High-entropy ceramic-based composite material and preparation method thereof

A composite material and ceramic-based technology, which is applied in the field of preparation of ceramic-based composite materials, can solve problems such as poor toughness and high brittleness of high-entropy ceramic materials, and achieve the effects of solving brittleness problems, improving mechanical properties, and being easy to implement industrially

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

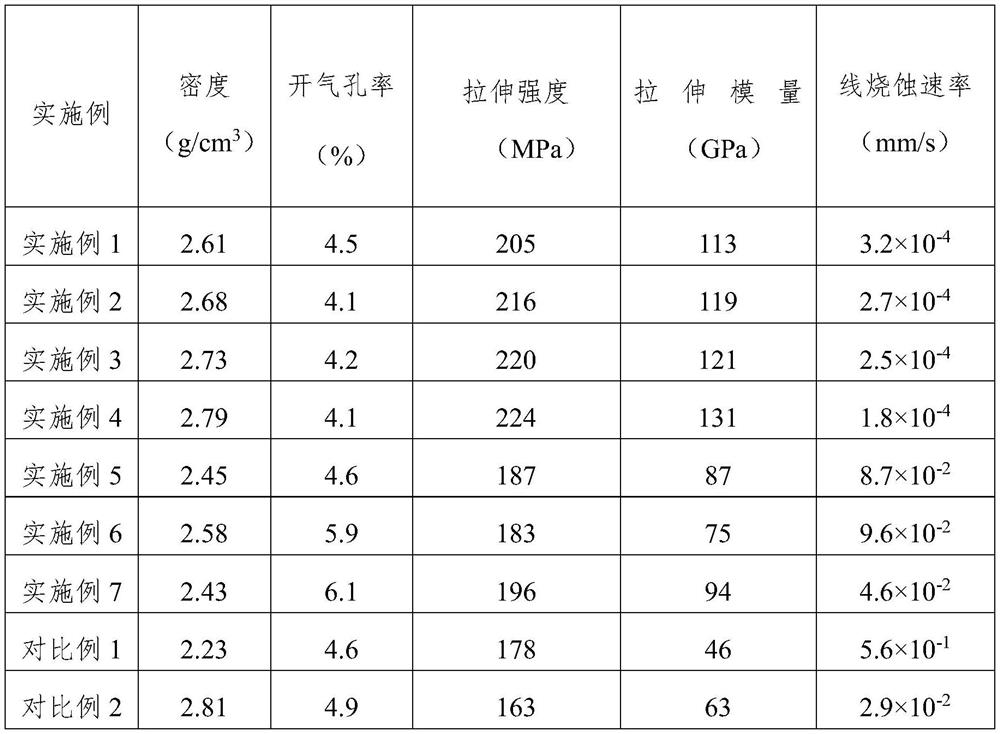

Examples

preparation example Construction

[0024] The present invention provides a kind of preparation method of high-entropy ceramic matrix composite material in the first aspect, described method comprises the following steps:

[0025] (1) The preparation contains (Ti x1 Zr x2 f x3 Nb x4 Ta x5 ) The high-entropy ceramic slurry of C high-entropy ceramic powder and phenolic resin (also denoted as (Ti x1 Zr x2 f x3 Nb x4 Ta x5 ) C high-entropy ceramic slurry); the solid component of the high-entropy ceramic slurry is (Ti x1 Zr x2 f x3 Nb x4 Ta x5 ) C high-entropy ceramic powder, the liquid component is a phenolic resin and is preferably a high residual carbon phenolic resin; in the present invention, the (Ti x1 Zr x2 f x3 Nb x4 Ta x5 )C high-entropy ceramic powder is a single rock-salt phase structure, which is a single-phase eutectic solution composed of Ti, Zr, Hf, Nb, Ta and C elements. The atomic percentage expression is (Ti x1 Zr x2 f x3 Nb x4 Ta x5 ) C; the present invention to the (Ti x1 Zr...

Embodiment 1

[0044] A (Ti x1 Zr x2 f x3 Nb x4 Ta x5 ) The preparation method of C high-entropy ceramic matrix composite material, its concrete steps are:

[0045] ① Preparation (Ti x1 Zr x2 f x3 Nb x4 Ta x5 )C high-entropy ceramic slurry: with (Ti x1 Zr x2 f x3 Nb x4 Ta x5 )C high-entropy ceramic powder is a solid component, and a high-carbon-residue phenolic resin with a carbon residue rate of 25% is a liquid component (Ti x1 Zr x2 f x3 Nb x4 Ta x5 ) C high-entropy ceramic slurry; the (Ti x1 Zr x2 f x3 Nb x4 Ta x5 )C high-entropy ceramic powder is a single-phase co-solution composed of Ti, Zr, Hf, Nb, Ta and C elements; wherein, x1+x2+x3+x4+x5=1, and x1, x2, x3, x4 , x5 are all taken as 0.2; the prepared high-entropy ceramic slurry contains (Ti x1 Zr x2 f x3 Nb x4 Ta x5 ) The mass percentage of C high-entropy ceramic powder is 5%.

[0046] ② Preparation (Ti x1 Zr x2 f x3 Nb x4 Ta x5 )C high-entropy ceramic matrix composite material intermediate: (Ti x1 Z...

Embodiment 2

[0052] A (Ti x1 Zr x2 f x3 Nb x4 Ta x5 ) The preparation method of C high-entropy ceramic matrix composite material, its concrete steps are:

[0053] ① Preparation (Ti x1 Zr x2 f x3 Nb x4 Ta x5 )C high-entropy ceramic slurry: with (Ti x1 Zr x2 f x3 Nb x4 Ta x5 )C high-entropy ceramic powder is a solid component, and a high-carbon-residue phenolic resin with a carbon residue rate of 25% is a liquid component (Ti x1 Zr x2 f x3 Nb x4 Ta x5 ) C high-entropy ceramic slurry; the (Ti x1 Zr x2 f x3 Nb x4 Ta x5)C high-entropy ceramic powder is a single-phase co-solution composed of Ti, Zr, Hf, Nb, Ta and C elements; wherein, x1+x2+x3+x4+x5=1, and x1, x2, x3, x4 , x5 are all taken as 0.2; the prepared high-entropy ceramic slurry contains (Ti x1 Zr x2 f x3 Nb x4 Ta x5 ) The mass percentage of C high-entropy ceramic powder is 10%.

[0054] ② Preparation (Ti x1 Zr x2 f x3 Nb x4 Ta x5 )C high-entropy ceramic matrix composite material intermediate: (Ti x1 Z...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com