Cooking control method of vacuum electric cooker

A control method and rice cooker technology, which is applied in the field of kitchen appliances, can solve the problems of long cooking time of rice and poor user experience, and achieve the effects of shortening the total cooking time, reducing the duration, and avoiding bluntness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

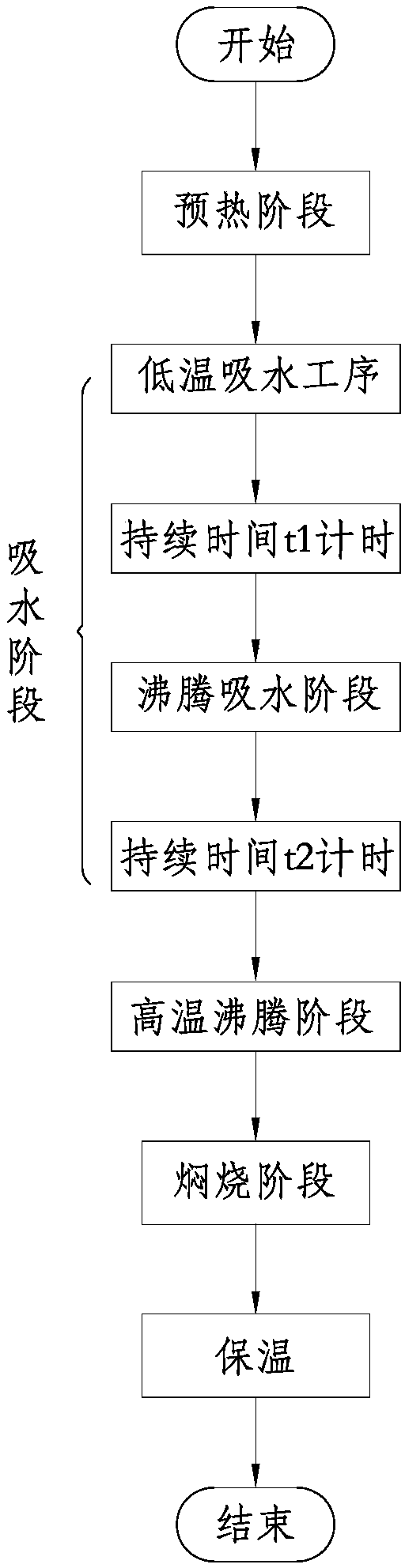

Embodiment 1

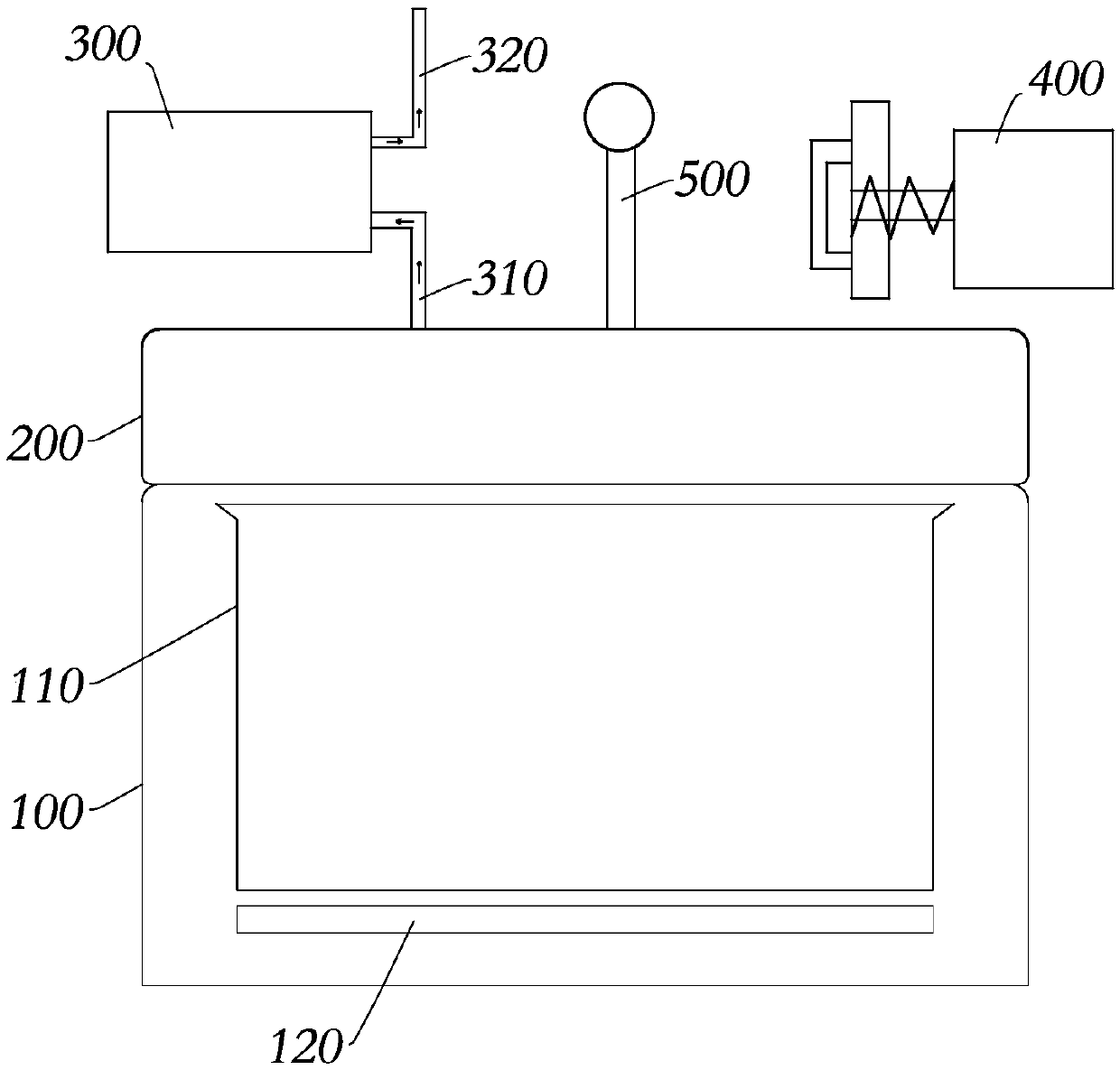

[0040] Reference figure 1 , The cooking control method of the vacuum rice cooker proposed in the first embodiment of the present invention, wherein the vacuum rice cooker includes a pot body 100, a pot cover 200 and an air extraction device, the pot cover 200 is covered on the pot body 100 to form a cooking cavity, and the air extraction device is used To extract gas from the cooking cavity, so that the cooking cavity forms a negative pressure. Specifically, the pot body 100 is provided with an inner pot 110 and a heating device 120 for heating the inner pot 110. When the pot cover 200 is closed on the pot body 100, it forms a cooking cavity with the inner pot 110. The heating device 120 may be a heating plate. The heating plate is located at the bottom of the pot body 100 for heating the bottom of the inner pot 110. The heating device 120 can also be an electromagnetic coil, which can realize the heating of the bottom of the inner pot 110 or the three-dimensional heating of the...

