Lubricating grease composition for cotton picker

A lubricating grease composition and composition technology, applied in the field of lubricating grease, can solve problems such as unreported and patented, and achieve good low-temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

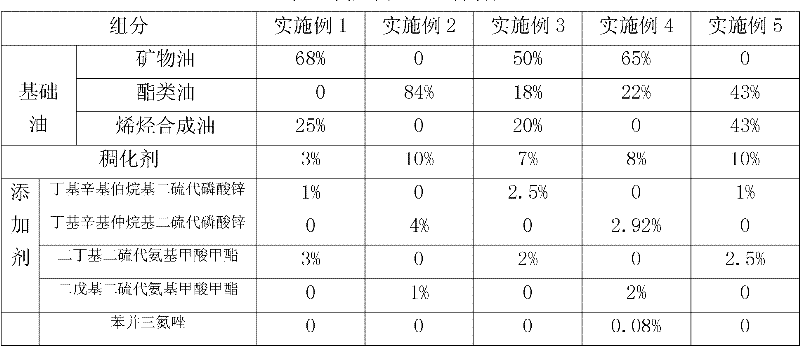

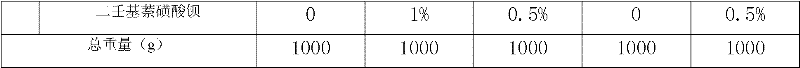

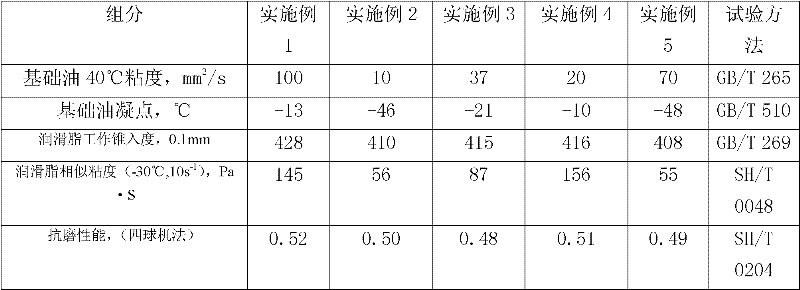

Embodiment 1

[0024] Put 30 grams of 12-hydroxy lithium stearate and 200 grams of mineral oil into the reactor, stir and heat to 210 ° C, add 480 grams of mineral oil into the reactor, continue stirring, add 250 grams of olefin synthetic oil, and stir. Cool down to 80°C, add 10 grams of butyl octyl primary alkyl zinc dithiophosphate and 30 grams of methyl dibutyl dithiocarbamate, and stir. The composition is oil-pressed three times by a three-roller machine, and then packed in a finished product.

Embodiment 2

[0026] Put 100 grams of 12-hydroxystearic acid lithium complex and 300 grams of ester oil into the reactor, stir and heat to 210 ° C, add 340 grams of ester oil in the reactor, continue stirring, add 200 grams of ester oil, Stir. Cool down to 80°C, add 40 grams of butyl octyl secondary alkyl zinc dithiophosphate, 10 grams of dipentyl methyl dithiocarbamate and 10 grams of basic barium dinonylnaphthalenesulfonate, and stir. The composition is oil-pressed three times by a three-roller machine, and then packed in a finished product.

Embodiment 3

[0028] Put 70 grams of 12-hydroxy lithium stearate and 300 grams of mineral oil into the reactor, stir and heat to 210 ° C, add 200 grams of mineral oil and 180 grams of ester oil into the reactor, continue stirring, and add 200 grams of olefin Synthetic oil, stir. Cool down to 80°C, add 25 grams of butyl octyl primary alkyl zinc dithiophosphate, 20 grams of methyl dibutyl dithiocarbamate and 5 grams of basic barium dinonylnaphthalenesulfonate, and stir. The composition is oil-pressed three times by a three-roller machine, and then packed in a finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com