Anti-freezing water-resisting layer and roadbed

A water-resistant layer and subgrade technology, which is applied in the direction of roads, roads, buildings, etc., can solve the problems of subgrade frost heaving, high water content of subgrade, and mud turning, so as to achieve stable water content and avoid the effect of subgrade frost heaving or mud turning

Pending Publication Date: 2019-11-05

CHINA COMM NORTH ROAD & BRIDGE +1

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] This application provides an antifreeze water-repellent layer and roadbed to solve the problem of frost heaving and muddying of the roadbed caused by the high water content of the roadbed

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0066] Embodiment 1: Adopt geotechnical barrier, set fault material=100*(26+0.5+0.5)=2700㎡ in total, processing cost=2700*38=113400, digging and rolling earthwork=100*26*0.5=1300m 3 , treatment cost = 1300*14.05 = 18265 yuan, the total cost is 131665 yuan, the treatment effect is remarkable, reliable, and the cost is low.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

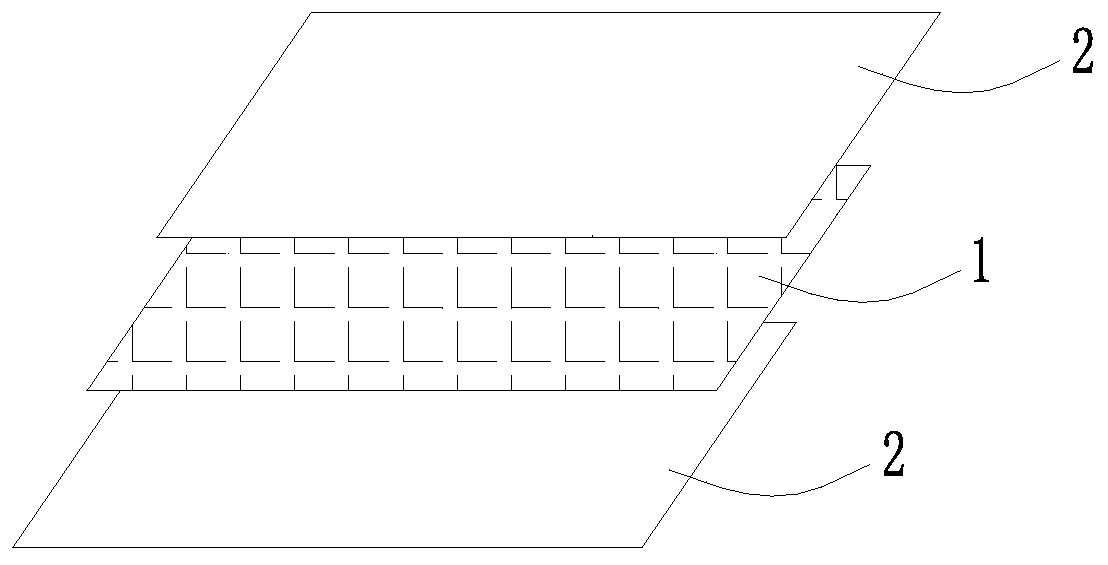

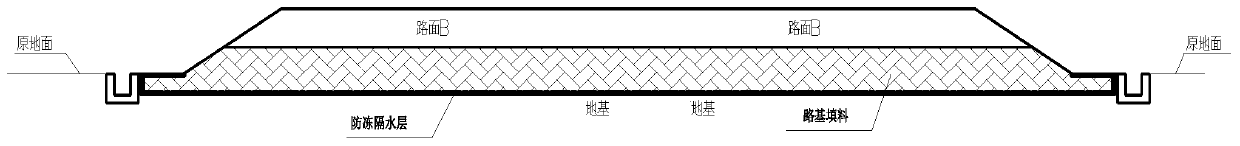

The application provides an anti-freezing water-resisting layer and a roadbed. The anti-freezing water-resisting layer is arranged at the bottom of the roadbed, and comprises at least one layer of anti-seepage film and non-woven geotextile, wherein the anti-seepage film is used for blocking the migration of water in frozen earth to the roadbed direction; and the non-woven geotextile is arranged ontwo side surfaces of the anti-seepage film and used for coating the anti-seepage film, so that the anti-seepage film can be isolated from a roadbed filler or the frozen earth and protected against relatively large deformation caused by load. The anti-freezing water-resisting layer provided by the invention is arranged at the bottom of the roadbed, and serves as a partition between the roadbed andthe frozen earth in a plateau seasonally-frozen zone; and due to the own anti-seepage function of the anti-freezing water-resisting layer, the migration of the water in the frozen earth to the roadbed can be blocked, the water content of the roadbed fill in the roadbed can be stabilized, and the roadbed frost-heaving or frost-boiling caused by the roadbed fill in a freezing and thawing environment can be avoided.

Description

technical field [0001] The application relates to the technical field of roadbed structures, in particular to an antifreeze water-proof layer and a roadbed. Background technique [0002] The subgrade is the foundation of the road surface and is a geotechnical structure formed after excavation or filling. The subgrade can provide the necessary conditions for pavement laying and vehicle operation, and bear the load of the road surface and vehicles or the road surface and traffic, and at the same time transmit and spread the traffic load to the depth of the subgrade. [0003] At present, subgrades are usually constructed by means of low-fill and shallow excavation such as digging and rolling, excavation and replacement, and adding gravel blind ditches to form low-fill and shallow-cut subgrades. The subgrade filler in the low-fill and shallow-cut subgrade is of good quality, which can increase the bearing capacity of the subgrade and curb the adverse effects of groundwater on t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E01C3/00E01C3/06

CPCE01C3/00E01C3/06

Inventor 李茜杜晓宇于洪国曹晓勇段鑫明扎拉吴曼

Owner CHINA COMM NORTH ROAD & BRIDGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com