Imitated stone environment-friendly concrete road brick and making method thereof

An environmentally friendly concrete and imitation stone technology, applied in the field of pavement brick manufacturing, can solve the problems of low technical barriers, many customer complaints, easy falling off of the surface layer, etc., to achieve outstanding appearance, beautify urban landscape construction, and solve the effect of efflorescence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

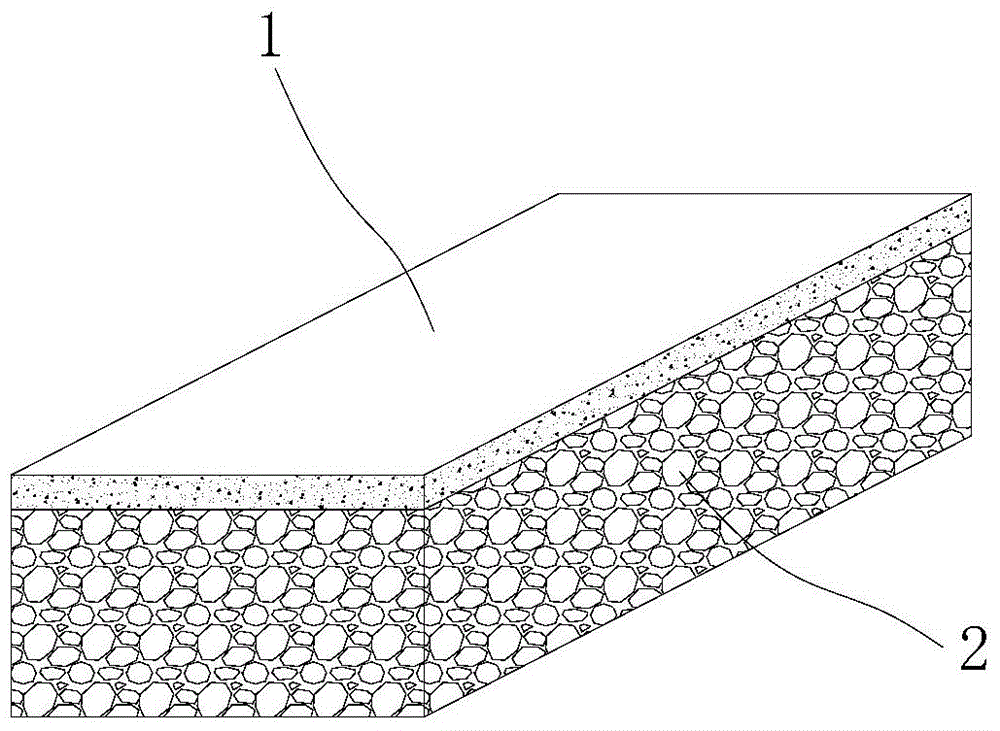

[0031] see figure 1 , a stone imitation environment-friendly concrete pavement brick, comprising a surface layer 1 and a base layer 2; the thickness of the surface layer is 5-12mm, comprising 5-30% cement by weight, 70-95% quartz sand by weight or At least one of granite crushing sand or tailings sand, one of ethylene vinyl acetate or acrylic resin or water-based epoxy resin with a weight ratio of 5-30%; the thickness of the base layer is 45-115mm, mainly including cement 3-30 20%, mineral powder 0-20%, fly ash 0-10%, fly ash slag 10-50%, iron ore beneficiation debris with a fineness modulus of 1.0-3.0 10-40%; particle size 2- 10mm iron ore beneficiation debris 35-50%.

[0032] In recent years, as the country's environmental protection has ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com