Micro machine differential capacitance accelerometer with symmetrical structure

A technology of accelerometer and differential capacitance, which is applied in the direction of measuring acceleration, speed/acceleration/impact measurement, generator/motor, etc. It can solve the problems of performance degradation of accelerometer temperature characteristics, low bonding efficiency, poor practicability, etc., to achieve Eliminate thermal mismatch stress, improve dynamic characteristics, and better anti-overload performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

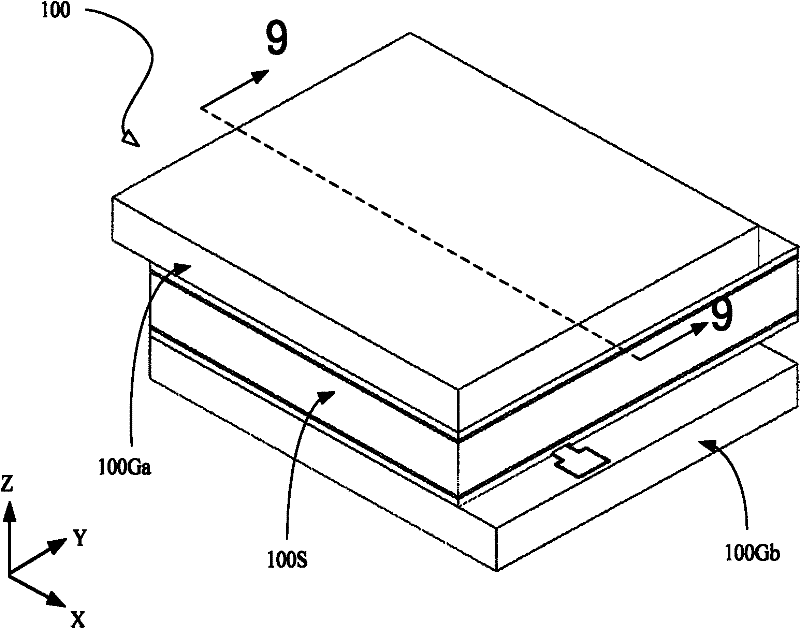

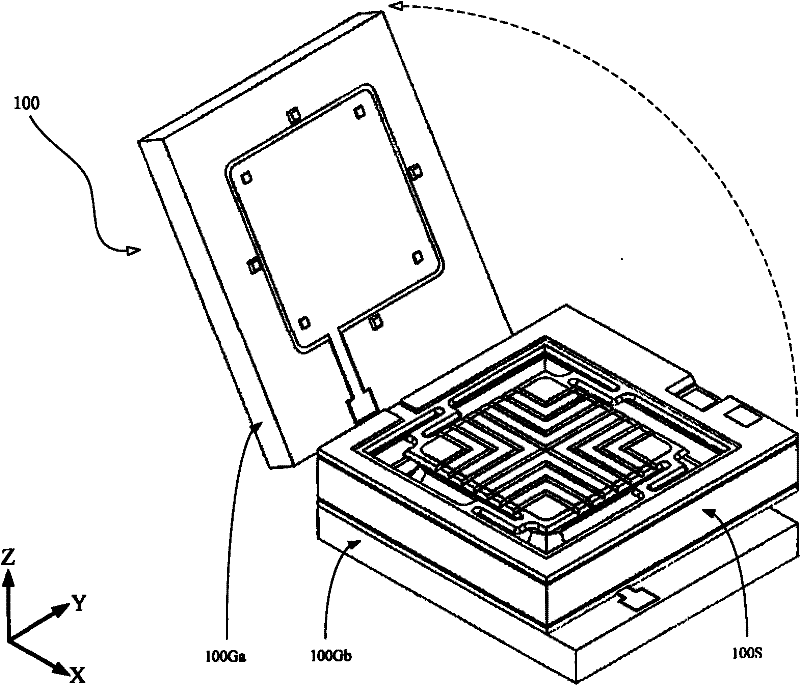

[0039] As shown in Figure 1-9, a micromachined differential capacitive accelerometer with a symmetrical structure (glass electrode cover plan). Figure 1A It is an isometric side view of a micromachine differential capacitive accelerometer (glass electrode cover plan) according to the present invention. The accelerometer 100 of the glass electrode cover plan has a glass upper electrode cover 100Ga and a glass lower electrode cover 100Gb , a silicon structural component 100S, Figure 1B It is the isometric side view of the 100 accelerometer with the upper glass electrode cover lifted.

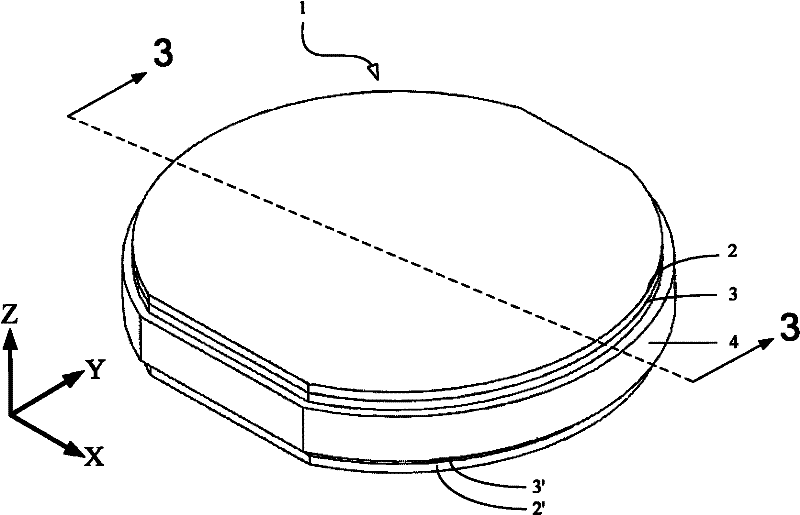

[0040] figure 2 It is the substrate 1 for processing the silicon structural component 100S, that is, the front isometric view of a double device layer SOI single crystal silicon wafer as described above, as shown in figure 2 As shown, this kind of SOI sheet has a monocrystalline silicon substrate 4, and the front and back surfaces of the monocrystalline silicon substrate 4 have silicon dioxide ...

Embodiment 2

[0050] As shown in Figure 10-12, a micromachined differential capacitive accelerometer with a symmetrical structure (single crystal silicon electrode cover plate scheme). The single crystal silicon cover plate scheme described in this example uses the same single crystal silicon structural component 100S as the glass electrode cover plate scheme described in Example 1, except that single crystal silicon is used as the electrode cover plate material, and the structure is the same as that of Electrode covers made of glass material are different. Figure 10A Shown is the front isometric view of the monocrystalline silicon upper electrode cover plate 200Ga of the micromachined differential capacitive accelerometer (single crystal silicon electrode cover plate solution) 200 according to the present invention, Figure 10B It is an isometric side view of the back side of the monocrystalline silicon upper electrode cover plate 200Ga. Since the monocrystalline silicon lower cover plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com