Central transmission mud scraper of large-sized flexible rake lift

A center-driven mud scraping and large-scale technology, applied in water/sludge/sewage treatment, sedimentation separation, water/sewage treatment, etc., can solve the problems of easy damage of mud scraping mechanism, slow rake lifting action, complex rake lifting mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

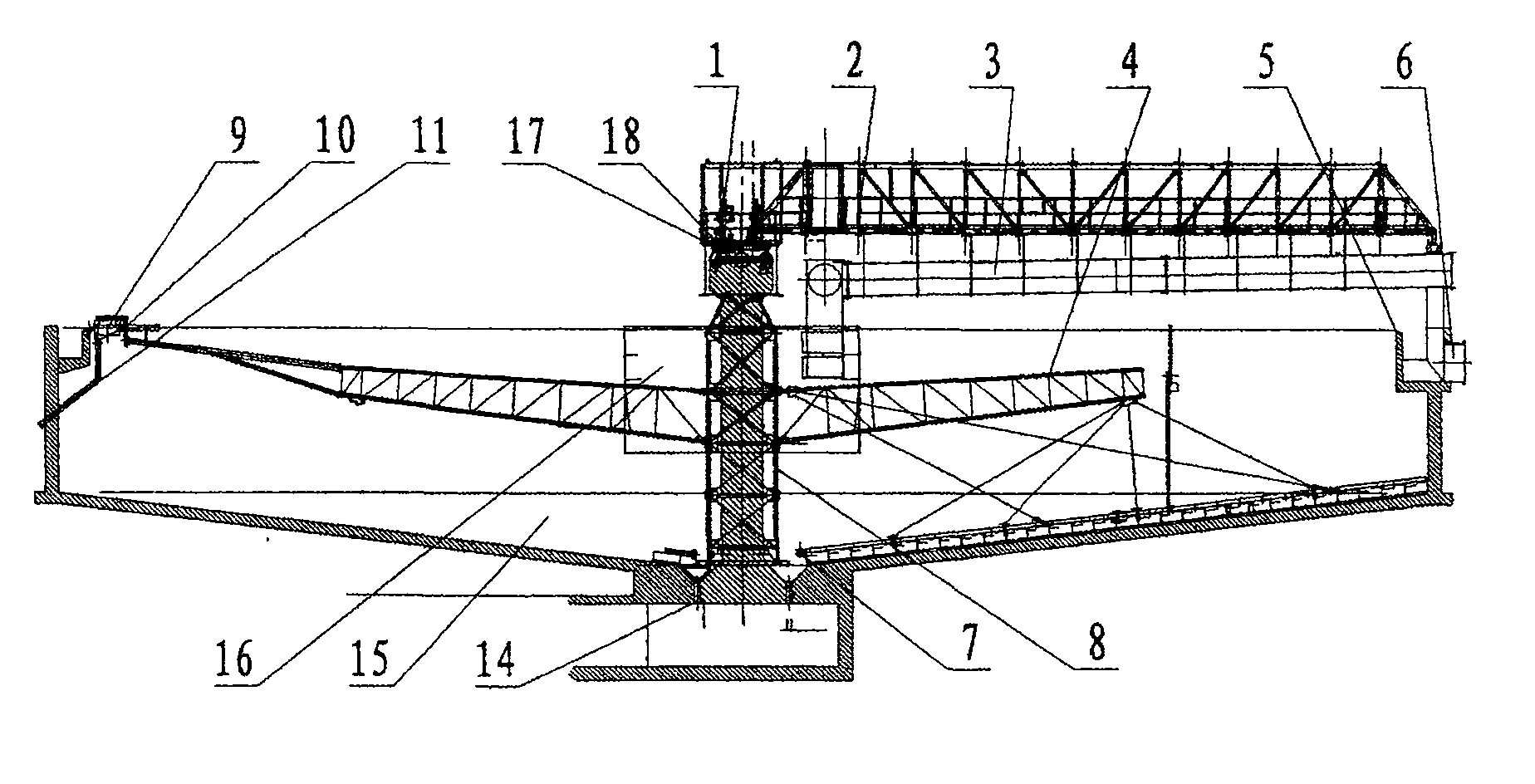

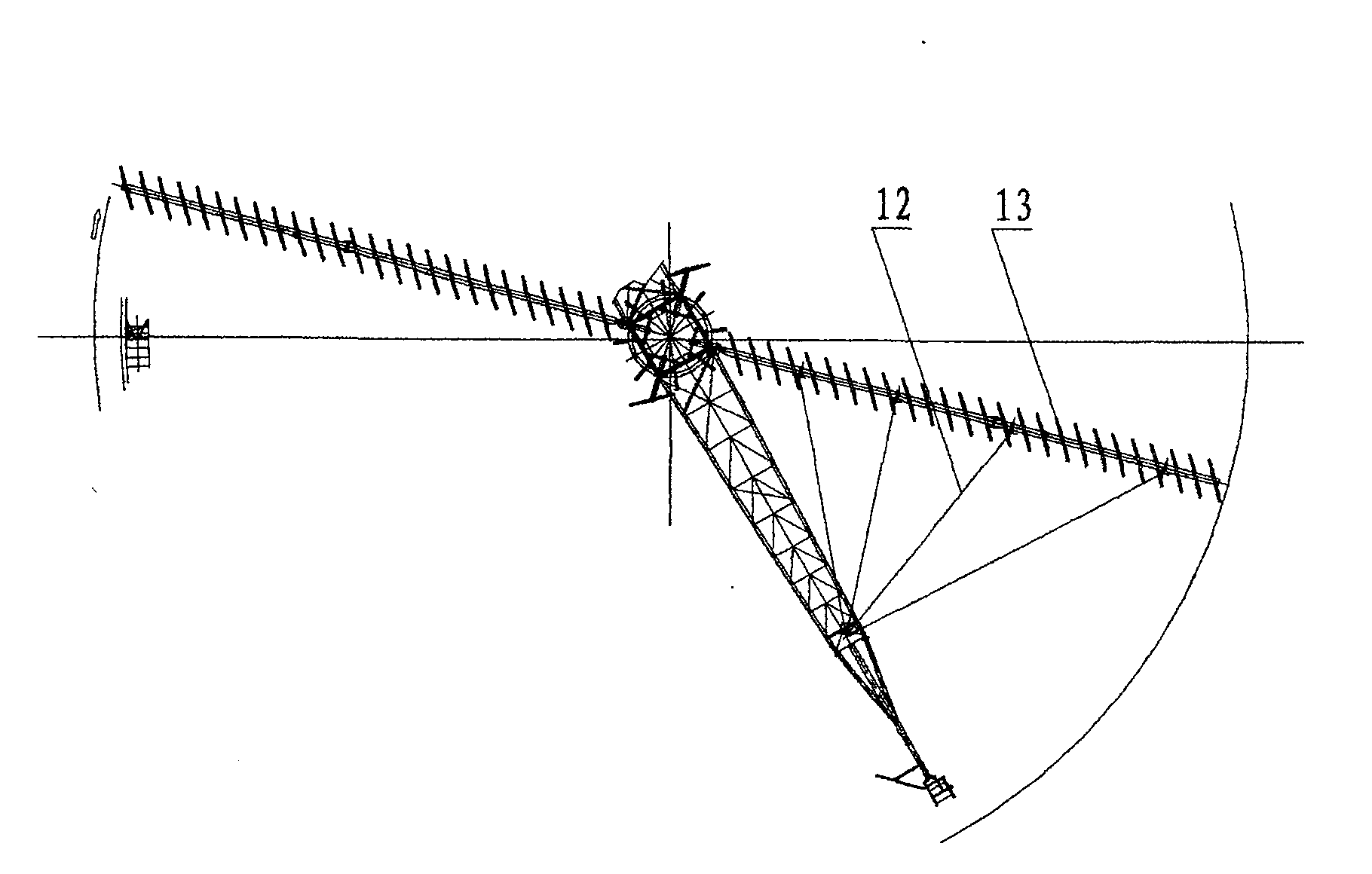

[0010] The specific details and working conditions of the present invention will be described below in conjunction with the accompanying drawings of the description.

[0011] The working conditions of the large-scale flexible lifting rake central drive mud scraper of the present invention are as follows: the ore pulp or sewage enters the radial flow sedimentation tank 15 after being stabilized by the feeding steady flow tube 16 from the water inlet pipe 3 suspended under the truss 2, and has a pass through The output shaft of 2-4 cycloidal planetary gear drive device 1 with torque protection and torque display function is equipped with a pinion 18, the external teeth of the pinion 18 mesh with the internal teeth of the slewing support 17 and drive the slewing support 17 to rotate, driving the rigid The central rotating cage 8 connected to the slewing support 17, the rotating torque arm 4, and the mud scraping rake 13 make the rotating torque arm 4 and the mud scraping rake 13 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com