Foaming ceramic light sheet material prepared from granite scraps and preparation method thereof

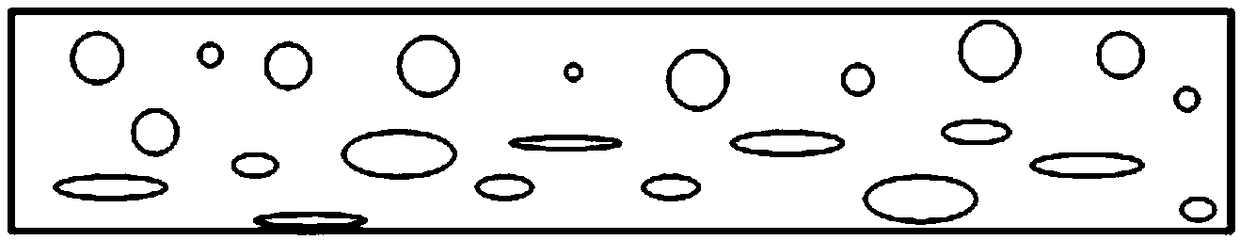

A technology of granite waste and foamed ceramics, which is applied in the production and application of ceramic products and ceramic materials, can solve the problems of long foaming time, high temperature, and high cost, and achieve improved uniformity, good overall uniformity, and excellent quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

