High polymer grouting repair method for treating ballastless track foundation bed mud pumping

A technology of mud-flushing and ballastless track, which is applied in the field of geotechnical engineering, can solve problems such as insufficient filling of the empty area at the bottom of the base plate, difficulty in eradicating the mud-flushing disease, and poor long-term service performance, so as to ensure long-term Normal serviceability, reduced whiplash effect, strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below with reference to the embodiments and the accompanying drawings, and the features of the following embodiments and implementations may be combined with each other without conflict.

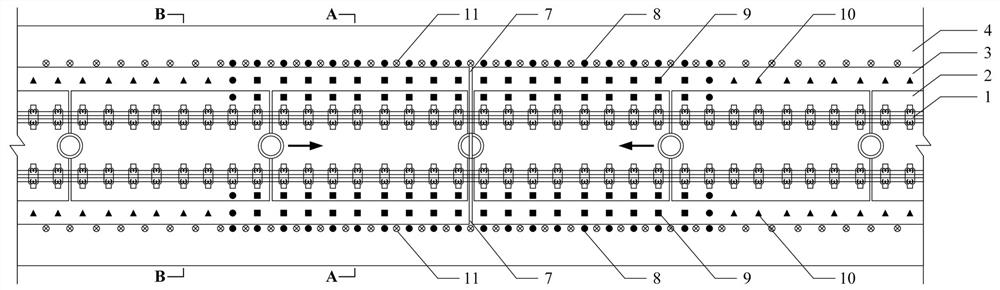

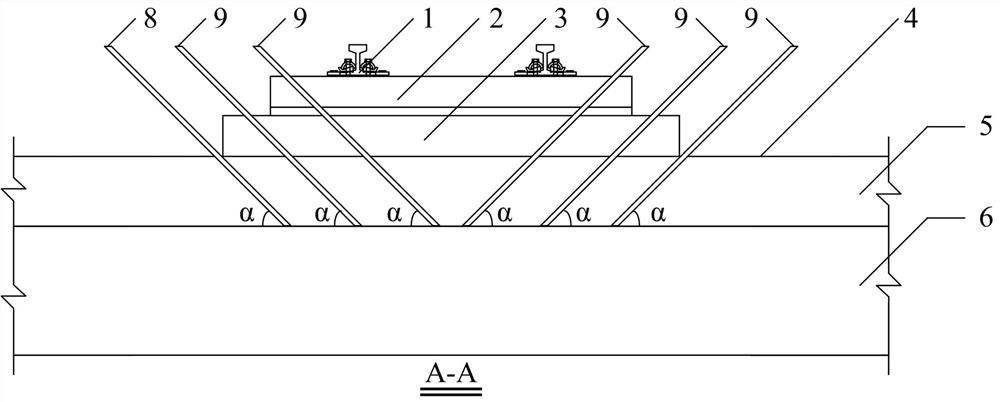

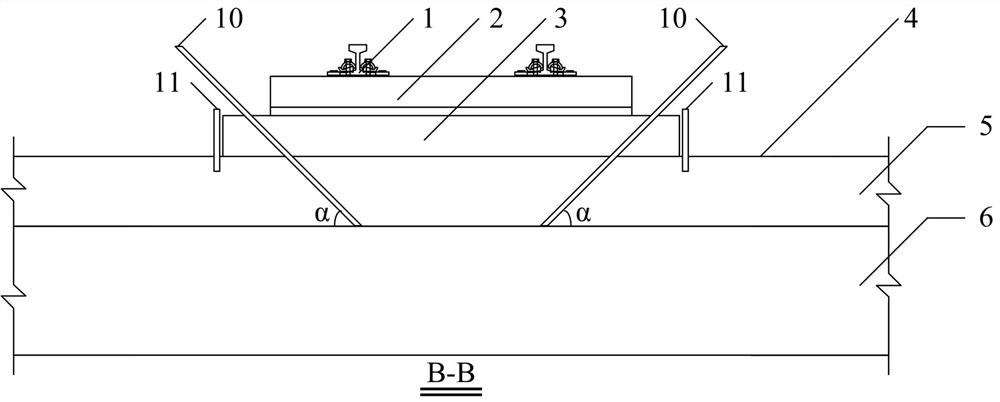

[0032] like figure 1 As shown in the figure, the basic components of the ballastless track structure of the high-speed railway from top to bottom are the rail and fastener system 1, the track plate 2, the base plate 3, the base bed surface layer 5 and the base bed bottom layer 6, of which the rigid track plate 2 and the base A layer of cement emulsified asphalt mortar layer is arranged between the plates 3 as a buffer layer, and the surface of the foundation bed of the shoulder part outside the base plate is covered with a concrete sealing layer 4 with a slope of 4%, which is convenient for the surface drainage of the track structure. In order to prevent the bulging plate disease of the base plate under high temperature, a 2 cm expansion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com