Stable column type weighing sensor structure

A load cell and column technology, applied in the field of load cells, can solve the problems of poor lateral force resistance, poor overload resistance, and poor anti-overturning ability, and achieve good lateral force resistance and overload resistance. The effect of strong and anti-dumping ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

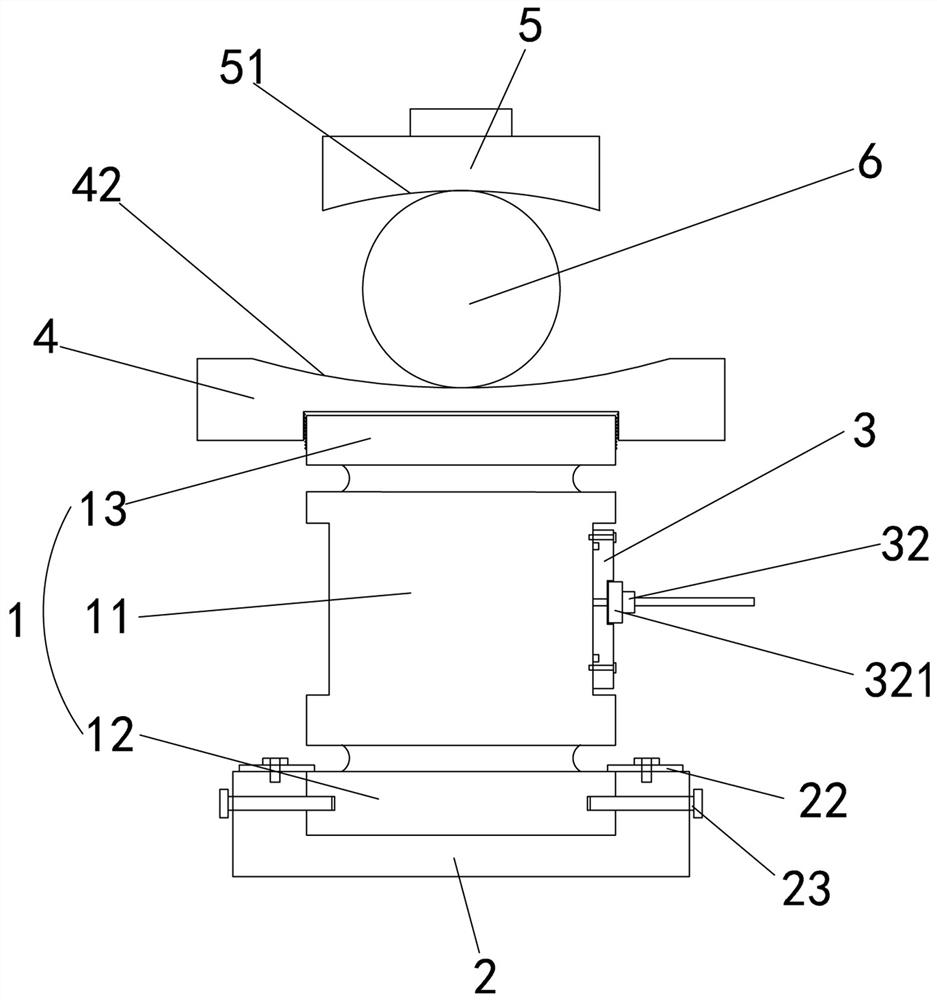

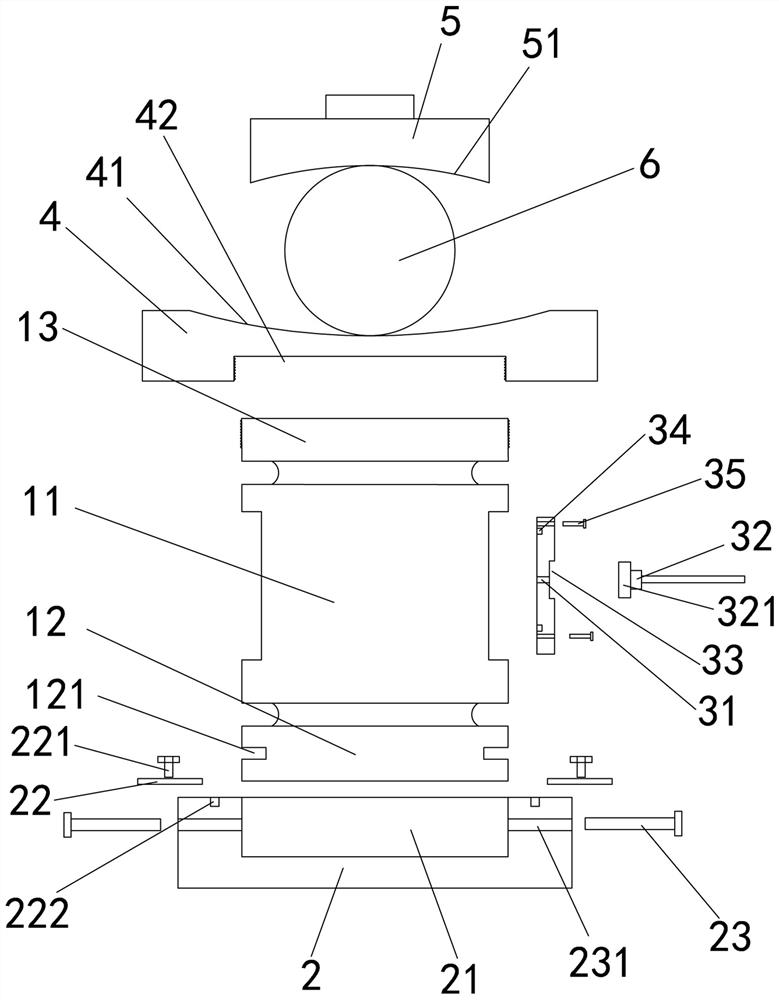

[0030] Embodiment one: if Figures 1 to 4 As shown, it is only one of the embodiments of the present invention, a stable column load cell structure, including an elastic body 1, a base 2 for supporting the elastic body 1, and a base for connecting the elastic body 1 The outlet plate 3, the expansion piece 4 set on the side of the elastic body 1 far away from the base 2, the pressure head 5 set on the side of the expansion piece 4 away from the base 2, and the expansion piece 5 set on the side of the expansion The steel ball 6 between the piece 4 and the indenter 5, the elastic body 1 includes a main body 11, a first connecting piece 12 and a second connecting piece 13, and the side of the first connecting piece 12 is provided with a first plug hole 121, the base 2 is provided with a fixing hole 21 for facilitating the insertion of the first connecting piece 12, a limiting plate 22 for connecting with the first connecting piece 12, and a limiting plate 22 for connecting with th...

