Graphene oxide and/or phyllosilicate natural rubber composite material for space balloons and preparation method of graphene oxide and/or phyllosilicate natural rubber composite material

A layered silicate and composite material technology, applied in the field of composite material preparation, can solve problems such as poor compatibility and loss of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

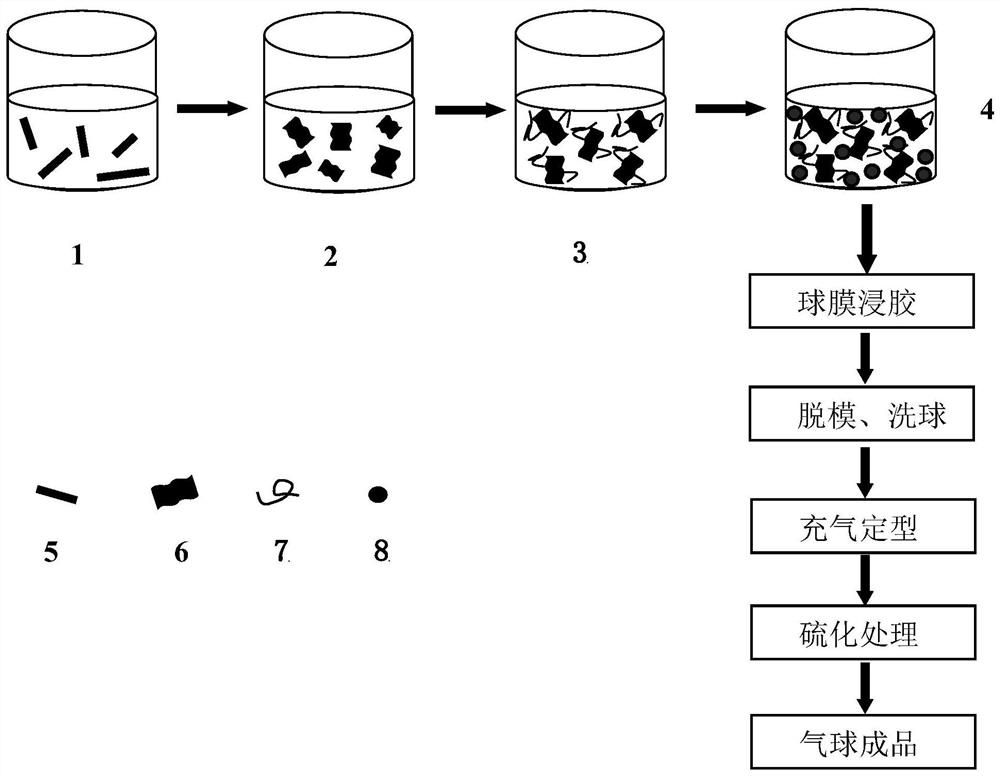

Method used

Image

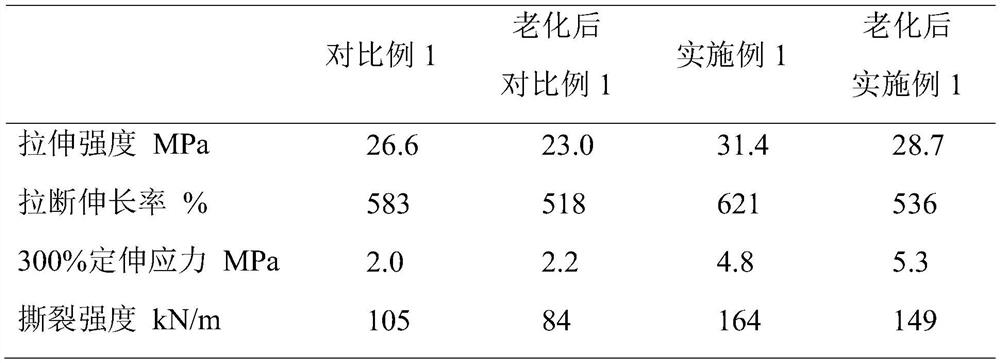

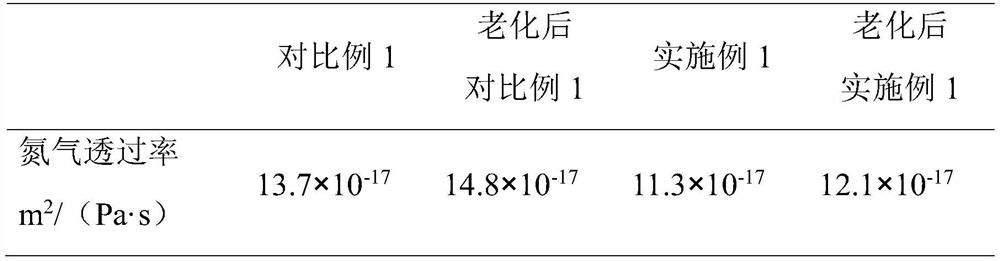

Examples

Embodiment 1

[0049] Weigh 150g of graphite oxide slurry with a concentration of 2%, in which the solid content of graphite oxide is 3g, add water to dilute to a concentration of 3‰, adjust the pH to 8, and then use a cell pulverizer for ultrasonication, with a working interval of 2s and a power of 750W , time 60min, wherein tested by the atomic force electron microscope (AFM), the graphene oxide in the graphene oxide aqueous dispersion is 1.5μm in lateral dimension, the thickness of the graphene oxide sheet is 0.9nm, and the number of layers is 3 layers; then at 70 ℃ Next, add 0.3g interface agent aminopropyltriethoxysilane coupling agent (KH550) to the graphene oxide aqueous dispersion, and carry out mechanical stirring at 100r / min for 6h, and the modified graphene oxide obtained by filtering the residue Dispersions;

[0050] Get 165g of natural rubber latex with a solid content of 60%, add 1g of ammonia water as a stabilizer, and mix at room temperature. In order to prevent demulsificati...

Embodiment 2

