Method for improving utilization efficiency of ozone and reducing COD of wastewater

A waste water and ozone technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water pollutants, etc., can solve the problems affecting the removal effect of hydroxyl radical scavenger, affecting the efficiency of ozone utilization, complicated operation process, etc., to achieve Improve ozone utilization efficiency, increase reaction rate and utilization efficiency, and reduce the effect of total phosphorus content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

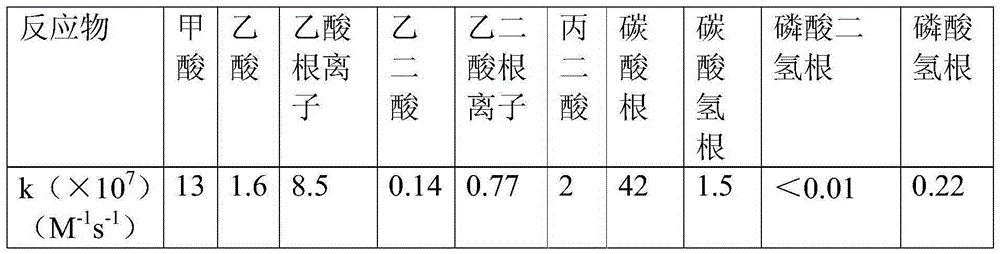

Method used

Image

Examples

Embodiment 1

[0041] In the ozone oxidation reactor with a volume of 1.2L, the bottom is passed through flocculation pretreated styrene-butadiene rubber waste water (a water outlet is provided on the upper part of the reactor, and the volume of water in the reactor is 0.9L), and the waste water COD is 721mg / L, the total phosphorus is 133mg / L, add 10% calcium oxide suspension prepared with styrene-butadiene rubber wastewater into the reactor inlet pipe, so that the concentration of calcium hydroxide in the wastewater is 2.0g / L, in the reactor Ozone with a concentration of 85mg / L is passed into the bottom of the reactor, and the air intake is 1.5L / min. After the wastewater stays in the ozonation reactor for 35 minutes, the sample is taken. The COD content of the water measured after the sample is filtered with fast filter paper is 48.5mg / L. , the total phosphorus content is 0.04mg / L. As a comparison, the above calcium oxide was converted to 2.15g / L of sodium hydroxide containing equivalent h...

Embodiment 2

[0043] The bottom of the ozonation reactor with a volume of 1.2L is passed into the oilfield heavy oil wastewater after flocculation pretreatment (a water outlet is provided on the upper part of the reactor, and the volume of water in the reactor is 0.9L), and the COD of the wastewater is 332mg / L, the total phosphorus content is 0.02mg / L, in the reactor, add the suspension of 10% calcium oxide prepared with oil field heavy oil wastewater, make the concentration of calcium oxide in the wastewater be 1.65g / L, in the reactor Ozone with a concentration of 85mg / L is passed into the bottom, and the intake rate is 1.5L / min. After the wastewater stays in the ozonation reactor for 20 minutes, it is sampled. The COD content of the water measured after the sample is filtered with fast filter paper is 45.2mg / L. Total phosphorus was not detected. As a comparison, the above calcium oxide was converted to 1.75g / L of sodium hydroxide containing equivalent hydroxide ion concentration, the sam...

Embodiment 3

[0045] In the ozone oxidation reactor with a volume of 1.2L, the acrylonitrile wastewater after flocculation pretreatment is passed into the bottom (a water outlet is provided on the upper part of the reactor, and the volume of water in the reactor is 0.9L), and the COD of the wastewater is 2451mg / L , in the reactor, add the suspension of 10% calcium oxide prepared with acrylonitrile waste water, make the concentration of calcium hydroxide in the waste water be 10g / L, pass into the ozone of 85mg / L concentration at the bottom of the reactor, carry out The gas volume is 1.5L / min. After the wastewater stays in the ozonation reactor for 90 minutes, the sample is taken. The COD content of the water measured after the sample is filtered with fast filter paper is 49.7mg / L. As a comparison, the above calcium oxide was converted into sodium hydroxide containing equivalent hydroxide ion concentration, and the amount of sodium hydroxide was 10.75g / L to carry out the same experiment, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com