Embodiment 2

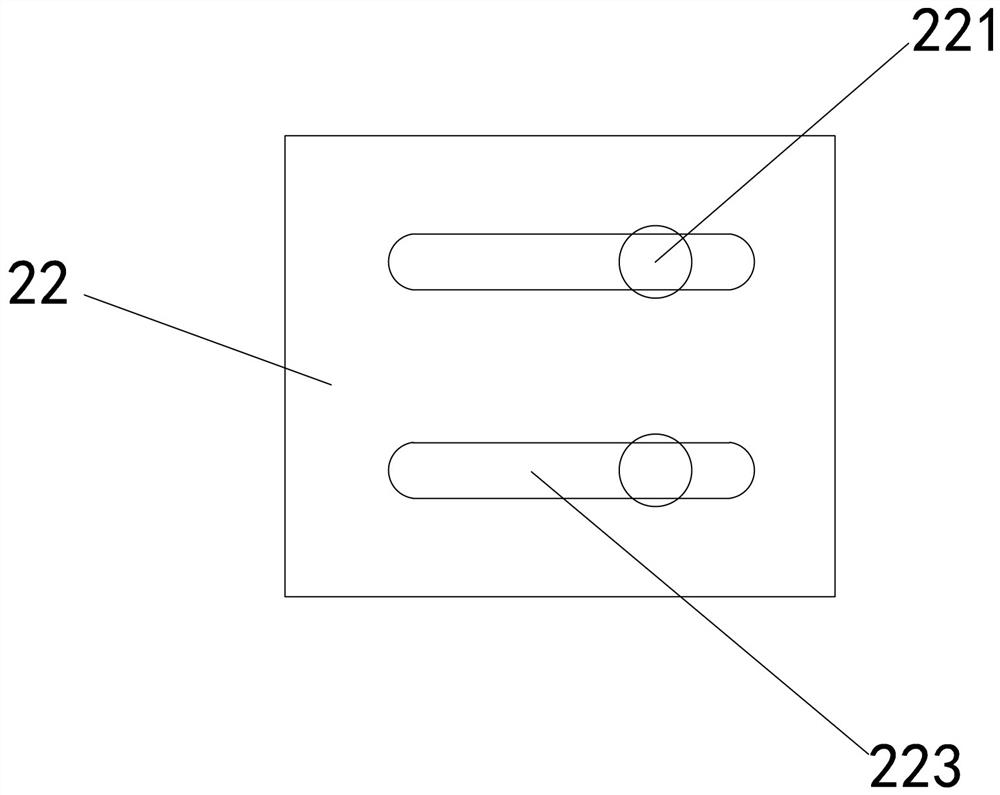

[0041] Embodiment two, still as Figures 1 to 4 As shown, it is only one of the embodiments of the present invention. On the basis of Embodiment 1, in a stable column type load cell structure of the present invention, the limiting plate 22 is provided with a convenient fixing bolt 221 passes through and slides the chute 223. That is to say, the fixing bolt 221 can slide in the chute 223, and when the fixing bolt 221 is unscrewed but not unscrewed, the position of the limiting plate 22 can be adjusted so that the limiting plate 22 can slide well and extend to The upper surface of the first connecting piece 12 completes the function of limiting the first connecting piece 12 .

[0042] Moreover, the strain gauge is a blind hole type or a through hole type, which is convenient to obtain the weight change above the device when straining.

[0043] In addition, a first external thread is provided on the outside of the second connecting piece 13, and a first internal thread matching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com