Bottom blowing oxygen converter smelting process control method based on molten steel continuous temperature measurement

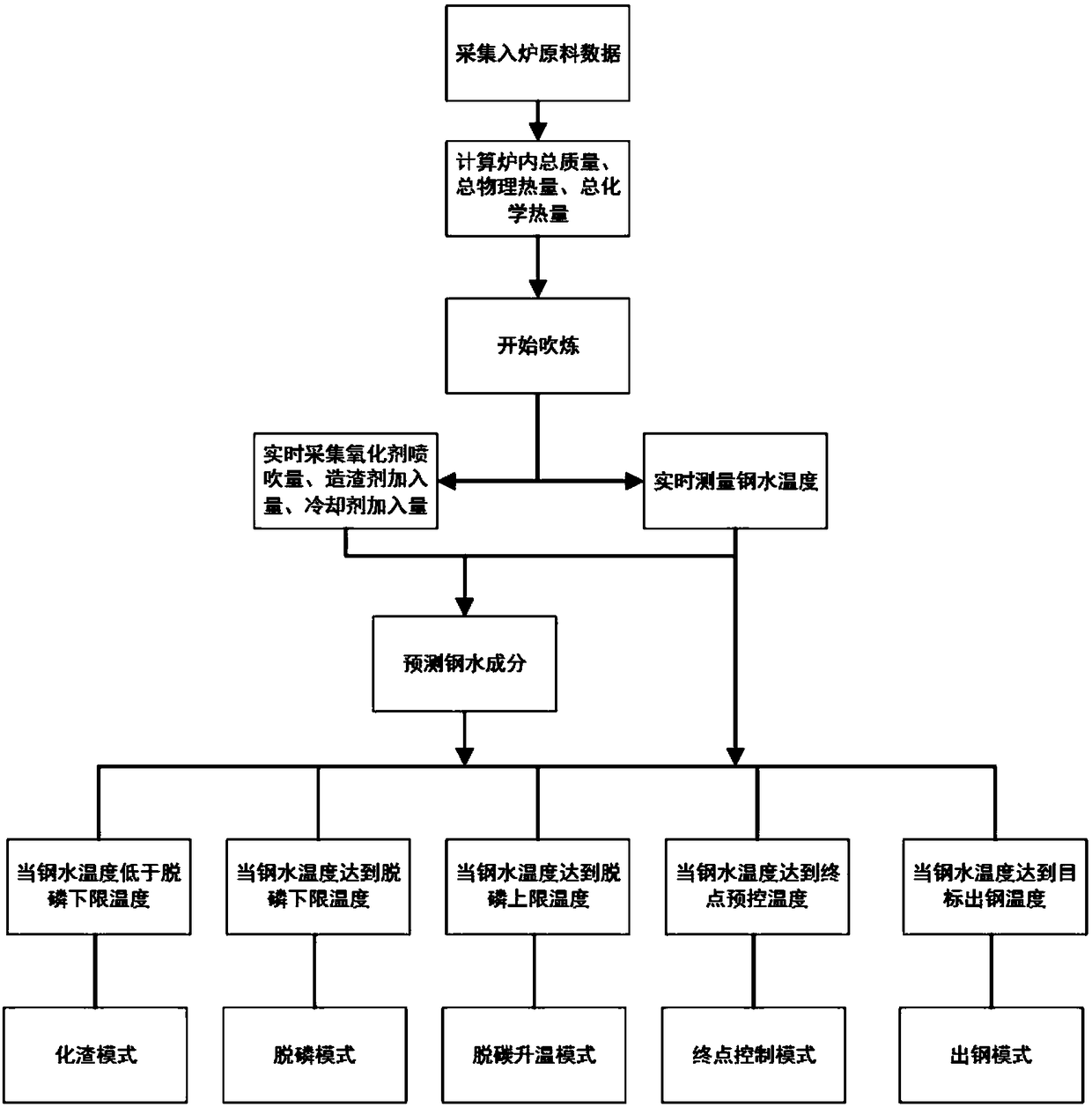

A technology of oxygen converter and smelting process, which is applied in the manufacture of converters, etc. It can solve the problems of molten steel temperature, composition prediction, unstable accuracy, and delayed response state of measurement data, so as to reduce the consumption of steel materials, increase the double hit rate, The effect of improving the dephosphorization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