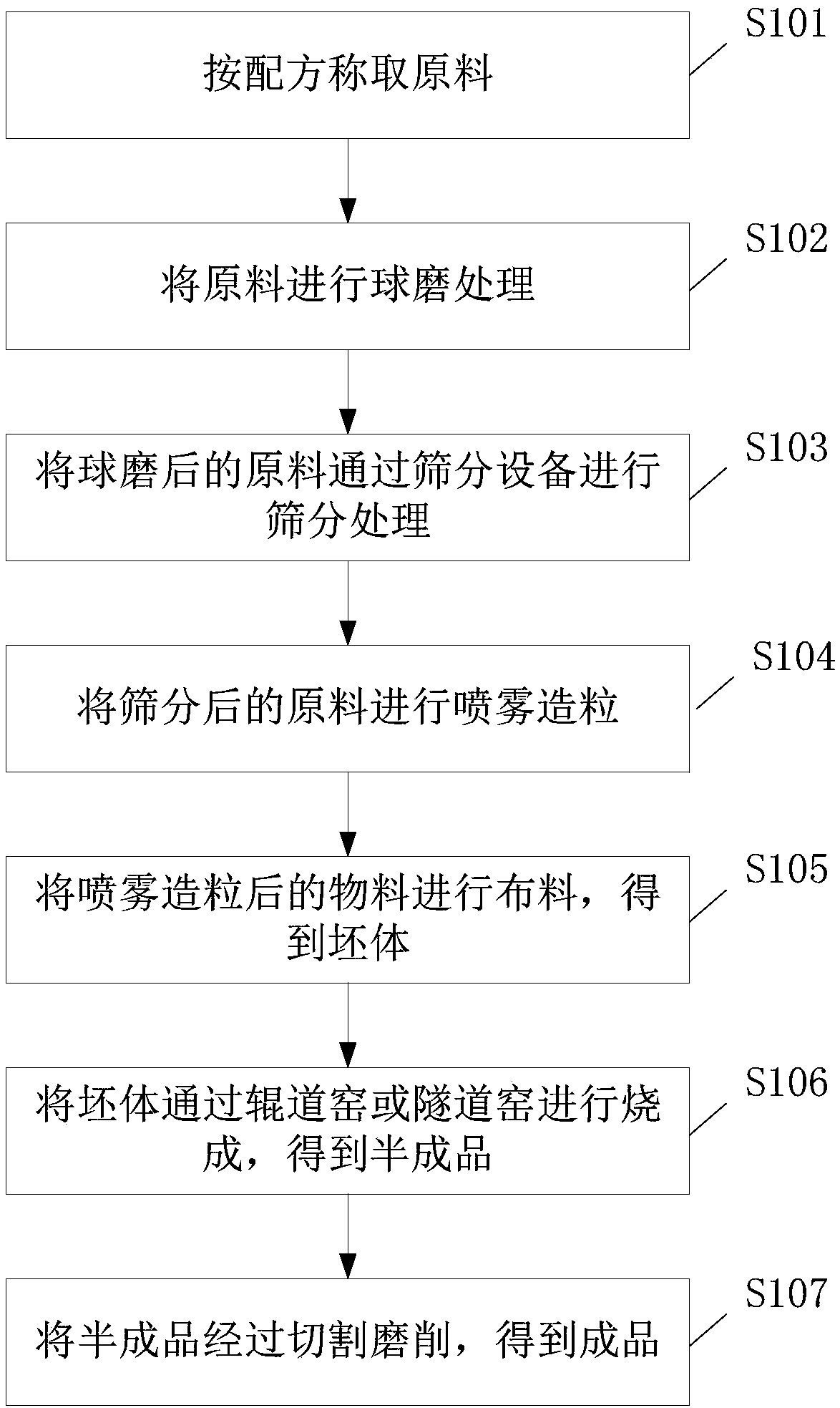

Method used

Image

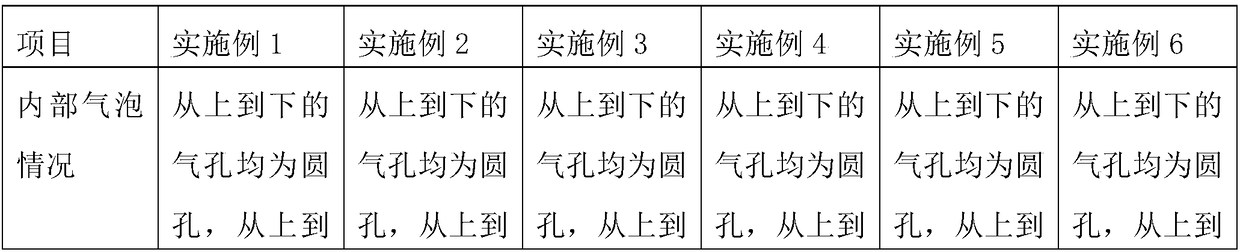

Examples

Embodiment 1

[0077] (1) take raw material by formula, described raw material comprises:

[0078] Granite waste 70%, clay 20%, foaming agent 5%, manganese dioxide 5%;

[0079] (2) ball milling the raw material;

[0080] (3) The raw materials after ball milling are screened through screening equipment;

[0081] (4) carrying out spray granulation with the raw material after screening;

[0082] (5) distributing the raw materials after spray granulation to obtain green bodies;

[0083] (6) firing the green body through a roller kiln to obtain a semi-finished product;

[0084] (7) Cut and grind the semi-finished product to obtain the finished product.

[0085] Among them, the firing methods of the roller kiln include:

[0086] (a) Raise the temperature to 800°C and keep it at 800°C for 20 minutes, wherein the heating rate from 0°C to 400°C is 10°C / min, and the heating rate from 400°C to 800°C is 3°C / min;

[0087] (b) Raise the temperature to 1150°C and keep it at the highest temperature fo...

Embodiment 2

[0090] (1) take raw material by formula, described raw material comprises:

[0091] Granite waste 80%, clay 18%, foaming agent 1%, manganese dioxide 1%;

[0092] (2) ball milling the raw material;

[0093] (3) The raw materials after ball milling are screened through screening equipment;

[0094] (4) carrying out spray granulation with the raw material after screening;

[0095] (5) distributing the raw materials after spray granulation to obtain green bodies;

[0096] (6) firing the green body through a roller kiln to obtain a semi-finished product;

[0097] (7) Cut and grind the semi-finished product to obtain the finished product.

[0098] The firing methods of roller kiln include:

[0099] (a) Raise the temperature to 820°C and keep it at 820°C for 15 minutes, wherein the heating rate from 0°C to 400°C is 15°C / min, and the heating rate from 400°C to 820°C is 5°C / min;

[0100] (b) Raise the temperature to 1170°C and keep it at the highest temperature for 30 minutes, wh...

Embodiment 3

[0103] (1) take raw material by formula, described raw material comprises:

[0104] Granite waste 75%, clay 20%, foaming agent 2%, manganese dioxide 3%;

[0105] (2) ball milling the raw material;

[0106] (3) The raw materials after ball milling are screened through screening equipment;

[0107] (4) carrying out spray granulation with the raw material after screening;

[0108] (5) distributing the raw materials after spray granulation to obtain green bodies;

[0109] (6) firing the green body through a roller kiln to obtain a semi-finished product;

[0110] (7) Cut and grind the semi-finished product to obtain the finished product.

[0111] The firing methods of roller kiln include:

[0112] (a) Raise the temperature to 830°C and keep it at 830°C for 25 minutes, wherein the heating rate from 0°C to 400°C is 15°C / min, and the heating rate from 400°C to 830°C is 5°C / min;

[0113] (b) Raise the temperature to 1180°C, and keep it at the highest temperature for 0-60min, wher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com