Composite geomembrane for high-speed railway roadbed

A composite geomembrane, high-speed railway technology, applied in roads, buildings, tracks, etc., can solve problems such as affecting the stability and service life of railway subgrades, difficult to adapt to the complex environment along the railway, easy to be blocked by gravel and lateral drainage capacity, etc. Achieve excellent lateral drainage performance, excellent acid and alkali resistance, and prevent the phenomenon of turning mud and slurry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

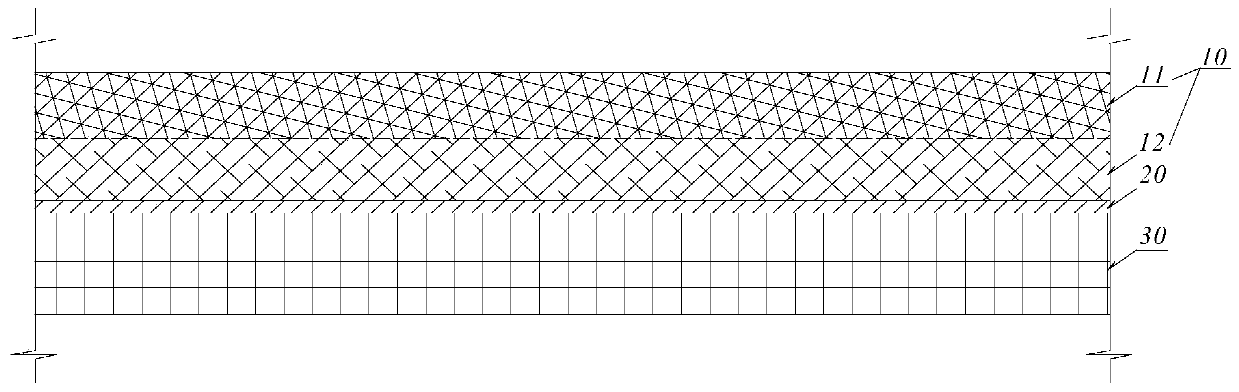

[0019] The weight of the upper polypropylene filament composite geotextile 10 is 150g / m 2 , including an upper layer of fine polypropylene filament geotextile 11 and a lower layer of coarse polypropylene filament geotextile 12. Wherein the grammage of upper fine polypropylene filament geotextile 11 is 50g / m 2 , The fiber fineness is 5D, and the weight of the lower coarse polypropylene filament geotextile 12 is 100g / m 2 , The fiber fineness is 11D. The upper layer of fine polypropylene filament geotextile 11 and the lower layer of coarse polypropylene filament geotextile 12 are produced by a spunbond production line device, and then stacked together and consolidated into one body through a needle punching process. The average longitudinal and transverse tensile strength of the upper polypropylene filament composite geotextile 10 is 9.5kN / m, the tear strength is 523.6N, the CBR bursting strength is 1870N, and the in-plane water permeability is 7.8l / m.h.

[0020] The polyethyl...

Embodiment 2

[0024] The weight of the upper polypropylene filament composite geotextile 10 is 200g / m 2 , including an upper layer of fine polypropylene filament geotextile 11 and a lower layer of coarse polypropylene filament geotextile 12. Wherein the grammage of upper fine polypropylene filament geotextile 11 is 50g / m 2 , The fiber fineness is 5D, and the weight of the lower coarse polypropylene filament geotextile 12 is 150g / m 2 , The fiber fineness is 11D. The upper layer of fine polypropylene filament geotextile 11 and the lower layer of coarse polypropylene filament geotextile 12 are produced by a spunbond production line device, and then stacked together and consolidated into one body through a needle punching process. The average longitudinal and transverse tensile strength of the upper polypropylene filament composite geotextile 10 is 12.1kN / m, the tear strength is 673N, the CBR bursting strength is 2398N, and the in-plane water permeability is 11.8l / m.h.

[0025] The polyethyl...

Embodiment 3

[0029] The weight of the upper polypropylene filament composite geotextile 10 is 200g / m 2 , including an upper layer of fine polypropylene filament geotextile 11 and a lower layer of coarse polypropylene filament geotextile 12. Wherein the grammage of upper fine polypropylene filament geotextile 11 is 50g / m 2 , The fiber fineness is 5D, and the weight of the lower coarse polypropylene filament geotextile 12 is 150g / m 2, The fiber fineness is 11D. The upper layer of fine polypropylene filament geotextile 11 and the lower layer of coarse polypropylene filament geotextile 12 are produced by a spunbond production line device, and then stacked together and consolidated into one body through a needle punching process. The average longitudinal and transverse tensile strength of the upper polypropylene filament composite geotextile 10 is 12.1kN / m, the tear strength is 673N, the CBR bursting strength is 2398N, and the in-plane water permeability is 11.8l / m.h.

[0030] The polyethyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com