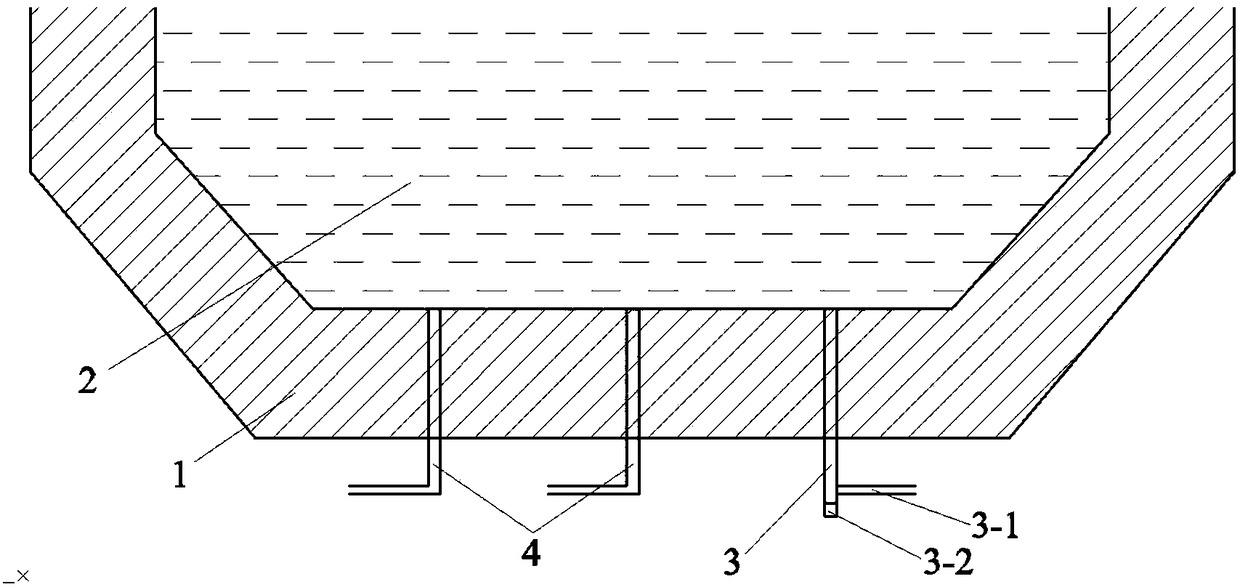

[0043] This embodiment is applied to a 100-ton bottom-blown oxygen converter. The bottom of the bottom-blown oxygen converter is equipped with 1 temperature-measuring lance and 4 bottom-blown lances. Arranged symmetrically on both sides of the trunnion centerline. The temperature measuring gas used by the temperature measuring spray gun is O 2 -N 2 -Ar mixed gas, the gas supply strength of the bottom blowing gun is 0.8Nm 3 / t / min, powder supply intensity is 2~4kg / t / min. The dephosphorization lower limit temperature set by the converter is 1350°C, the dephosphorization upper limit temperature is 1400°C, and the end point pre-control temperature is 50°C lower than the tapping target temperature.

[0044] After adopting the control method of the present invention, the double hit rate of the end point temperature and carbon content reaches 99.6%, and the phosphorus content of the end point molten steel is stably controlled within 80ppm, and the steel material consumption of the...

Embodiment 2

[0046] This embodiment is applied to a 300-ton bottom-blown oxygen converter. The bottom of the bottom-blown oxygen converter is equipped with 1 temperature-measuring lance and 8 bottom-blown lances. Arranged symmetrically on both sides of the trunnion centerline. The temperature measuring gas used by the temperature measuring spray gun is O 2 -CO 2 Mixed gas, the gas supply strength of the bottom blowing spray gun is 1.0Nm 3 / t / min, the powder supply intensity is 2.5~5kg / t / min. The dephosphorization lower limit temperature set by the converter is 1360°C, the dephosphorization upper limit temperature is 1390°C, and the end point pre-control temperature is 30°C lower than the tapping target temperature.

[0047] After adopting the control method of the present invention, the double hit rate of the end point temperature and carbon content reaches 99.2%, and the phosphorus content of the end point molten steel is stably controlled within 75ppm, and the steel material consumpti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com