Dephosphorization method of phosphorus-containing iron ore

A technology for iron ore and dephosphorization, applied in the direction of improving process efficiency, can solve problems such as poor dephosphorization effect, and achieve the effect of low dephosphorization cost and good dephosphorization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

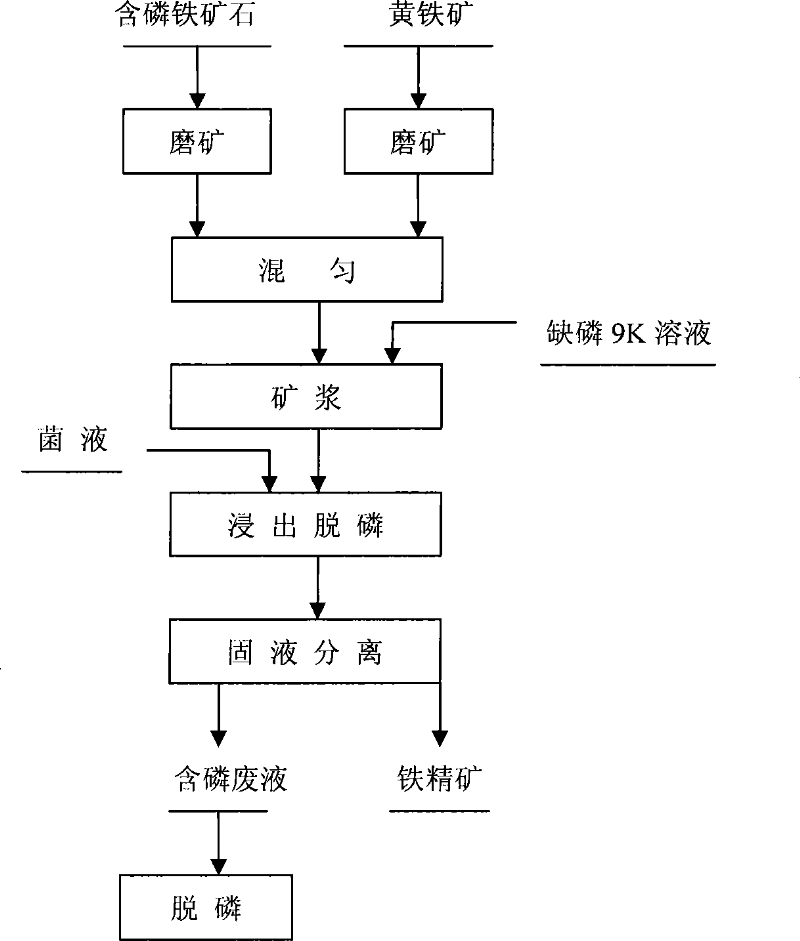

[0013] Embodiment 1, referring to the accompanying drawings, the phosphorus-containing iron ore of 1.12% is crushed to a particle size of less than 0.074mm, and 10% of pyrite with a particle size of less than 0.074mm is added to the phosphorus-containing iron ore by mass percentage. The 9K culture medium solution adjusts the mass concentration of the pulp to 10%, and adds 5% of Thiobacillus ferrooxidans (T.f bacteria) bacteria solution according to the mass percentage. The initial pH of the pulp is 2.2. Under the condition of leaching for 35 days, the dephosphorization rate reaches 68.81%. ; When the pyrite content increased to 20%, the dephosphorization rate was 78.84%.

Embodiment 2

[0014] Embodiment 2, referring to the accompanying drawings, the phosphorus-containing iron ore of 1.12% is crushed to a particle size of less than 0.074mm, and 20% of pyrite with a particle size of less than 0.074mm is added to the phosphorus-containing iron ore by mass percentage. 9K medium solution adjusts the mass concentration of the pulp to 15%, and adds 5% T.f bacteria liquid according to the mass percentage. When the initial pulp pH is 1.7 and 2.0, the dephosphorization rate reaches 86.68% and 86.63 respectively under the condition of leaching for 45 days. %; when the pH is lower than 1.5, it is difficult for bacteria to survive; when the pH is 3.5, the dephosphorization rate drops to 78%.

Embodiment 3

[0015] Embodiment 3, referring to the accompanying drawings, the phosphorus-containing iron ore of 1.12% is crushed to a particle size of less than 0.074mm, and 20% of the pyrite with a particle size of less than 0.074mm is added to the phosphorus-containing iron ore by mass percentage. 9K culture medium solution adjusts the pulp mass concentration to 20%, the initial pulp pH is 2.2, and under the conditions of leaching for 45 days, when the inoculation amount of T.f bacteria solution increases from 2% to 5% by mass percentage, the dephosphorization rate increases from 67.70 % increased to 78.84%; and when the inoculation amount of T.f bacteria solution increased from 5% to 10%, the ore dephosphorization rate only increased from 78.84% to 79.95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com