Dephosphorization method for oolitic high phosphorus iron ore

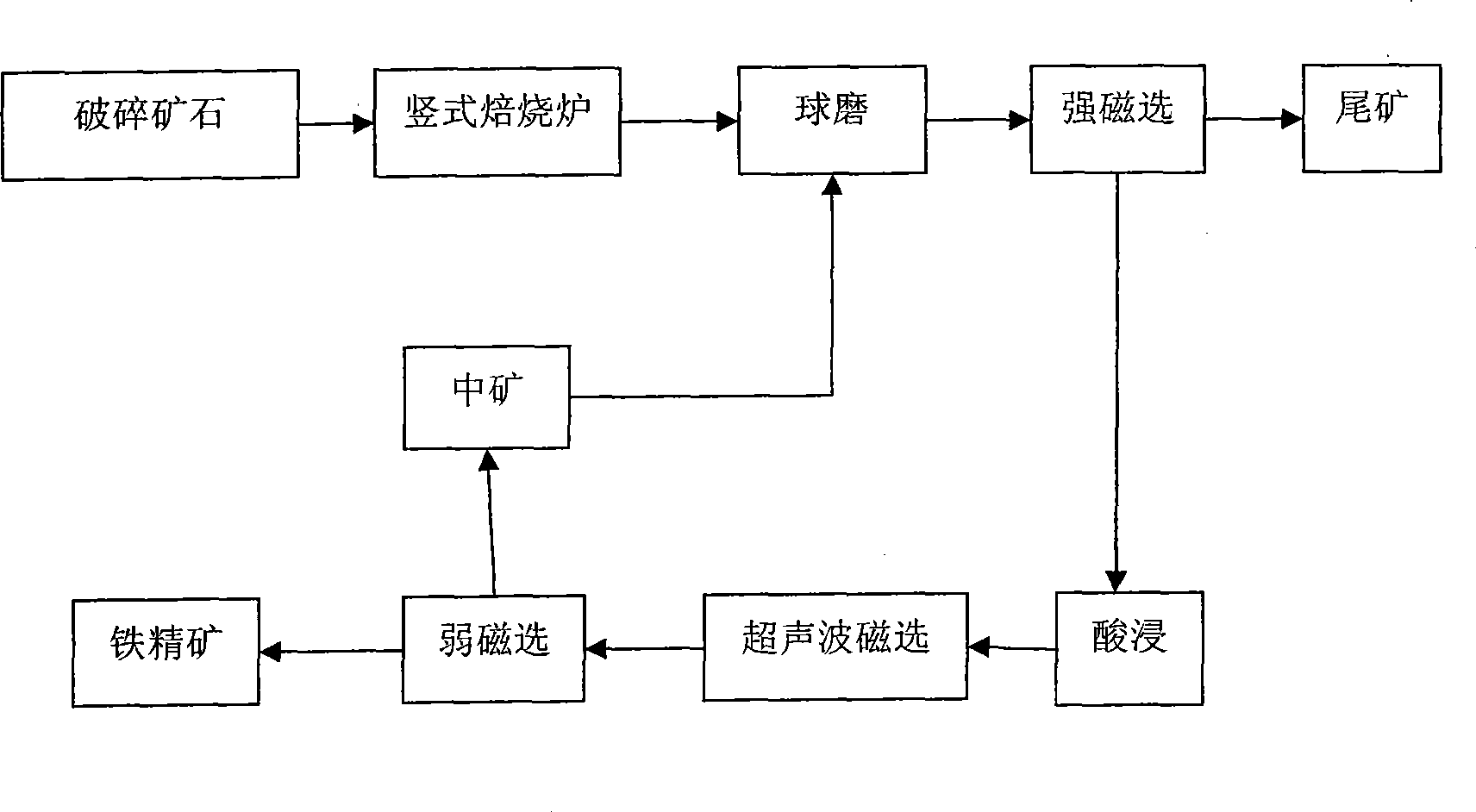

A high-phosphorus iron ore and oolitic technology is applied in the field of dephosphorization of high-phosphorus iron ore, which can solve the problems of high cost and poor dephosphorization effect, and achieve the effects of low production cost, convenient operation and excellent dephosphorization effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The product of this experiment is an industrial experiment product. Test site: Huaguoqing High Phosphorus Iron Ore Matching Plant, Wuding, Yunnan, main parameters: use a crusher to crush the raw ore to below 30mm; use a 15m 3 Shaft furnace, roasting temperature 700°C, coal mine ratio 1:25, roasting time 20 minutes. Grinding time is 5 minutes, the fineness of ore powder is 0.045mm to reach 75%, strong magnetic separation adopts 4000 gauss; acid leaching: use 8% dilute nitric acid solution, acid leaching time: 3 hours, ultrasonic cleaning: 20,000 Hz frequency, cleaning Time: 15 minutes. After weak magnetic separation, a good phosphorus removal effect is achieved, and the iron grade reaches above 58%.

Embodiment 2

[0015] Oolitic high-phosphorus iron ore in Wuding, Yunnan, containing 38% iron and 0.8% phosphorus, the raw ore is crushed with a crusher to less than 30mm, roasted at 400°C for 10 minutes, and then ground with a ball mill to make 80% of the 100-mesh material Slurry is subjected to strong magnetic roughing under a strong magnetic field of about 4000 Gauss, and the roughed gangue slurry is sent to a sedimentation tank for settlement. Roughly selected qualified iron ore, add 4% sulfuric acid solution, soak for 1.5 hours in an acidic environment, and then send it to the ultrasonic chemical dephosphorization plate tank after stirring. Under the action of 4 kHz ultrasonic waves, the iron ore particles are continuously strengthened and decomposed In 25 to 30 minutes, 80%-85% of the phosphorus in the iron ore is decomposed and removed by acid, and then about 2000 Gauss weak magnetic separation can be carried out to obtain an iron concentrate with a phosphorus content of less than 0.25...

Embodiment 3

[0017] Oolitic high-phosphorus iron ore in Lufeng, Yunnan, containing 48% iron and 0.8% phosphorus, was crushed with a crusher to less than 30mm, roasted at 800°C for 15 minutes, and then ground with a ball mill to make 80% slurry over 150 mesh. Strong magnetic roughing is carried out under a magnetic field of about 4000 Gauss, and the roughed gangue slurry is sent to the sedimentation tank for settlement. Roughly selected qualified iron ore, add 10% hydrochloric acid solution, soak for 5 hours in an acidic environment, and then send it to the ultrasonic chemical dephosphorization tank after stirring. In ~25 minutes, 80% - 85% of the phosphorus in the iron ore is decomposed and removed by acid, and then about 2000 Gauss weak magnetic separation can be performed to obtain an iron concentrate with a phosphorus content of less than 0.25% and an iron grade of more than 60%, which fully meets the requirements Metallurgical material requirements. The tailings slurry produced by mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com