Modulation wave pumping rod electrical-heating oil extraction device

A technology for oil production equipment and sucker rods, which is applied to drill pipes, production fluids, earthwork drilling and production, etc., and can solve problems such as high loss, decreasing power of electrothermal conversion, and high accident rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

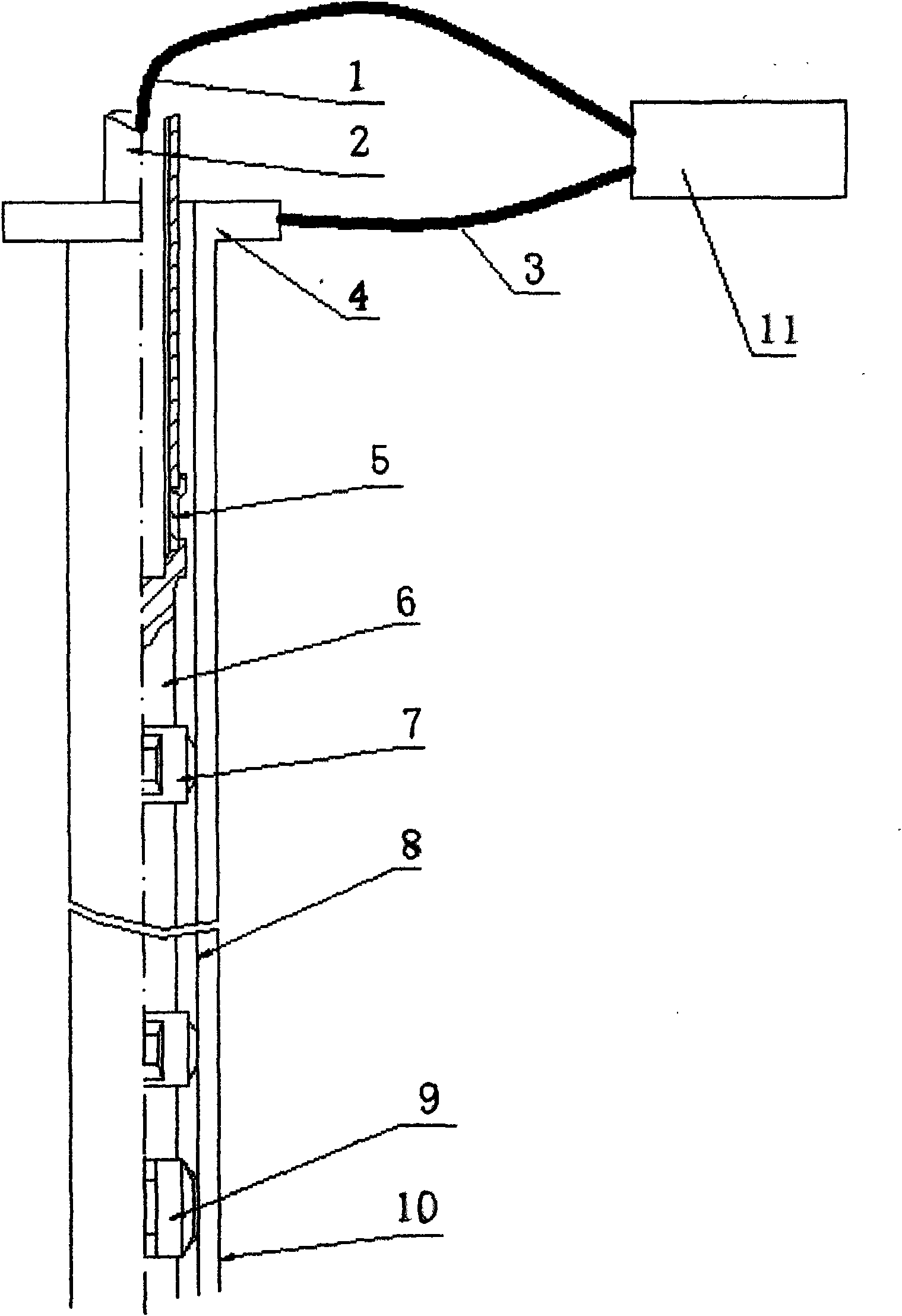

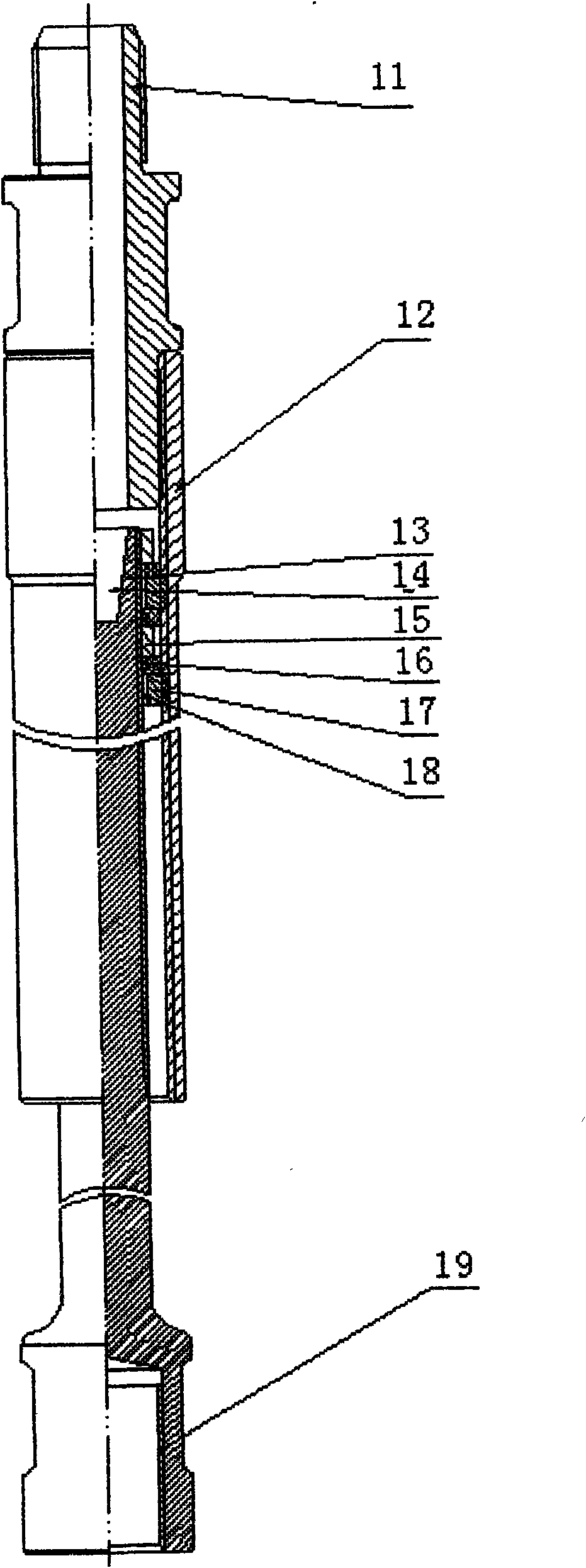

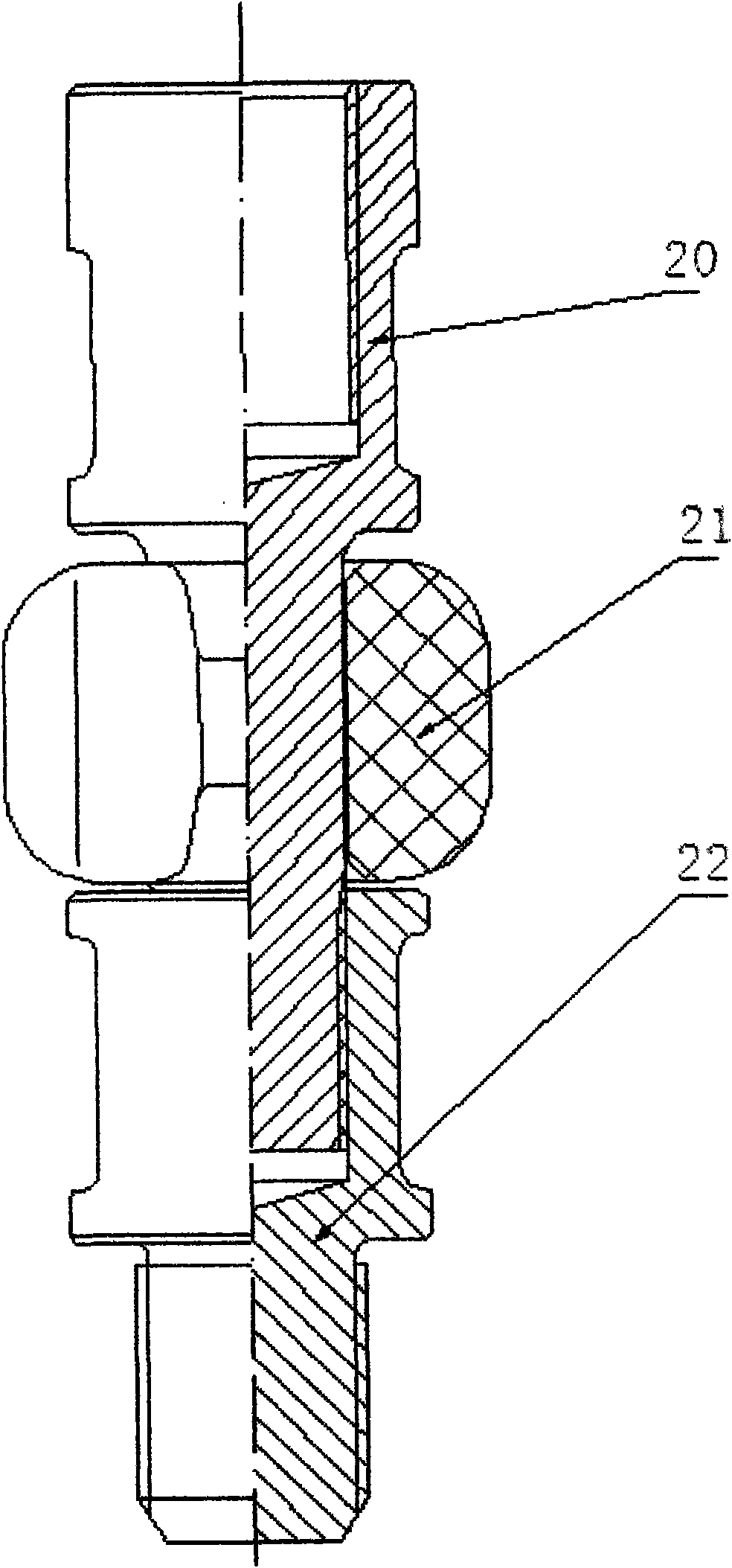

[0008] According to the accompanying drawings (such as figure 1 , figure 2 , image 3 (shown) further explains the present invention: a modulated wave sucker rod electrothermal oil production device, including 0-20Hz modulated wave power supply, hollow polished rod, hollow rod insulating pup, sucker rod, sucker rod collar insulating centralizer , incoming and outgoing cables and sliding contactors; wherein: the lower end of the hollow polished rod 2 is connected with a hollow rod insulating nipple 5, the upper and lower ends of which are in a good electrical insulation state, and the lower end of the incoming cable 1 passing through the hollow polished rod 2 is connected to the hollow The inner rod of the rod insulation nipple 5 is in good electrical connection, and the lower end of the hollow rod insulation nipple 5 is directly connected to the sucker rod 6; the sucker rod collar insulation centralizer 7 is installed at the coupling of each sucker rod 6 , used to prevent s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com