Reverse drainage system capable of reducing water pressure at bottom of tunnel

A technology of drainage system and bottom water, applied in drainage, safety devices, mining equipment and other directions, can solve the problems of short time for renovating and constructing skylights, reduced overall elasticity, and high train density, avoiding the phenomenon of mud and mud, and meeting durability. requirements, the effect of reducing water pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

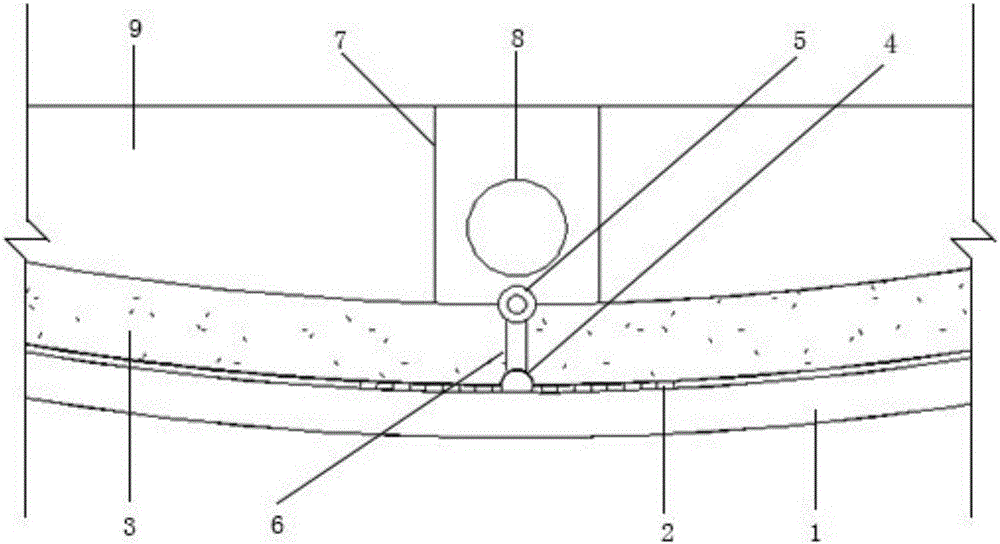

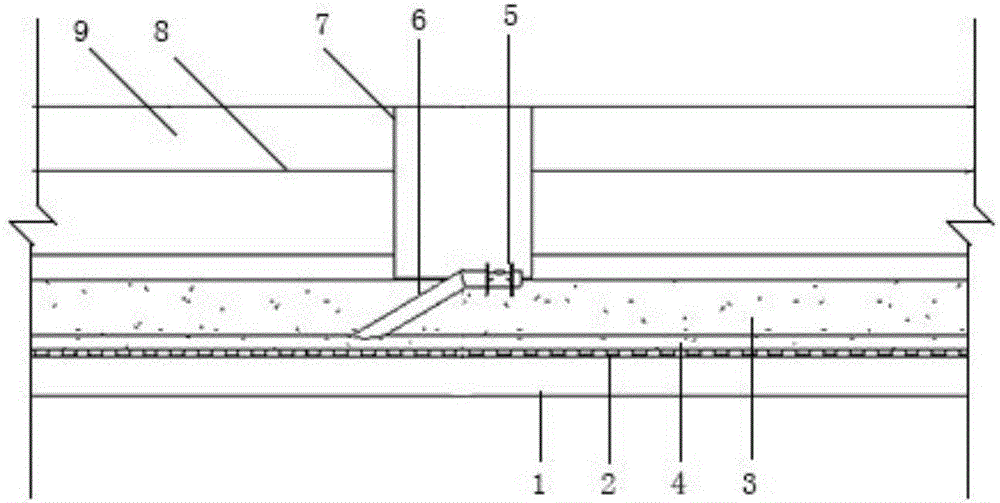

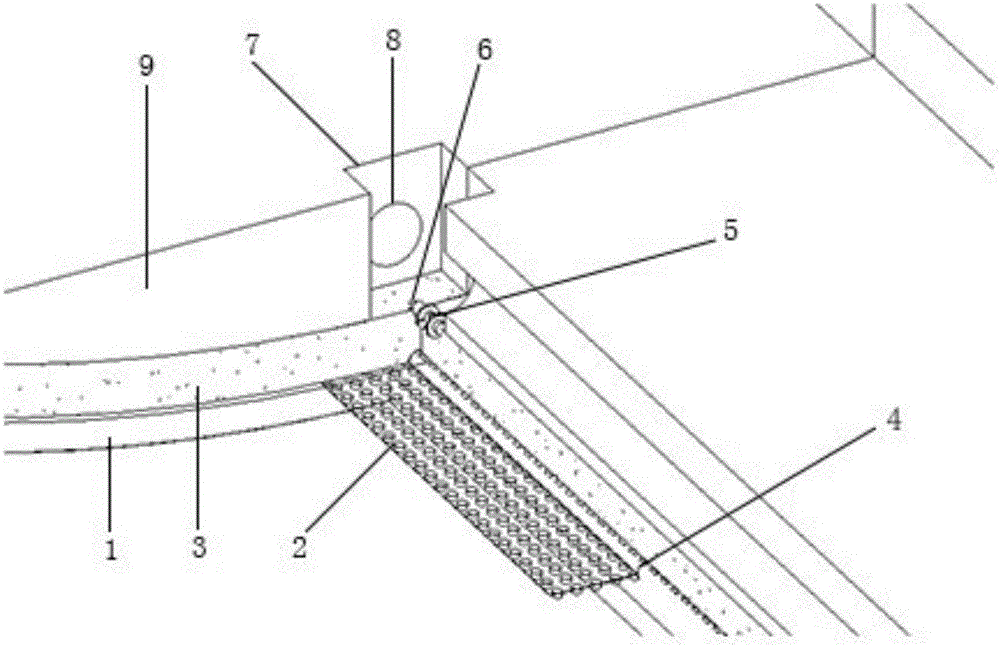

[0021] Such as Figure 1-3 As shown, a reverse drainage system to reduce the water pressure at the bottom of the tunnel, the implementation process of this step is as follows:

[0022] Step 1. Install a horizontal waterproof and drainage board 2 at the construction joint of the inverted arch between the bottom primary support 1 and the inverted arch lining 3. The horizontal waterproof and drainage board 2 is connected to the longitudinal water collection system at the bottom of the tunnel, and is located in the middle and upper part of the vertical water collection system. A round pipe 4 with a diameter of 150-200 mm is provided.

[0023] Step 2: Install the oblique drainage pipe 6 at the position of the inspection well and connect the circular pipe 4 along the 30° oblique direction of the drainage longitudinal slope of the tunnel, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com