Device for measuring liquid level of liquefied natural gas cylinder

A liquefied natural gas and liquid level measurement technology, applied in the field of liquid level measurement devices, can solve the problems of complex structure of ultrasonic liquid level gauge, easy damage of float type liquid level gauge, difficulty in popularization and popularization, etc., and achieve good dynamic response characteristics, The effect of strong anti-overload ability and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

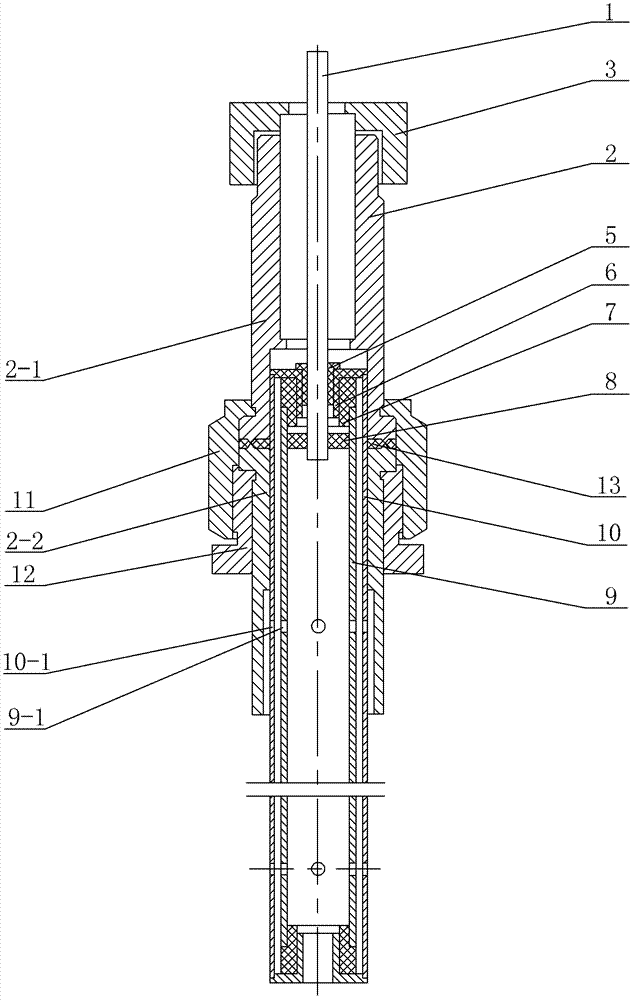

[0007] Specific implementation mode one: combine figure 1 Describe this embodiment, the liquid level measuring device of a kind of liquefied natural gas cylinder described in this embodiment comprises terminal post 1, shell assembly 2, compression nut 3, first insulating sleeve 4, guide sleeve 5, support sleeve 6, The second insulating sleeve 7, the positioning nut 8, the inner tube 9 and the outer tube 10, the terminal 1 is inserted in the housing assembly 2, and the upper end of the terminal 1 is exposed outside the housing assembly 2, and the first insulating sleeve 4 is set On the outer wall of the terminal 1, and the first insulating sleeve 4 is located between the outer wall of the terminal 1 and the inner wall of the housing assembly 2, the guide sleeve 5, the supporting sleeve 6, and the second insulating sleeve 7 are sequentially arranged from inside to outside. It is set on the outer wall of the lower part of the terminal 1, and the guide sleeve 5, the support sleeve...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination figure 1 To illustrate this embodiment, a liquid level measuring device for a liquefied natural gas cylinder in this embodiment further includes a lock nut 11 and a lock nut 12, and the housing assembly 2 includes an upper shell 2-1 and a lower shell The body 2-2, the upper casing 2-1 and the lower casing 2-2 are arranged sequentially from top to bottom, the lock nut 12 is set on the outer side wall of the upper end of the lower casing 2-2, and the upper part of the lock nut 11 The inner sidewall is threadedly connected to the outer sidewall of the lower end of the upper housing 2 - 1 , and the inner sidewall at the bottom of the lock nut 11 is threaded to the outer sidewall of the lock nut 12 . Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 To describe this embodiment, a sealing gasket 13 is provided at the joint between the upper casing 2-1 and the lower casing 2-2 of the liquid level measuring device for a liquefied natural gas cylinder described in this embodiment. Other components and connections are the same as those in the second embodiment.

[0011] working principle

[0012] When the present invention is used, a negative electrode is connected to the top of the inner tube 9, an anode is connected to the bottom of the outer tube 10, the present invention is put into a liquefied natural gas cylinder, and the lower part of the outer tube 10 is inserted under the liquid surface of the liquefied natural gas. When the liquid level in the bottle changes, the liquefied natural gas liquid enters the inner tube 9 through the second through hole 10-1 on the outer tube 10 and the first through hole 9-1 on the inner tube 9, and the inner tube 9 and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com