[0067] (1) Take 150g of graphite oxide water slurry with a concentration of 4%, wherein the solid content of graphite oxide is 6g, add water to dilute to a concentration of 6‰, adjust the pH to 8, and then use a cell pulverizer to perform ultrasonication with a working interval of 2s. The power is 750W, and the time is 60min. According to the atomic force electron microscope (AFM) test, the graphene oxide in the graphene oxide aqueous dispersion has a lateral size of 1.5μm, a graphene oxide sheet thickness of 0.9nm, and the number of layers is 3 layers; then Add 0.6g interface agent γ-(methacryloyloxy)propyltrimethoxysilane coupling agent (KH570) to the graphene oxide aqueous dispersion at 70°C, and perform mechanical stirring at 100r / min for 6h, The modified graphene oxide dispersion obtained by filtering the residue;

[0068] (2) Get 165g of natural rubber latex with a solid content of 60%, add 5g of ammonia as a stabilizer, and mix at normal temperature. In order to prevent...

Embodiment 3

[0080] (1) Take 150g of graphite oxide water slurry with a concentration of 6%, wherein the graphite oxide has a solid content of 9g, add water to dilute to a concentration of 9‰, adjust the pH to 8, and then use a cell pulverizer to perform ultrasonication with a working interval of 2s. The power is 750W, and the time is 60min. According to the atomic force electron microscope (AFM) test, the graphene oxide in the graphene oxide aqueous dispersion has a lateral size of 1.5μm, a graphene oxide sheet thickness of 0.9nm, and the number of layers is 3 layers; then Add 0.9 g of epoxy natural rubber latex with an interface agent solid content of 40% to the graphene oxide aqueous dispersion at 70°C, and perform mechanical stirring at 100 r / min for 6 hours, and filter the residue for later use;

[0081] (2) Get 165g of natural rubber latex with a solid content of 60%, add 5g of KOH aqueous solution as a stabilizer, and mix at normal temperature. In order to prevent demulsification in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com