Aluminum-titanium acidic sintered flux and preparation method thereof

A sintered flux and acidic technology, applied in welding equipment, manufacturing tools, welding media, etc., can solve problems such as unstable arc combustion, high fluorine ionization potential, and affecting welding quality, and achieve simple manufacturing methods, uniform components, and welding Excellent quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

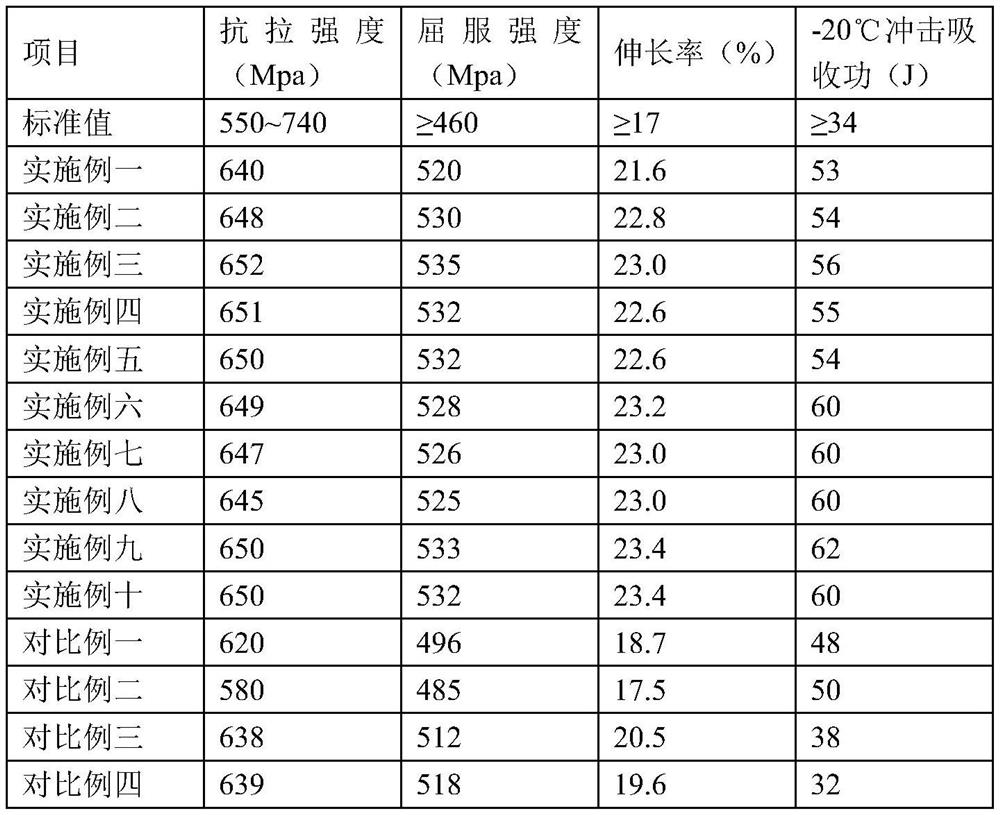

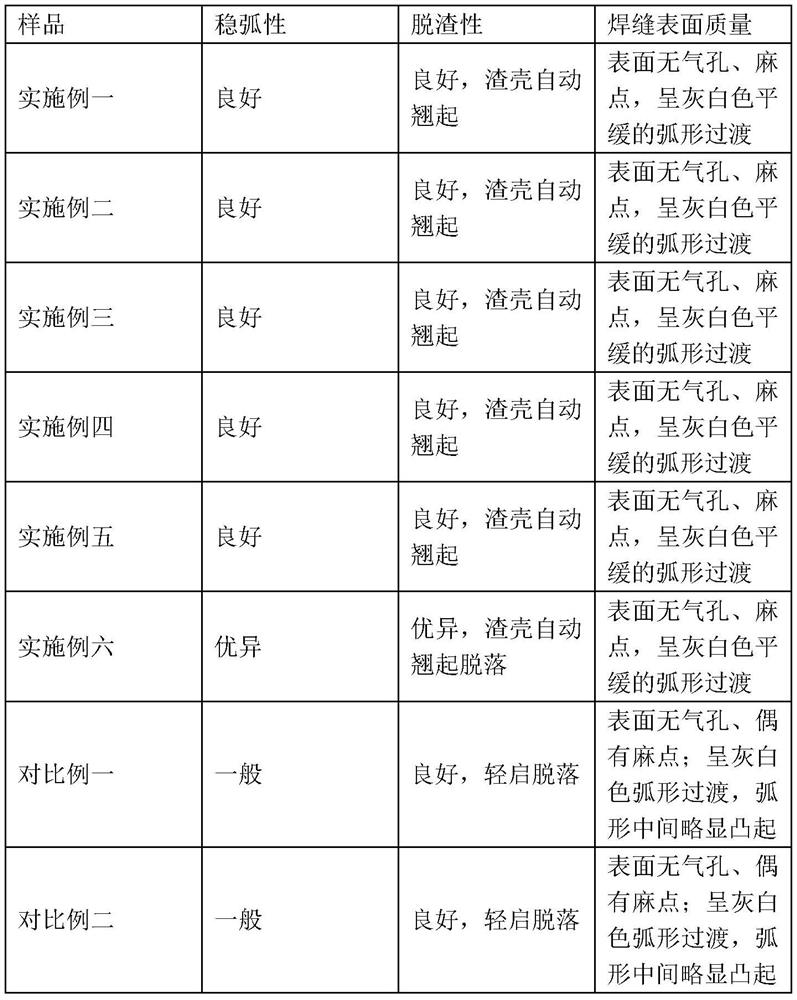

Examples

preparation example 1

[0045] A kind of alkalinity fusing point regulator, adopts following steps to prepare:

[0046] (1) Batching: weigh the following components by weight percentage, dead burnt magnesia 55%, wollastonite powder 30%, mass concentration are 50% potassium carbonate solution 5% and potassium feldspar 10%;

[0047] (2) under stirring state, potassium carbonate solution is sprayed on the surface of dead burnt magnesia with spray state;

[0048] (3) Add wollastonite powder and potassium feldspar, stir to obtain a blend;

[0049] (4) The blend is put into a granulator, and the water mist spray flow rate is 0.25L / min, and granulated to obtain spherical particles;

[0050] (5) Spherical particles are calcined at a high temperature of 750° C. until the water content is lower than 1%, to prepare an alkalinity melting point regulator.

preparation example 2

[0052] An alkalinity melting point regulator, the difference from the raw material preparation example 1 is that the formula content is different, and the following components are weighed in percentages by weight: 60% of dead-burned magnesia, 25% of wollastonite powder, 7% of potassium carbonate solution and Potassium feldspar 8%.

preparation example 3

[0054] An alkalinity melting point regulator, the difference from the raw material preparation example 1 is that the formula content is different, and the following components are weighed in percentages by weight: 70% of dead-burned magnesia, 20% of wollastonite powder, 5% of potassium carbonate solution and Potassium feldspar 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com