Method for preparing nylon 6 civil chips with uniform dyeing properties

A technology of uniform dyeing and nylon, applied in the manufacture of rayon, single-component polyamide rayon, chemical characteristics of fibers, etc., can solve problems such as uneven dyeing, and achieve easy dyeing, high color fastness, and good permeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

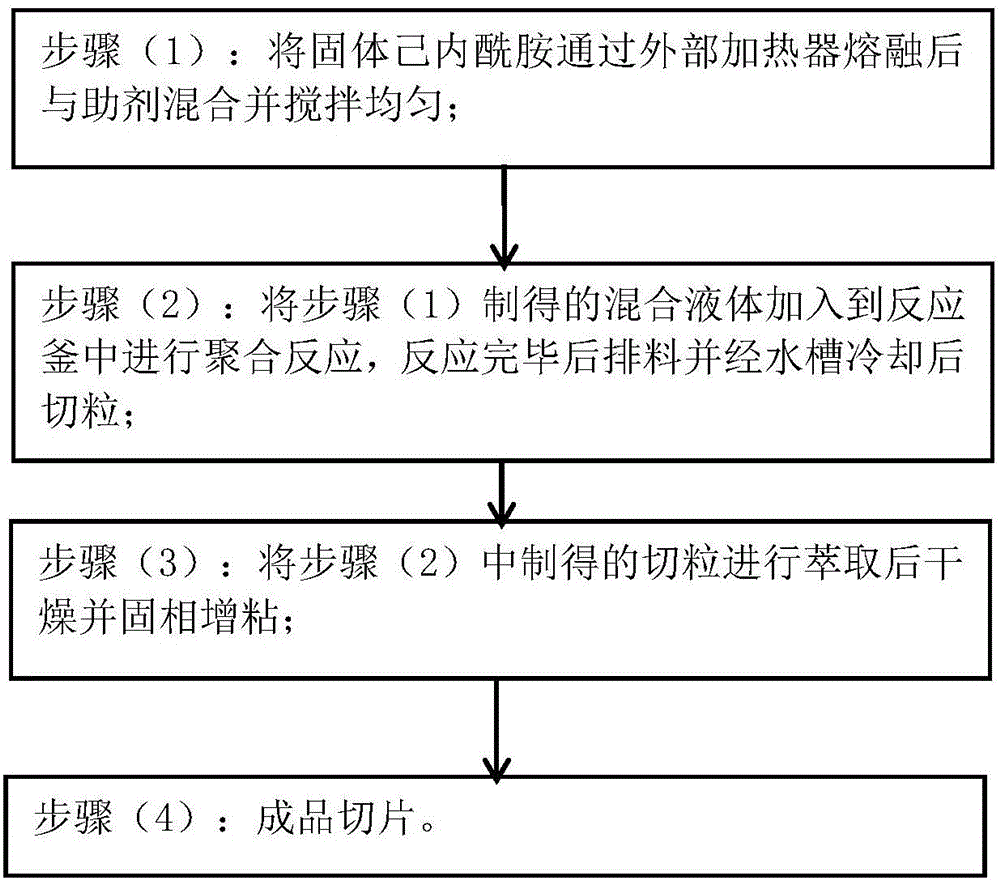

[0027] The invention discloses a preparation method of uniformly dyeable nylon 6 civil slices, such as figure 1 shown, including the following steps:

[0028] Step (1): Melt the solid caprolactam through an external heater, mix it with the auxiliary agent and stir evenly; preferably, it also includes a plant fiber dissolving solution, and the weight part of the plant fiber dissolving solution in the mixed solution is 10-20, so The weight part of the auxiliary agent is 5-10, and the weight part of the caprolactam solution is 70-85. Wherein the preparation of plant fiber dissolving liquid: mix the plant fiber that is 90~100 parts by weight with the dimethyl sulfoxide that is 2~10 parts by weight, after stirring evenly, let stand for 2~3 hours, let plant fiber and dimethyl sulfoxide Fully react, so that the plant fiber is completely dissolved. It is mixed with other mixed liquids to make nylon 6. When the nylon 6 is used to prepare spinning materials, the plant fiber solution w...

Embodiment 1

[0033] A preparation method for uniformly dyeable nylon 6 civil slices, comprising the following steps:

[0034]Step (1): The solid caprolactam is melted by an external heater and mixed with the plant fiber dissolving liquid and the auxiliary agent and stirred evenly; the weight part of the plant fiber dissolving liquid in the mixed liquid is 10, and the weight part of the auxiliary agent is 5 , the weight portion of the caprolactam solution is 85. Wherein the preparation of the plant fiber dissolving solution: mix 90 parts by weight of plant fibers and 10 parts by weight of dimethyl sulfoxide, stir evenly and then let stand for 3 hours. The plant fibers include kapok fiber, abaca fiber and flax fiber, and the weight ratio of the kapok fiber, abaca fiber and flax fiber is 1:1:1. The auxiliary agent includes a matting agent, an initiator and an anti-ultraviolet solvent, and the weight ratio of the matting agent, the initiator and the anti-ultraviolet solvent is 2:2:1. The ant...

Embodiment 2

[0039] A preparation method for uniformly dyeable nylon 6 civil slices, comprising the following steps:

[0040] Step (1): The solid caprolactam is melted by an external heater, mixed with the plant fiber dissolving liquid and the auxiliary agent and stirred evenly; the weight part of the plant fiber dissolving liquid in the mixed liquid is 12, and the weight part of the auxiliary agent is 7 , the weight portion of the caprolactam solution is 71. Wherein the preparation of the plant fiber dissolving solution: mix 95 parts by weight of plant fiber and 5 parts by weight of dimethyl sulfoxide, stir evenly and let stand for 2 hours. The plant fibers include kapok fiber, abaca fiber and flax fiber, and the weight ratio of the kapok fiber, abaca fiber and flax fiber is 1:1:1. The auxiliary agent includes a matting agent, an initiator and an anti-ultraviolet solvent, and the weight ratio of the matting agent, the initiator and the anti-ultraviolet solvent is 2:2:1. Wherein the anti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com