Preparation method of molybdenum alloy, molybdenum alloy and application of molybdenum alloy

A technology of molybdenum alloy and molybdenum powder, which is applied in the field of molybdenum alloys, can solve the problems of high low-temperature brittleness of molybdenum materials, high processing difficulty, and brittle secondary crystallization of molybdenum.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for preparing a molybdenum alloy, comprising the steps of: taking molybdenum powder and strontium powder with a particle size of 300 meshes, adding them to a three-dimensional mixer and mixing them evenly to obtain a mixed powder, wherein the mass ratio of the molybdenum powder and the strontium powder is 1: 0.078; then the mixed powder is added to a cold isostatic press for compression molding to obtain a pressed green body with a thickness of 28mm, the pressed pressure is 500MPa, and the time is 60s; then the pressed green body is put into a vacuum furnace for sintering, get molybdenum alloy;

[0021] Among them, the sintering system is: heat at 600°C for 30 minutes; then heat up to 800°C and hold for 40 minutes; then heat up to 1200°C and hold for 1 hour; then heat up to 1500°C and hold for 1.5 hours; 2h, then raise the temperature to 1900°C and keep it warm for 2h.

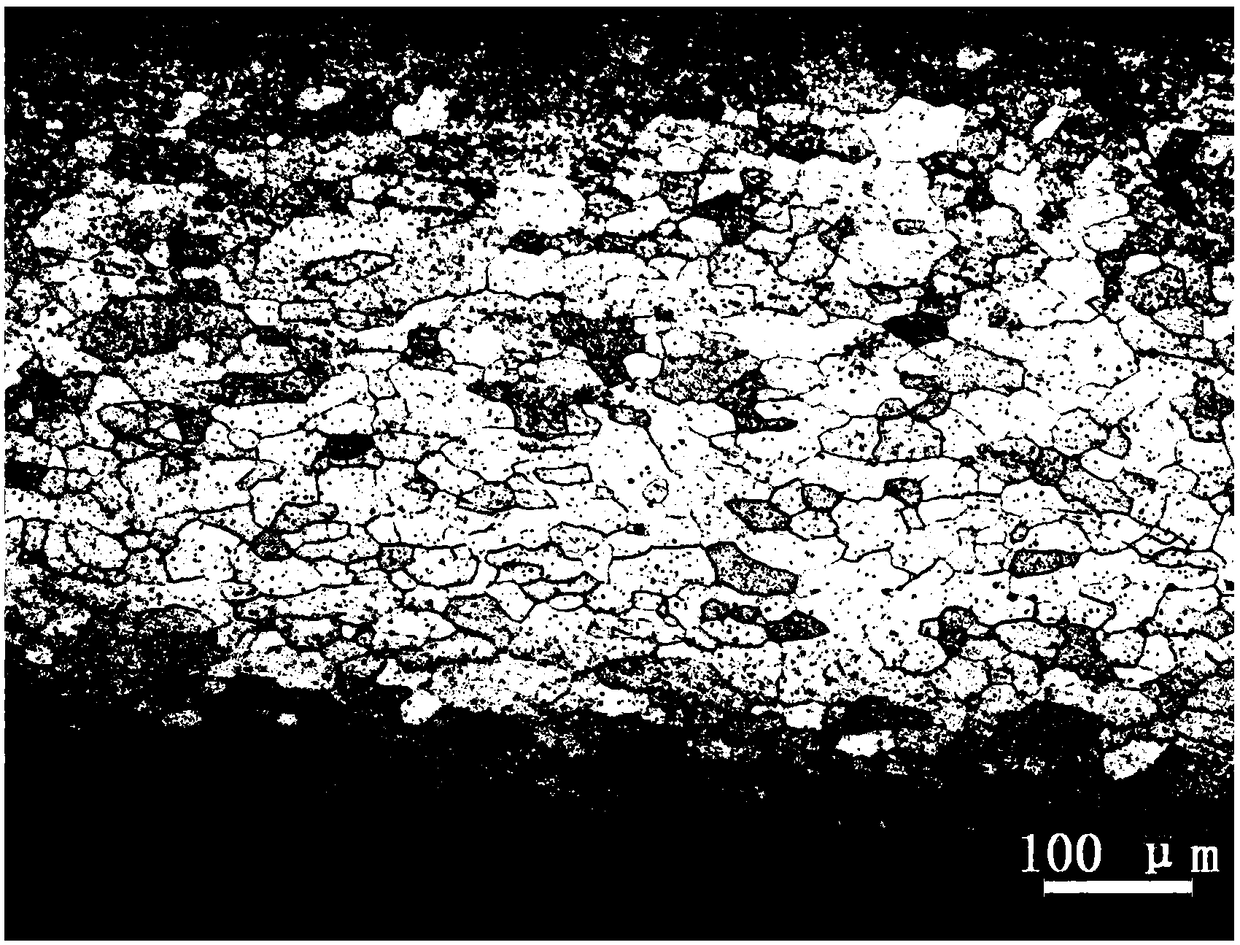

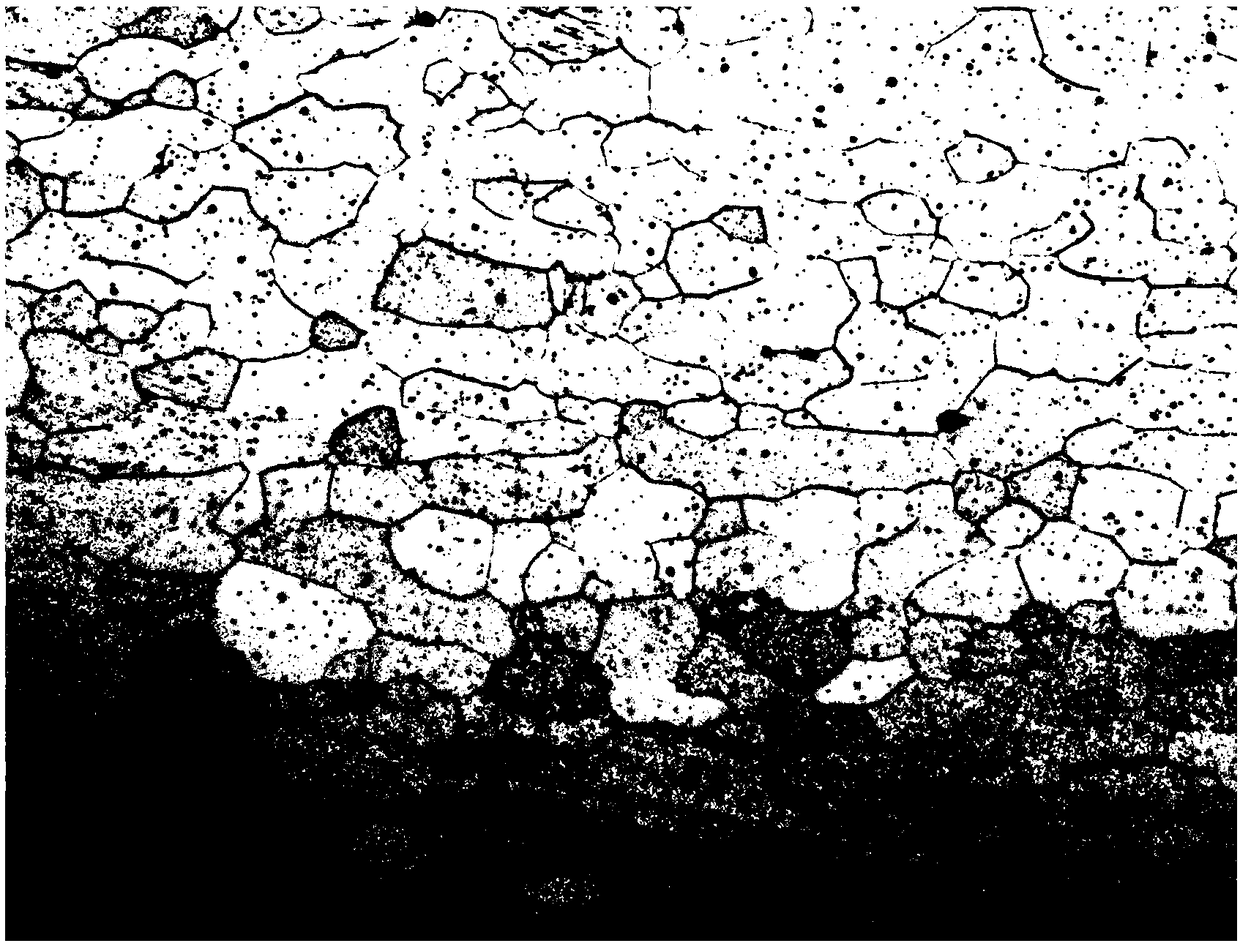

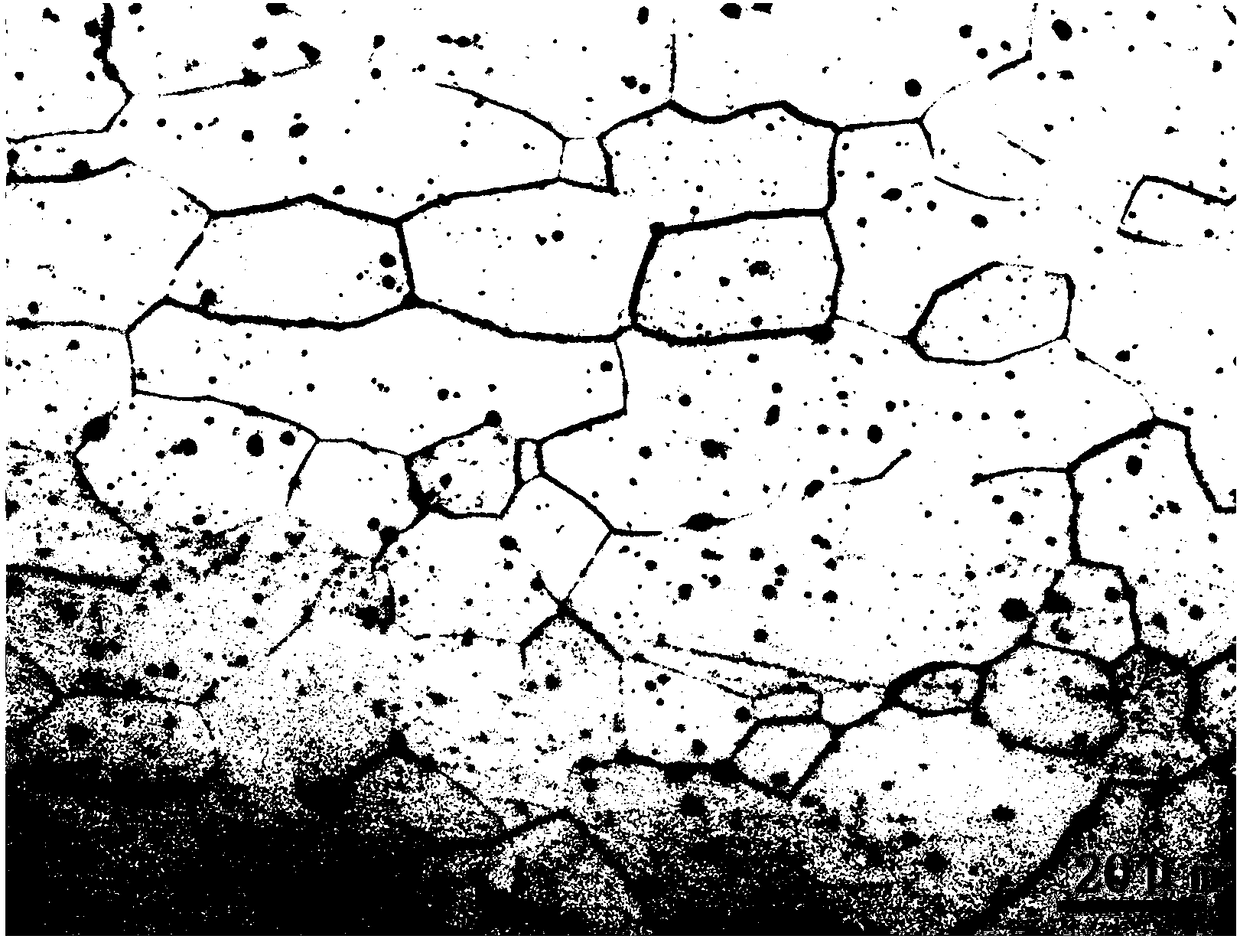

[0022] Preparation of the sample to be tested: take the sintered molybdenum alloy green bo...

Embodiment 2

[0030] A method for preparing a molybdenum alloy, comprising the steps of: taking molybdenum powder and strontium powder with a particle size of 300 meshes, adding them to a three-dimensional mixer and mixing them evenly to obtain a mixed powder, wherein the mass ratio of the molybdenum powder and the strontium powder is 1: 0.05; then the mixed powder is added to a cold isostatic press for compression molding to obtain a pressed green body with a thickness of 28mm, the pressed pressure is 400MPa, and the time is 30s; then the pressed green body is put into a vacuum furnace for sintering, get molybdenum alloy;

[0031] Among them, the sintering system is: heat at 600°C for 30 minutes; then heat up to 800°C and hold for 40 minutes; then heat up to 1200°C and hold for 1 hour; then heat up to 1500°C and hold for 1.5 hours; 2h, then raise the temperature to 1900°C and keep it warm for 2h.

[0032] Preparation of the sample to be tested: take the sintered molybdenum alloy green bod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com