Drilling fluid lubricant and drilling fluid

A drilling fluid and lubricant technology, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of increased wear of drill pipes and drill collars, increased pressure difference sticking, poor lubrication effect, etc., to achieve pressure reduction Poor sticking, reduced wear, good lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Synthesis of lubricants for drilling fluids:

[0014] According to the synthesis method and synthesis process technical conditions given, the lubricant for drilling fluid is synthesized according to the following weight ratio:

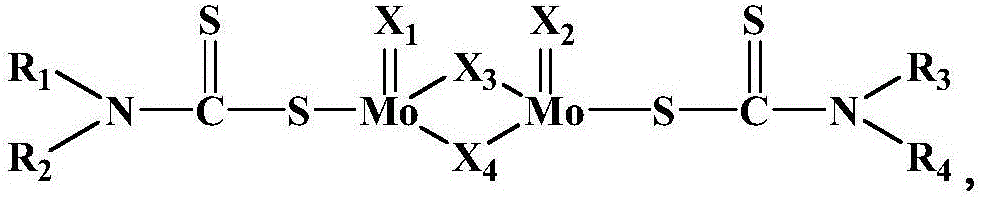

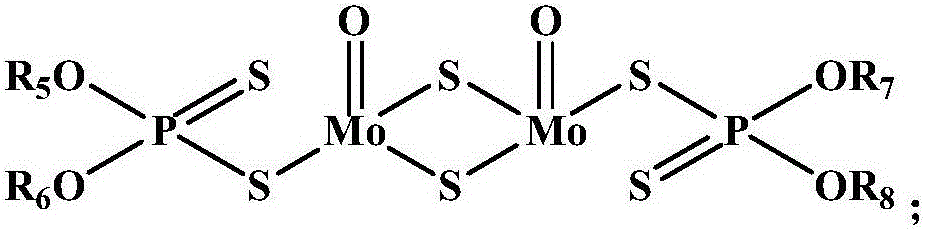

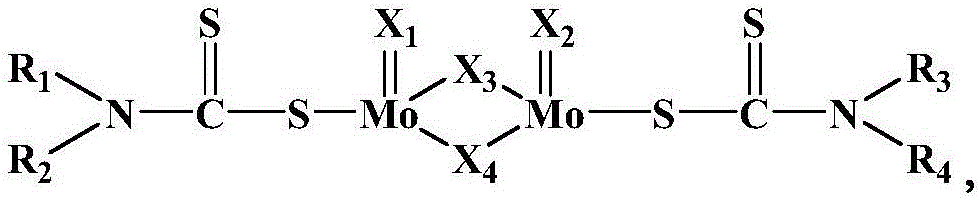

[0015] Base oil (special mineral oil), 4% surfactant (Span and Tween complexes), 2% carbon black (greater than 300 mesh), 5% molybdenum dialkyl dithiocarbamate, 5% bismuth Molybdenum Alkyl Dithiophosphate. The dark brown liquid obtained after the synthesis reaction is the lubricant for drilling fluid in Example 1 of the present invention.

[0016] Table 1 shows the lubricating performance evaluation results of the lubricant in this example in freshwater drilling fluid.

[0017] Table 1:

[0018] Lubricant addition / %

Adhesion coefficient reduction rate / %

Lubrication coefficient reduction rate / %

0

-

-

0.5

63.6

81.3

1.0

81.8

83.3

1.5

83.6

91.5

2.0

85.1

93...

Embodiment 2

[0022] Synthesis of lubricants for drilling fluids:

[0023] According to the synthesis method and synthesis process technical conditions given, the lubricant for drilling fluid is synthesized according to the following weight ratio:

[0024] Base oil (special mineral oil), 6% surfactant (Span class and Tween class compound), 2% carbon black (greater than 300 mesh), 10% molybdenum dialkyl dithiocarbamate, 10% bismuth Molybdenum Alkyl Dithiophosphate. The dark brown liquid obtained after the synthesis reaction is the extreme pressure lubricant for drilling fluid.

[0025] In this example, the composite brine drilling fluid was evaluated, and the reduction rate of the lubrication coefficient under different dosage conditions was measured respectively. The measurement results are shown in Table 2.

[0026] Table 2:

[0027] Lubricant addition / %

Lubrication coefficient reduction rate / %

0

0.815

-

1.0

0.489

40.0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com