EPR(ethylene propylene rubber)/ZnO nano composite material synthesized in situ and preparation method thereof

A nano-composite material and in-situ synthesis technology, applied in the field of nano-composite materials and its preparation, can solve the problems of insignificant reinforcing effect, complex dispersion process, and inability to directly add, etc., achieve excellent reinforcing effect, simple preparation process, evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

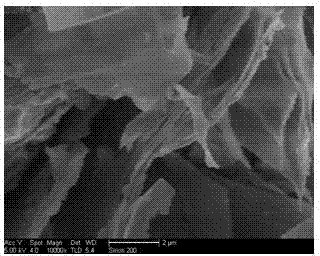

[0020] Weigh 0.2 mol of zinc acetate and 0.2 mol of hexamethylenetetramine respectively, place them in 200ml of deionized water, ultrasonically dissolve, mix and dilute to 1L, place in a constant temperature water tank at 60°C, react for 2 hours, pump After filtration, washing, and drying at 60°C, a white solid was obtained, which was observed under a scanning electron microscope (SEM) as a lamellar structure, such as figure 1 shown.

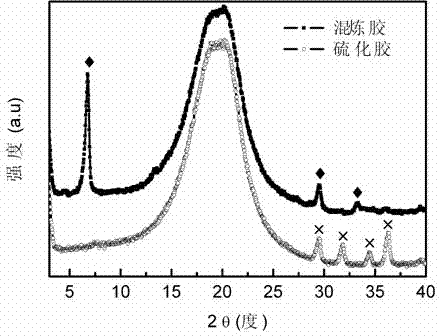

[0021] Then add 100g of ethylene-propylene rubber, 1g of layered zinc hydroxide and 2g of dicumyl peroxide into the open mill in turn, and knead at 50°C for 10min to obtain EPR / Zn(OH) 2 Composite mixed rubber; finally put the mixed rubber on a flat vulcanizing machine and vulcanize at 150 °C for 10 minutes to obtain EPR / ZnO nanocomposites. The phase transition process during the vulcanization process is as follows figure 2 As shown, the dispersion effect and mechanical properties are as image 3 and Figure 4 shown.

Embodiment 2

[0023] Weigh 0.2 mol of zinc acetate and 0.2 mol of hexamethylenetetramine respectively, place them in 200ml of deionized water, ultrasonically dissolve, mix and dilute to 1L, place in a constant temperature water tank at 65°C, react for 1 hour, pump After filtration, washing, and drying at 60°C, a white solid was obtained, which was observed under a scanning electron microscope (SEM) as a lamellar structure, such as figure 1 shown.

[0024] Then 100g of ethylene-propylene rubber, 2g of layered zinc hydroxide and 2g of dicumyl peroxide were sequentially added into the open mill, and mixed at 50°C for 10min to obtain EPR / Zn(OH) 2 Composite mixed rubber; finally put the mixed rubber on a flat vulcanizing machine and vulcanize at 150 °C for 10 minutes to obtain EPR / ZnO nanocomposites. The phase transition process during the vulcanization process is as follows figure 2 As shown, the dispersion effect and mechanical properties are as image 3 and Figure 4 shown.

Embodiment 3

[0026] Weigh 0.2 mol of zinc acetate and 0.2 mol of hexamethylenetetramine respectively, place them in 200ml of deionized water, ultrasonically dissolve, mix and dilute to 1L, place in a constant temperature water tank at 60°C, react for 2 hours, pump After filtration, washing, and drying at 60°C, a white solid was obtained, which was observed under a scanning electron microscope (SEM) as a lamellar structure, such as figure 1 shown.

[0027] Then 100g of ethylene-propylene rubber, 4g of layered zinc hydroxide and 2g of dicumyl peroxide were sequentially added into the open mill, and mixed at 50°C for 10min to obtain EPR / Zn(OH) 2 Composite mixed rubber; finally put the mixed rubber on a flat vulcanizing machine and vulcanize at 150 °C for 10 minutes to obtain EPR / ZnO nanocomposites. The phase transition process during the vulcanization process is as follows figure 2 As shown, the dispersion effect and mechanical properties are as image 3 and Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com