Method for preparing niobium pentoxide from low-grade niobium ore

A niobium pentoxide, low-grade technology, applied in chemical instruments and methods, niobium compounds, inorganic chemistry, etc., can solve the problems of large acid consumption, complex intercalation relationship, and difficult beneficiation and smelting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

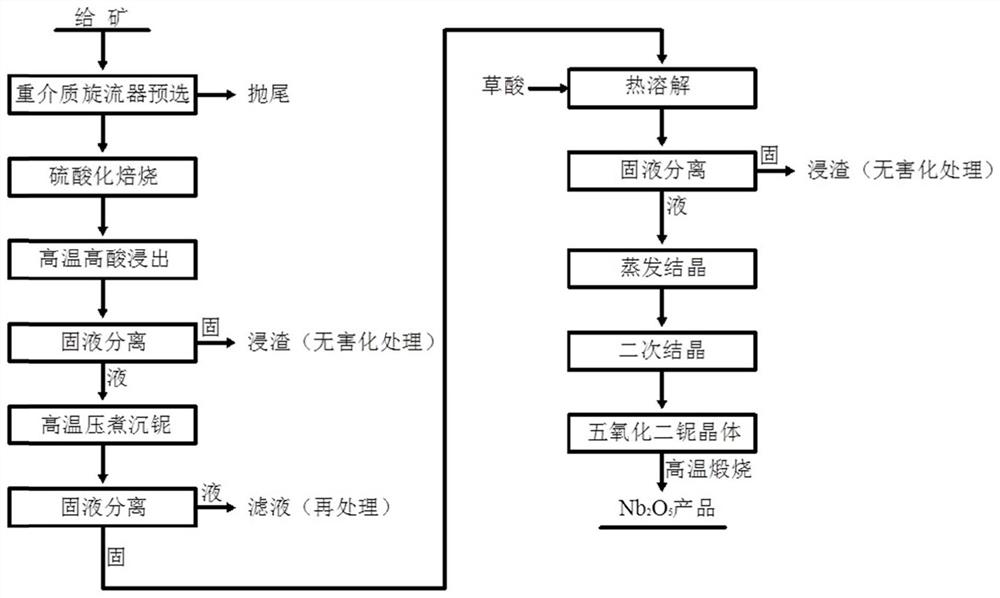

[0034] The method for preparing niobium pentoxide from low-grade niobium ore of the present embodiment, the process flow chart is as follows figure 1 shown, including the following steps:

[0035] 1) The niobium ore is crushed to 0.5-3mm, and the pre-selected ore is obtained through the pre-selection and tailing of the non-pressure two-product heavy-medium cyclone; the medium density of the heavy-medium cyclone is 2.45g / cm 3 , the medium is a suspension of ferrosilicon powder and water, and the working pressure (media inlet pressure) is 0.15MPa.

[0036] 2) Finely grind the pre-selected concentrate until 100% is less than 0.074mm, first carry out sulfate roasting, and then carry out sulfuric acid leaching;

[0037]Sulfation roasting is to mix and roast the finely ground pre-selected concentrate and concentrated sulfuric acid, the amount of concentrated sulfuric acid is 50% of the ore weight, the roasting temperature is 210°C, and the roasting time is 120 minutes.

[0038] Su...

Embodiment 2-3

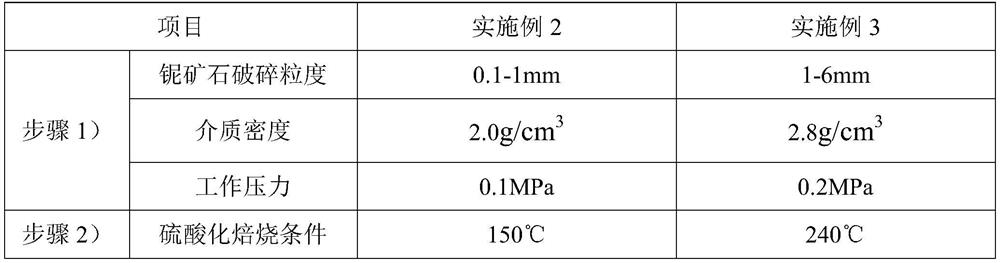

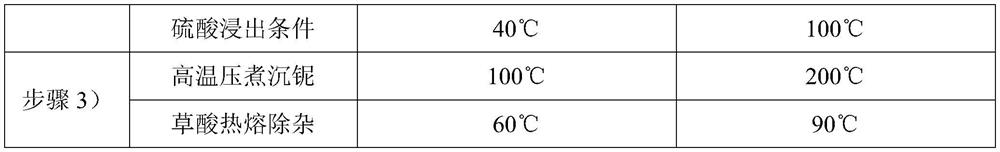

[0045] The method for preparing niobium pentoxide from low-grade niobium ore in Examples 2-3 is basically the same as that in Example 1, and the differences in specific process parameters are listed in Table 1.

[0046] The process parameters of the method of table 1 embodiment 2-3

[0047]

[0048]

[0049] 2. Experimental example

[0050] This experimental example takes Examples 1-3 as examples to illustrate the test results of the method of the present invention, which are specifically shown in Tables 2-4.

[0051] The test result of the method of table 2 embodiment 1

[0052]

[0053] The above test results show that: raw ore is crushed—preselected by dense medium cyclone—sulfated roasting—leaching—high temperature pressure cooking to sink niobium—oxalic acid hot melting—chemical impurity removal—crystallization and decomposition to refine niobium pentoxide products. The tailing rate of pre-selection in the cyclone is 93.76%, the recovery rate of useful mineral ...

Embodiment 2

[0057] In Example 2, the heavy medium cyclone pre-selected tailings was 90.74%, the recovery rate of useful mineral niobium was 83.56%, and the tailing effect was ideal; the pre-selected concentrate was then leached by sulfate roasting-high temperature pressure cooking to sink niobium; niobium leaching rate 89.67%, niobium precipitation rate 99.86%, high niobium precipitation efficiency, low loss rate, niobium metallurgical recovery rate 89.54%; finally after oxalic acid hot melting to remove impurities, crystallization and decomposition to refine niobium pentoxide, the product purity is 99.91%, the total niobium dressing and smelting The recovery rate is 74.82%, which greatly improves the utilization rate of niobium resources.

[0058] The test result of the method of table 4 embodiment 3

[0059]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com