Embodiment 2

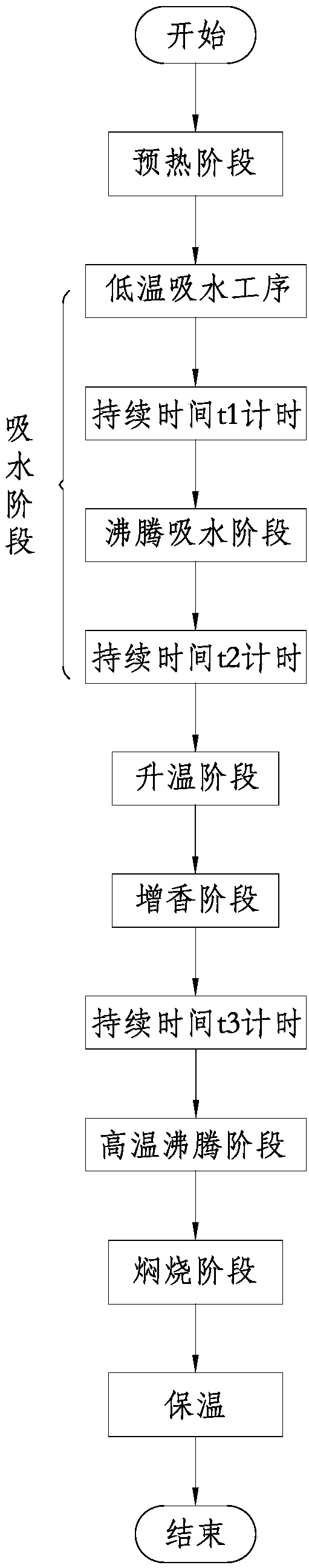

[0053] Reference image 3 In this embodiment, a flavor enhancement stage is set on the basis of the first embodiment. The flavor enhancement stage is carried out between the water absorption stage and the high-temperature boiling stage. In the flavor enhancement stage, the rice-water mixture in the cooking cavity is maintained at the flavor enhancement temperature T3. For extracting the aroma of food materials, the aroma enhancement temperature T3>90℃. By setting the flavoring stage, the rice will be thermally degraded at a flavoring temperature greater than 93°C, and a large amount of volatile odor components will be generated to form the flavor of the rice. The starch-fat complex in the rice grains will also be fully dissolved and separated at high temperatures. , Forming free fatty acids, and at the same time promoting the decomposition of esters in rice. The above-mentioned volatile odors and separation / decomposition products are the main substances in the aroma of rice, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com