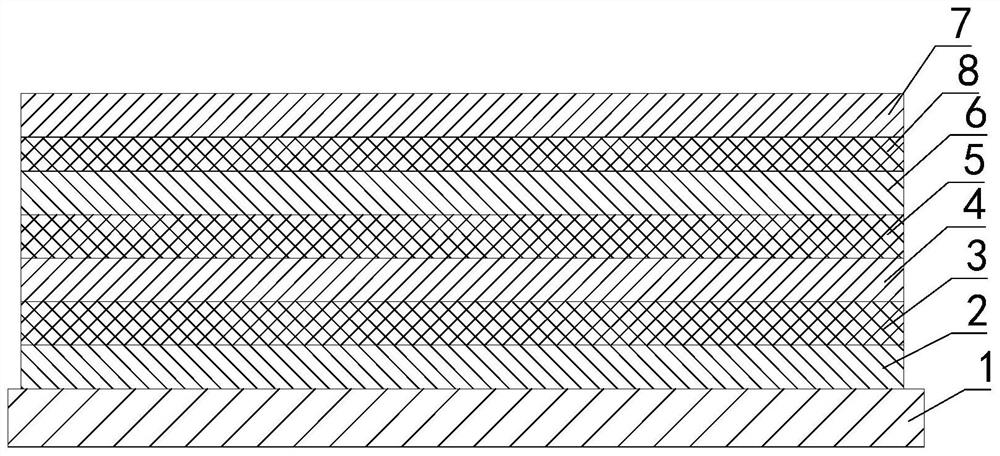

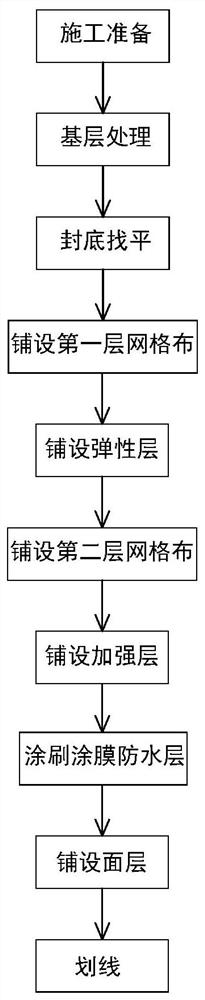

Two-cloth-two-coating reinforced plastic track and construction method

A technology of plastic runway and construction method, applied in the direction of roads, roads, buildings, etc., can solve the problems of easy rupture of elastic layer and reinforcement layer, short service life of runway, health hazards, etc., to improve the overall quality and service life, The effect of reducing the probability of safety accidents and speeding up the construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1: A certain school project project completed by the construction method of the present invention has a building area of 9451.1㎡, and an outdoor plastic runway area of about 2798㎡.

[0063] In terms of labor, the traditional plastic method requires 5 times of brushing for the elastic layer and the reinforcing layer, but through the construction method of the two-cloth and two-coating reinforced plastic runway of the present invention, the elastic layer and the reinforcing layer only need 3 times each. Compared with the workers, the workload of painting twice has been reduced; taking this project as an example, the area of the outdoor plastic runway is about 2798㎡; traditional craft: 2798㎡÷10㎡ / working day=279.8 working days, 10 workers on site, need 28 New technology: 2798㎡÷16㎡ / manday = 174.8 mandays, 10 people on site, 18 days to complete; 10 mandays for laying grid cloth; save labor costs by about 10×(28-18) ×480 yuan / day-10×480=43200 yuan.

[0064] I...

Embodiment 2

[0067] Embodiment 2: A certain school project project completed by the construction method of the present invention has a building area of 48182.1㎡, and an outdoor plastic runway area of about 6880㎡.

[0068] In terms of labor, in the traditional plastic method, the elastic layer and the reinforced layer each need to be painted 5 times, while the construction method of the two-cloth and two-coated reinforced plastic track of the present invention requires only 3 times each for the elastic layer and the reinforced layer. The workload of painting twice has been reduced; taking this project as an example, the area of the outdoor plastic runway is about 6880㎡; traditional craft: 6880㎡÷10㎡ / manday = 688 mandays, 17 people are employed on site, and it takes 41 days to complete the project ; New process: 6880㎡÷16㎡ / working day = 430 working days, 17 people are employed on site, and it takes 26 days to complete the work; 20 working days are required to lay the grid cloth; about 10 ...

Embodiment 3

[0072] Embodiment 3: A primary school project project completed by using the construction method of the present invention has a building area of 32678.44㎡, and an outdoor plastic runway area of about 7234㎡.

[0073] In terms of labor, in the traditional plastic method, the elastic layer and the reinforced layer each need to be painted 5 times, while the construction method of the two-cloth and two-coated reinforced plastic track of the present invention requires only 3 times each for the elastic layer and the reinforced layer. Reduces the workload of two coats of painting. Taking this project as an example, the area of the outdoor plastic runway is about 7234㎡. Traditional craft: 7234㎡÷10㎡ / manday=723.4 mandays, with 20 on-site workers, it takes 37 days to complete; new craft: 7234㎡÷16㎡ / manday=452.1 mandays, with 20 on-site workers, it takes 23 days Completion; laying grid cloth takes 22 working days; about saving labor costs 10×(37-23)×480 yuan / day-22×480=123840 yuan. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com