Efficient dephosphorization method of combined blown converter

A converter and high-efficiency technology, applied in the direction of manufacturing converters and improving process efficiency, can solve problems such as poor production organization, explosive splashing, and easy splashing, so as to improve the dephosphorization effect, improve production efficiency, The effect of shortening the smelting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The converter is a 150-ton top-bottom combined blowing converter.

[0050] A method for high-efficiency dephosphorization of a combined blowing converter, comprising the following steps:

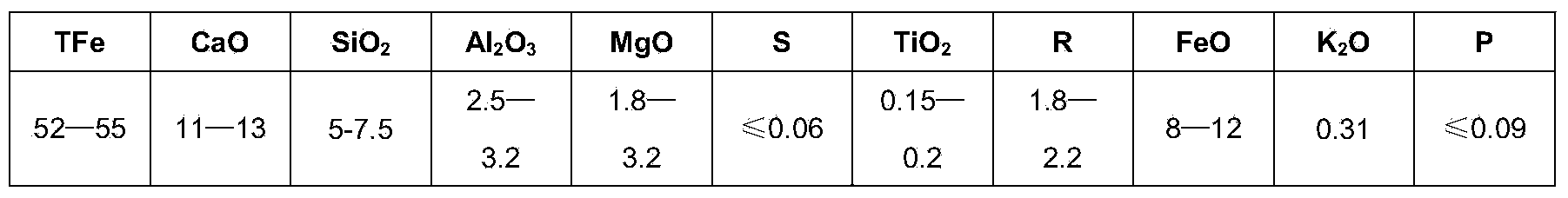

[0051] Prepare slag-making materials, calculated per ton of molten steel: active lime, dolomite, sinter and slag adjustment agent;

[0052] The added amount of active lime is 46kg / t;

[0053] The dolomite addition is 15kg / t;

[0054] The sinter addition amount is 30kg / t;

[0055] The slag adjusting agent is granular steel, and the addition amount of granular steel is 5kg / t; wherein the main component of granular steel is iron-containing oxide, which is obtained by screening and magnetic separation of converter splash slag, and the granular steel contains iron oxide The rate is 27-30%;

[0056] The concrete steps of the method for the efficient dephosphorization of the reblown converter are as follows:

[0057] (1) According to the existing technology, according to the silicon conte...

Embodiment 2

[0081] According to the method of a kind of complex blowing converter high-efficiency dephosphorization described in Example 1, the difference is that in step (4) the position of the oxygen-reducing lance is fixed to 1550mm, all the remaining active lime is added, and the opening of the oxygen lance nozzle blows oxygen The pressure is controlled at 0.83-0.85 Mpa; after blowing for 7 minutes, the remaining sinter and granular steel will be added to molten iron in batches at intervals: the amount of sinter and granular steel added in each batch is 4.0kg / t and 3.2kg / t respectively , feeding interval 40 ~ 60s.

Embodiment 3

[0083] The converter is a 120-ton top-bottom combined blowing converter.

[0084] A method for high-efficiency dephosphorization of a combined blowing converter, comprising the following steps:

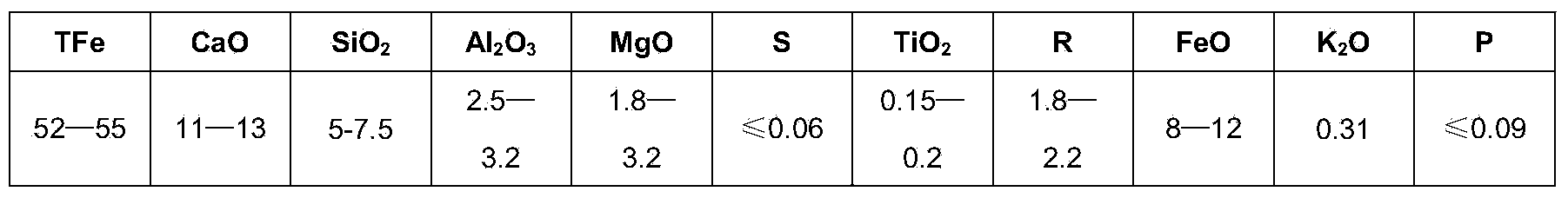

[0085] Prepare slag-making materials, calculated per ton of molten steel: active lime, dolomite, sinter and slag adjustment agent;

[0086] The active lime addition 55kg / t;

[0087] The dolomite addition is 17kg / t;

[0088] The sinter addition is 40kg / t;

[0089] The slag adjusting agent is granular steel, and the addition amount of granular steel is 10kg / t; wherein the main component of granular steel is iron-containing oxide, which is obtained by screening and magnetic separation of converter splash slag, and the granular steel contains iron oxide The rate is 27-30%;

[0090] The concrete steps of the method for the efficient dephosphorization of the reblown converter are as follows:

[0091] (1) According to the existing technology, according to the silicon content in the molt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com