Soil pressure shield waste soil flow plasticity improvement method suitable for sandy cobble stratum

The technology of sand and pebble and stratum is applied in the field of soil pressure shield slag flow plastic improvement, which can solve the problems of difficulty in improving sand and pebble slag, high-strength slag stagnation, frequent tool changing operations, etc. The effect of reducing maintenance costs and improving excavation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

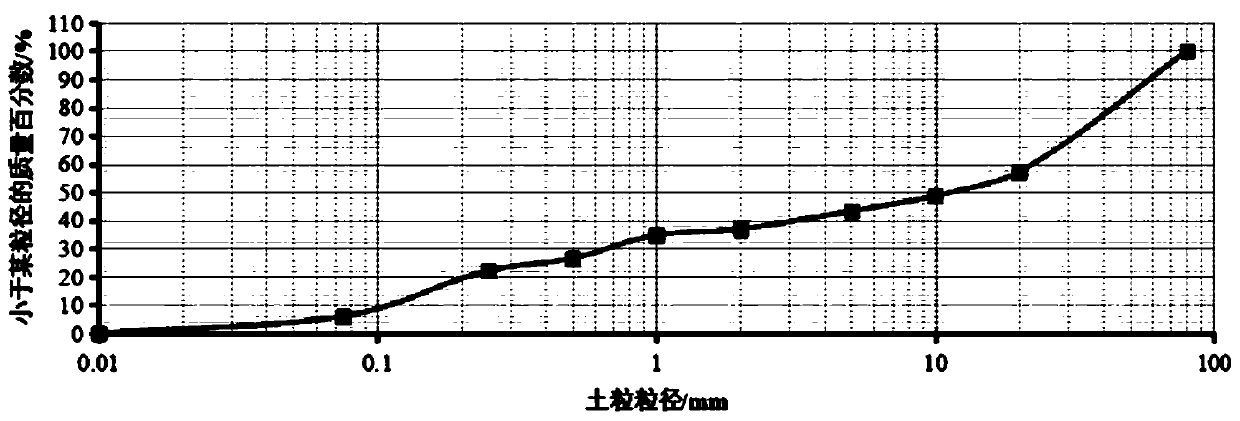

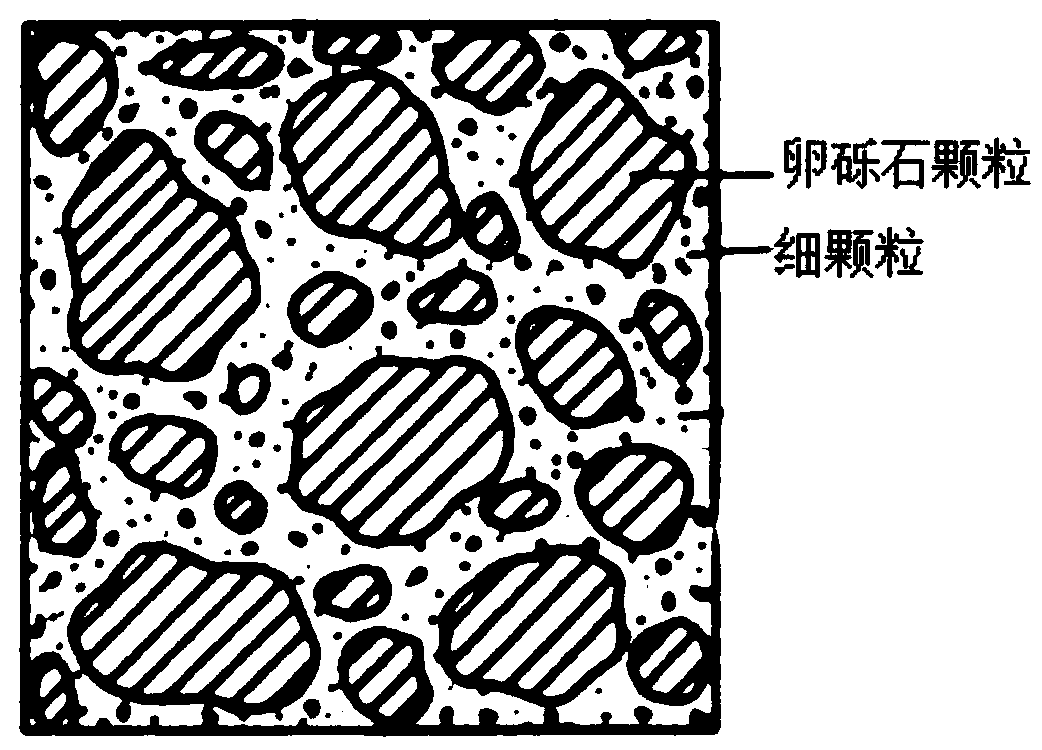

[0064] The origin of the sand and pebble strata in the Chengdu area has gradually changed from the origin of the upper Pleistocene alluvium and flood to the origin of ice debt, ice water accumulation, and alluvial flood in the Middle Pleistocene to the origin of late Pleistocene ice water-flowing water accumulation, and finally to the cause of modern river terraces-floodplain; The pebble layer is mainly distributed in the plain part, most of which are 13-27 meters thick, the maximum thickness can exceed 30 meters, and the buried depth is 1-3 meters, and the maximum buried depth can exceed 7 meters. Horizontally, from northwest to southeast, the burial depth of sand and pebble layers increases from small to large, the mud content from small to large, and the ratio of sand and pebbles from small to large. Vertically, the degree of weathering of the sand and pebble strata gradually weakens from old to new, and the density and bearing pressure of the pebble strata increase with dep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com