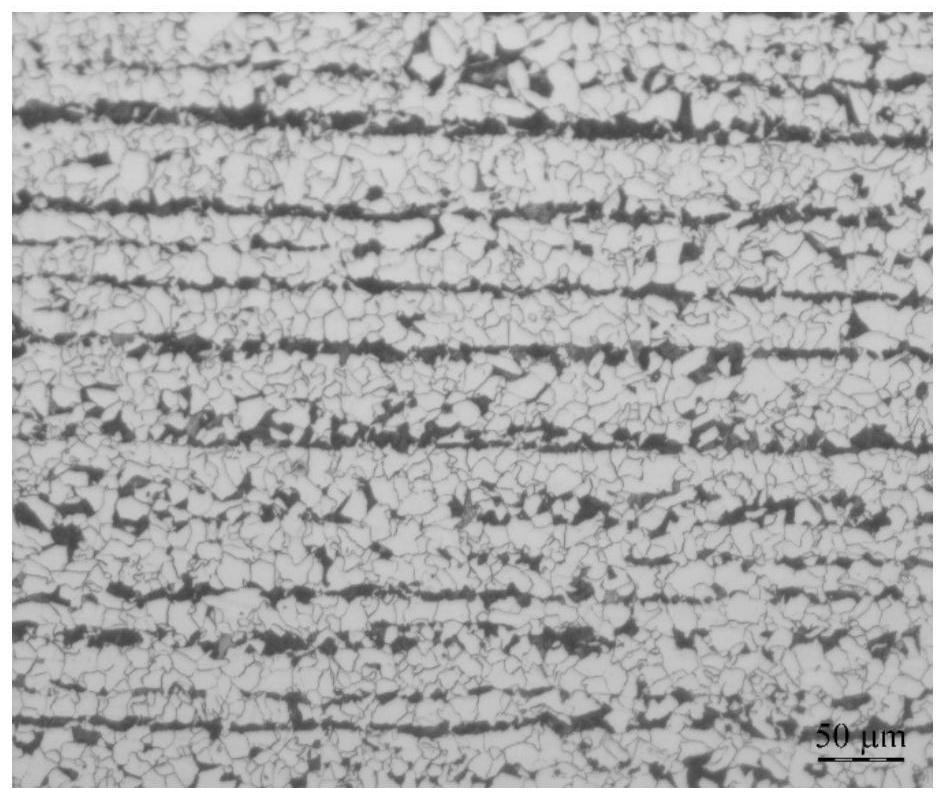

A kind of yield strength 420mpa grade hot-rolled low-temperature resistant H-section steel and preparation method thereof

A yield strength, H-beam technology, applied in the field of metallurgy, can solve the problems of low dephosphorization rate of single converter, large molten iron temperature drop, large equipment investment, etc., achieve good dephosphorization kinetic conditions, improve low temperature toughness, and structure stability. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be described below with reference to specific examples. It should be pointed out that the embodiments are only used to further illustrate the present invention, and do not limit the protection scope of the present invention. Non-essential modifications and adjustments made by others according to the present invention still belong to the protection scope of the present invention.

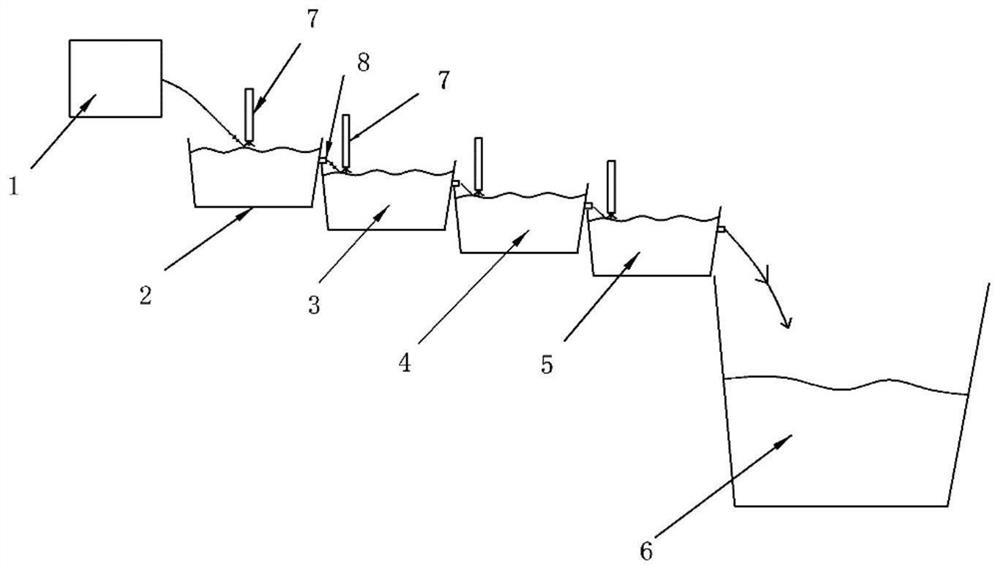

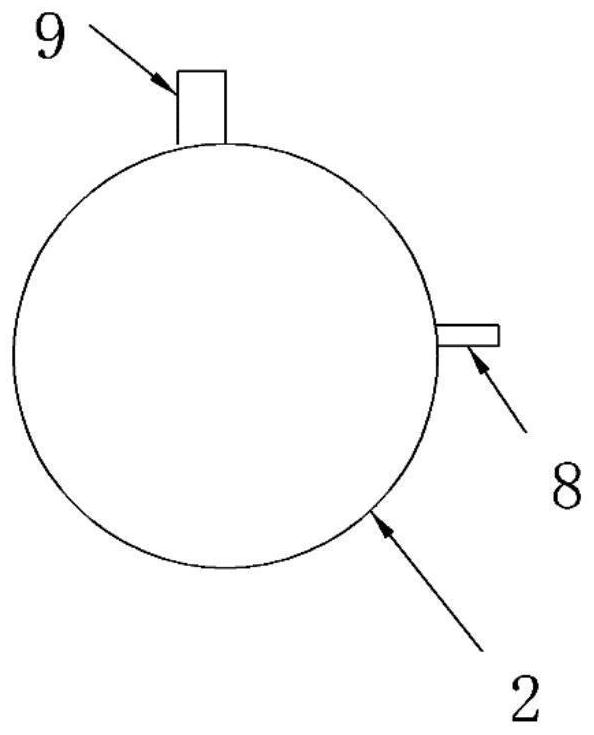

[0073] The continuous casting slabs in the following examples are all prepared according to the following technological process: according to the set chemical composition range (Table 1), with blast furnace molten iron as raw material, dephosphorization, KR dephosphorization, converter smelting in blast furnace iron casting process are carried out. , refining, adjust the content of C, Si, Mn, S, P, etc. and carry out microalloying. After the composition reaches the target value, perform continuous casting, direct heating or soaking of the slab. The preparation steps ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com