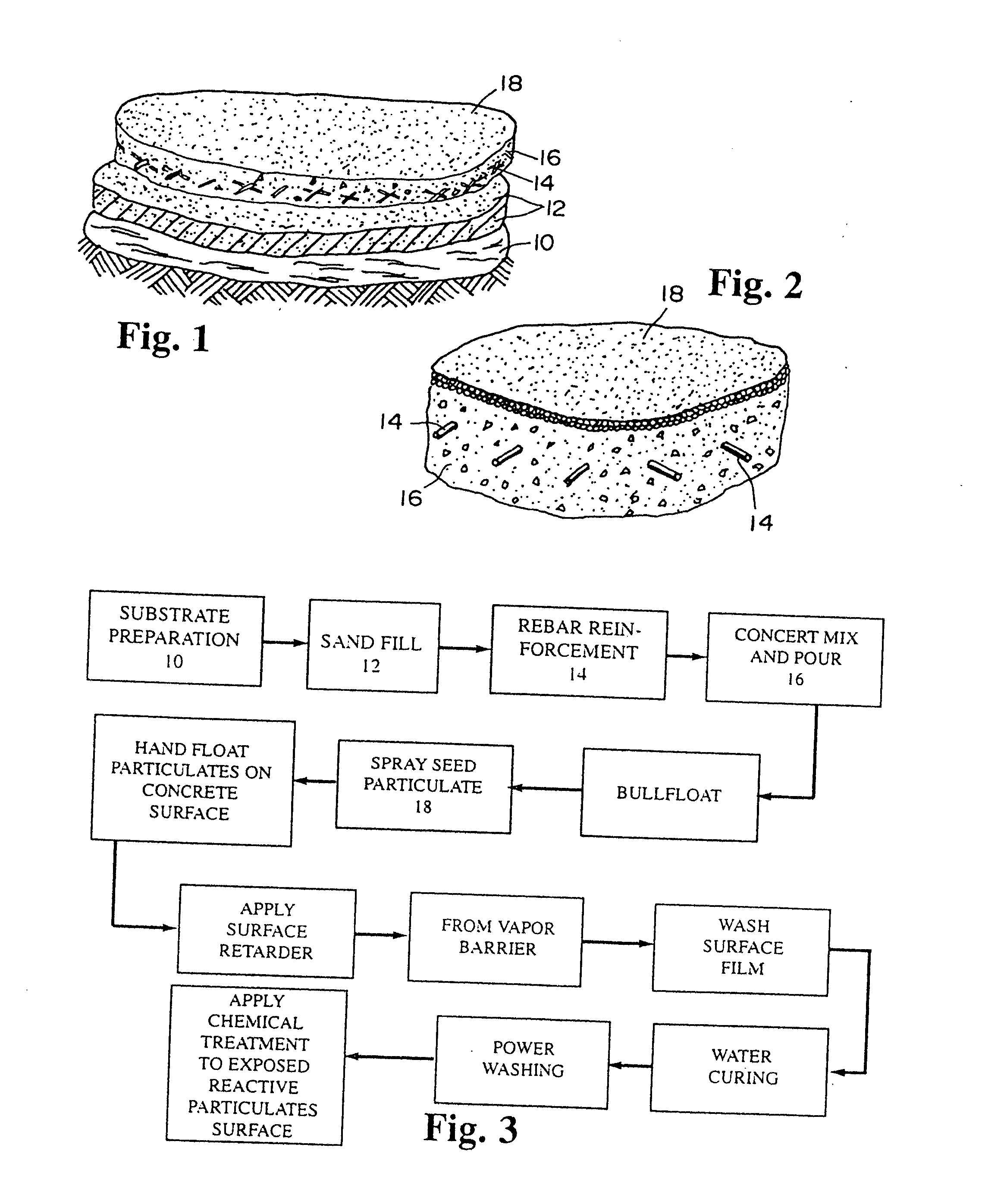

[0031] Referring now to the drawings wherein the showings are for purposes of illustrating preferred embodiments of the present invention only, and not for purposes of limiting the same, the surface seeded exposed particulate concrete and method of producing the same is pictorially and schematically illustrated. The particulate may be potentially reactive with the concrete mixture 16. For example, the particulate 18 may comprise glass, such as silica glass, organic materials, such as sea shells of marine animals and mollusk, and other various metals and composite materials. Alternatively, the particulate 18 may be an aggregate that does not react with the concrete mixture. For example, the particulate may comprise coarse sand, such as Monterey Aquarium (Grade) coarse sand. Preferably, the particulate is characterized by having a mean average diameter size of approximately one-eighth inch diameter. The particulate may possess a rounded external surface configuration. Alternatively, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean diameter size | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com