Multi-beam structure combined radio frequency micro electro mechanical system resonator and application

A micro-electromechanical system and resonator technology, applied in electrical components, impedance networks, etc., can solve the problems of increased device occupied space, affecting system stability, low electromechanical coupling coefficient, etc., to improve vibration amplitude, improve the effect of IoT, The effect of high Q

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

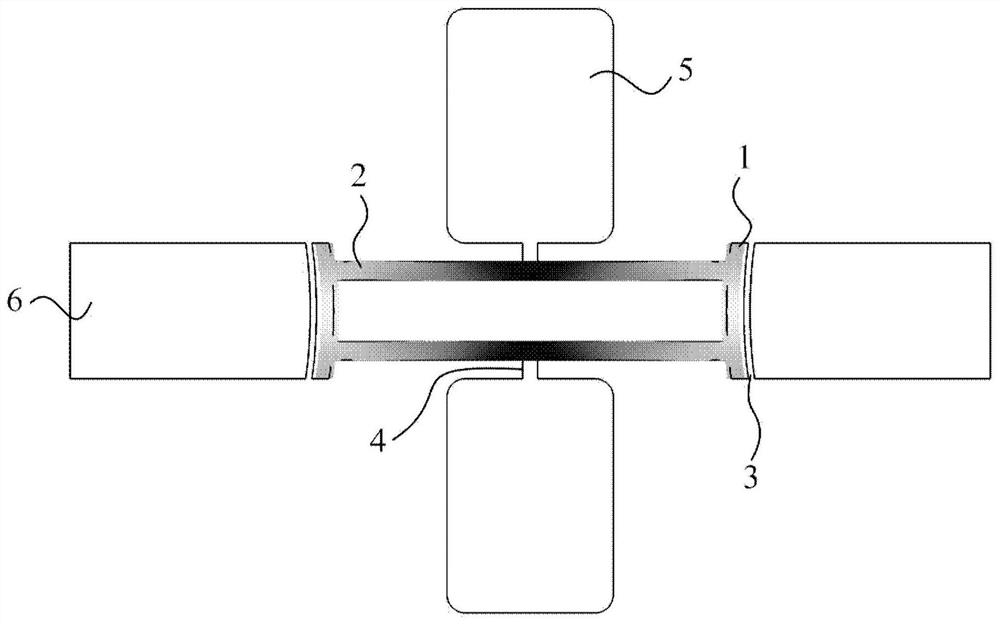

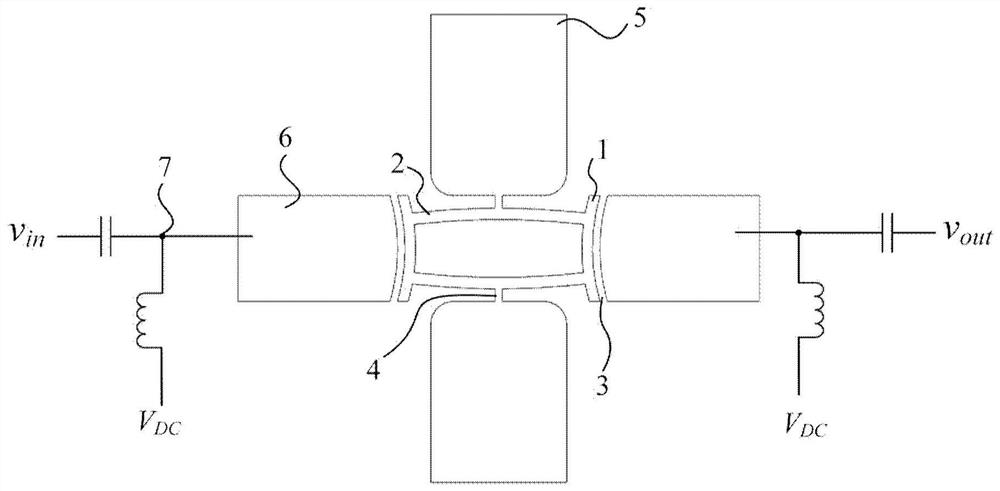

[0096] Such as figure 2 As shown, the present embodiment provides a radio frequency MEMS resonator with multi-beam structure combination.

[0097] The electromechanical conversion beam 1 is a parabolic curved beam, which uses arc design to increase the energy conversion area on the side of the beam, and the material used is single crystal silicon.

[0098] The energy transmission beam 2 is a parabolic curved beam, which is connected to the two electromechanical conversion beams 1 at the input and output ends to transmit vibration energy; the two energy transmission beams 2 are symmetrical about the central axis of the electromechanical conversion beam 1 .

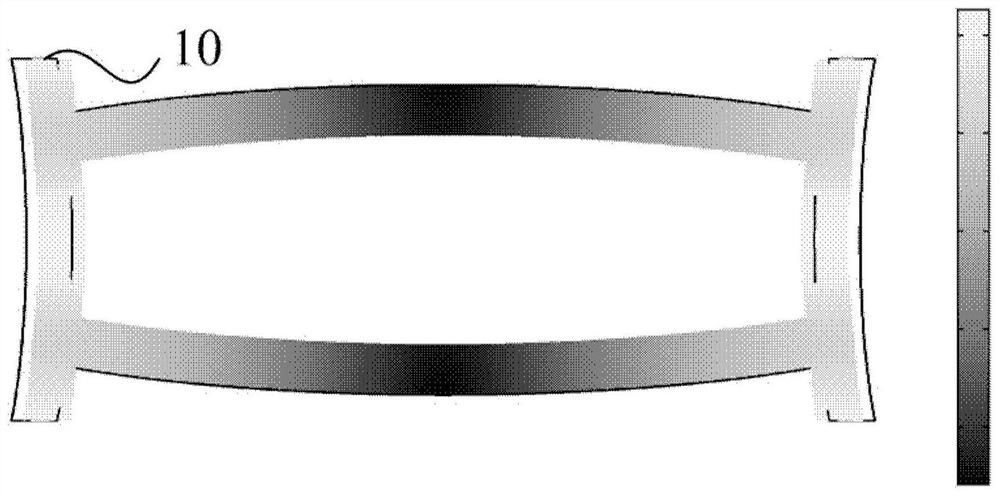

[0099] The electromechanical conversion beam 1 and the energy transmission beam 2 are both in-plane vibration modes, and the overall mode of the resonator formed by the coupling is an in-plane tensile mode 10, as shown in image 3 shown.

[0100] The electrode 6 is facing the side of the electromechanical conversion beam...

Embodiment 2

[0105] Such as Figure 4 As shown, this embodiment provides an arrayed beam resonator structure.

[0106] The electromechanical conversion beam 1 is a parabolic curved beam with a large-area energy conversion structure on the side of the beam, and the material is single crystal silicon.

[0107] The energy transmission beam 2 is a straight beam, which is connected to the two electromechanical conversion beams 1 at the input and output ends to transmit vibration energy; the two energy transmission beams 2 are symmetrical about the central axis of the electromechanical conversion beam 1, and the energy transmission beam 2 and the electromechanical conversion beam 1 form a substructure. resonance unit.

[0108] The sub-resonance unit forms a two-dimensional array structure through the secondary energy transmission beam 8 and the tertiary energy transmission beam 9. In this embodiment, the array scale of 2×2 is used; wherein, the secondary energy transmission beam 8 realizes the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com