Lanthanum-modified biochar, and preparation method and application thereof

A biochar, modified technology, applied in the preparation/purification of carbon, chemical instruments and methods, water pollutants, etc., can solve the adsorption effect (the adsorption capacity is not particularly ideal, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a kind of preparation method of lanthanum modified biochar, comprising the following steps:

[0034] Pyrolyzing sheep manure to obtain sheep manure biochar;

[0035] After the sheep dung biochar is washed, it is soaked in a lanthanum chloride solution, and the pH value is adjusted to 8-11 to obtain the lanthanum-modified biochar.

[0036] In the invention, sheep manure is pyrolyzed to obtain sheep manure biochar.

[0037] The present invention does not have any special limitation on the source of the sheep manure, and the sources well known to those skilled in the art can be used.

[0038] Before the pyrolysis, the present invention preferably sieves the sheep manure; the present invention does not have any special limitation on the sieving, and adopts a process well known to those skilled in the art to ensure that the sieved sheep manure The particle size can be below 840 microns.

[0039] In the present invention, the pyrolysis temperature is...

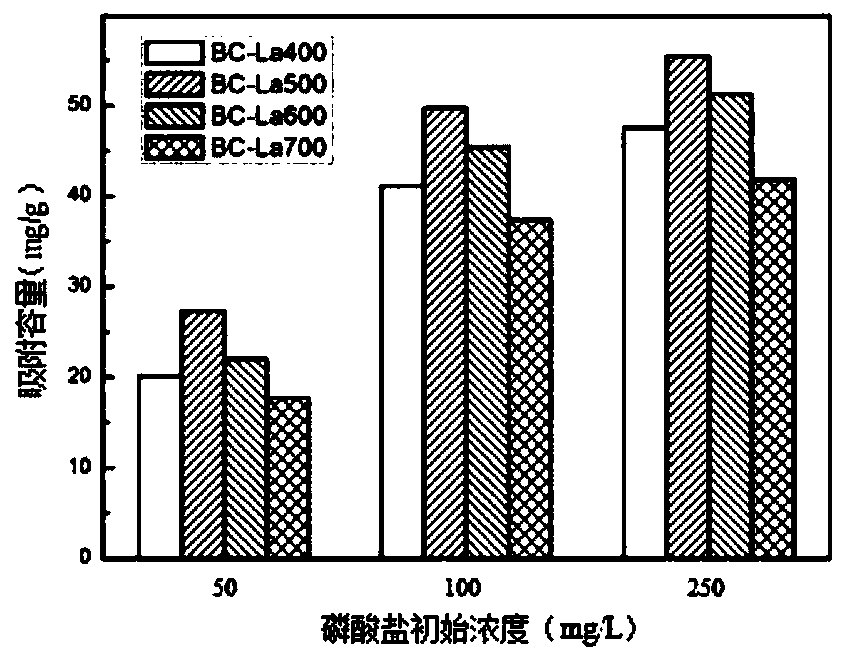

Embodiment 1

[0063] Pass sheep manure through a 20-mesh sieve, and place it in a crucible for pyrolysis (500°C, 2h) to obtain sheep manure biochar (referred to as BC-500);

[0064] Grind the sheep dung biochar and pass it through a 60-mesh sieve, mix 10 g of the sieved sheep dung biochar with 500 mL of hydrochloric acid with a concentration of 1 mol / L, stir evenly, let stand for 30 minutes, and pass through a 0.45 μm microporous membrane Carry out suction filtration, repeat the above process of mixing, stirring, standing and suction filtration 3 times, mix with 1000mL deionized water (resistivity 18.2MΩ·cm), stir well, let stand for 30min, pass through 0.45μm microporous filter After the membrane is suction-filtered, it is dried (105° C.) to constant weight to obtain sheep manure biochar after charcoal washing;

[0065] Mix the sheep dung biochar after the charcoal washing treatment with 500mL of lanthanum chloride solution with a concentration of 0.5mol / L, stir evenly and let stand for 30...

Embodiment 2

[0067] Pass sheep manure through a 20-mesh sieve, and place it in a crucible for pyrolysis (400°C, 2h) to obtain sheep manure biochar (referred to as BC-400);

[0068] Grind the sheep dung biochar and pass it through a 60-mesh sieve, mix 10 g of the sieved sheep dung biochar with 500 mL of hydrochloric acid with a concentration of 1 mol / L, stir evenly, let stand for 30 minutes, and pass through a 0.45 μm microporous membrane Carry out suction filtration, repeat the above process of mixing, stirring, standing and suction filtration 3 times, mix with 1000mL deionized water (resistivity 18.2MΩ·cm), stir well, let stand for 30min, pass through 0.45μm microporous filter After the membrane is suction-filtered, it is dried (105° C.) to constant weight to obtain sheep manure biochar after charcoal washing;

[0069] Mix the sheep dung biochar after the charcoal washing treatment with 500mL of lanthanum chloride solution with a concentration of 0.5mol / L, stir evenly and let stand for 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com