Method for treating subgrade of highway in frozen soil region

A processing method and expressway technology, applied in the field of road engineering and geotechnical engineering, can solve the problems of highway durability and stability threats, subsidence, subgrade frost heave, etc., so as to improve the stability and durability of the subgrade and enhance the service performance. , to avoid the effects of frost heave and thawing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

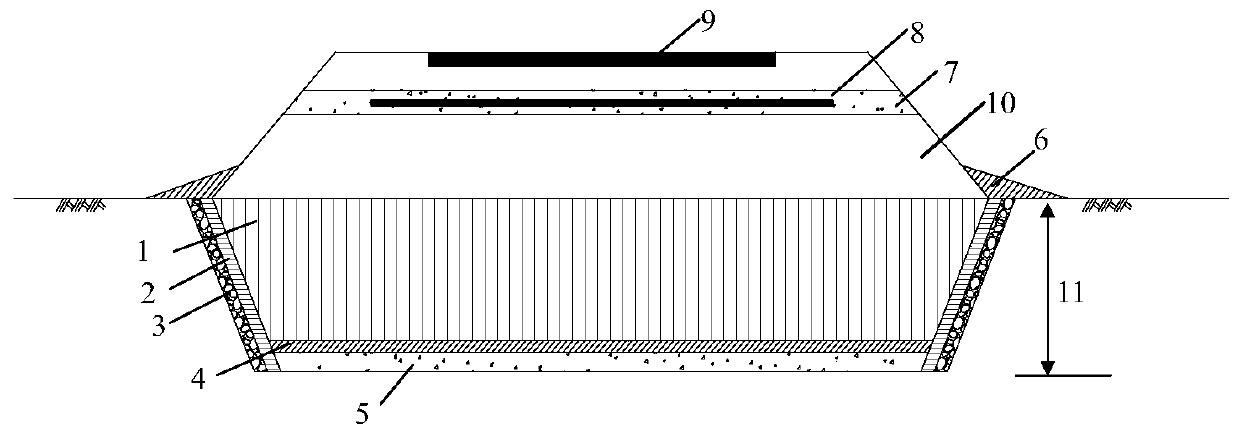

[0028] A method for treating highway subgrades in frozen soil in cold regions, such as figure 1 shown. It is characterized in that it comprises the following steps:

[0029] a. Firstly, according to the subgrade survey report, determine the subgrade frozen depth line in cold regions; select the appropriate method according to the freezing depth and site conditions, choose winter construction, and preferentially use the electric heating method or steam method to pre-thaw the subgrade frozen soil above the depth line 11 , that is, all frozen soil in the excavation area from the coarse grain layer 5 to the surface.

[0030] b. Use an excavator to excavate all the frozen soil in the thawing area, and use an earth truck to transport the thawed soil to the storage place. The corresponding excavation slope is 1:0.5; the excavation work should be continuously excavated day and night after the frozen soil thaws Thaw the soil to avoid refreezing.

[0031] c. lay the bottom coarse gra...

Embodiment 2

[0036] A method for treating highway subgrades in frozen soil in cold regions, such as figure 1 shown. It is characterized in that it comprises the following steps:

[0037] a. Firstly, according to the subgrade survey report, determine the subgrade frozen depth line in cold regions; select the appropriate method according to the freezing depth and site conditions, choose winter construction, and preferentially use the electric heating method or steam method to pre-thaw the subgrade frozen soil above the depth line 11 , that is, all frozen soil in the excavation area from the coarse grain layer 5 to the surface.

[0038] b. Use an excavator to excavate all the frozen soil in the thawing area, and use an earth truck to transport the thawed soil to the storage place. The corresponding excavation slope is 1:0.75; the excavation work should be continuously excavated day and night after the frozen soil thaws Thaw the soil to avoid refreezing.

[0039] c. lay the bottom coarse gr...

Embodiment 3

[0044] A method for treating highway subgrades in frozen soil in cold regions, such as figure 1 shown. It is characterized in that it comprises the following steps:

[0045] a. Firstly, according to the subgrade survey report, determine the subgrade frozen depth line in cold regions; select the appropriate method according to the freezing depth and site conditions, choose winter construction, and preferentially use the electric heating method or steam method to pre-thaw the subgrade frozen soil above the depth line 11 , that is, all frozen soil in the excavation area from the coarse grain layer 5 to the surface.

[0046] b. Use an excavator to excavate all the frozen soil in the thawing area, and use an earth truck to transport the thawed soil to the storage place. The corresponding excavation slope is 1:1; the excavation work should be continuously excavated day and night after the frozen soil thaws Thaw the soil so it doesn't freeze again.

[0047] c. lay the bottom coars...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com