Coating material for platinum material, platinum material coated with such coating material, and glass manufacturing apparatus

A coating and glass technology, applied in glass manufacturing equipment, metal material coating process, manufacturing tools, etc., can solve the problem of not being able to fully reduce air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4 and comparative example 1

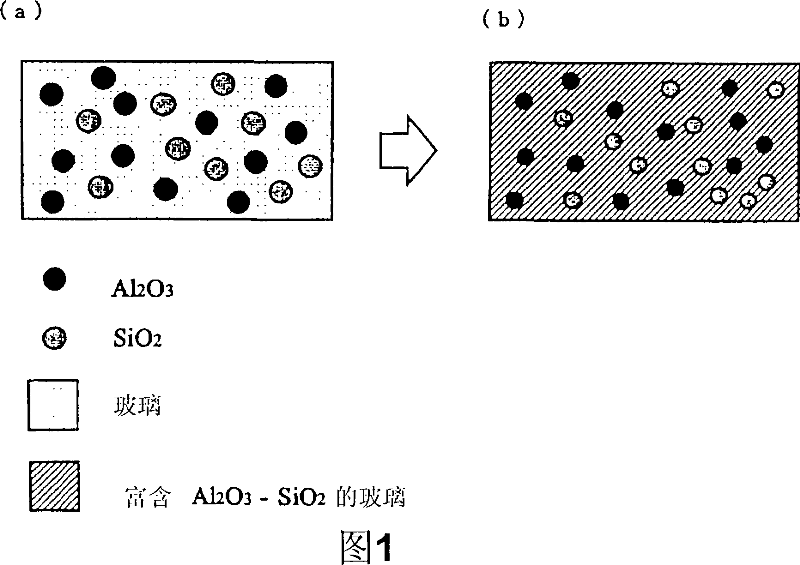

[0074] This example is an example using the coating material in the form of a slurry according to the first embodiment of the present invention.

[0075] Among them, a coating material (fired coating) is produced on a platinum alloy substrate. The coating material uses a glass component as a matrix phase and aluminum oxide and silica as a dispersed phase and disperses it. No volatile loss of platinum. In this embodiment, four types of coating materials having different contents of each component are produced. First, a raw material gel (slurry) corresponding to the composition of the prepared coating material is produced.

[0076] Alumina and silica used for the raw material gel (slurry) are those in the state of an ion-free colloidal solution (alkali-free) (colloidal silica). The alumina and silica as the dispersed phase are preferably at least one of the alumina and silica from a colloidal solution as described in this embodiment. On the other hand, as the glass component,...

Embodiment 5

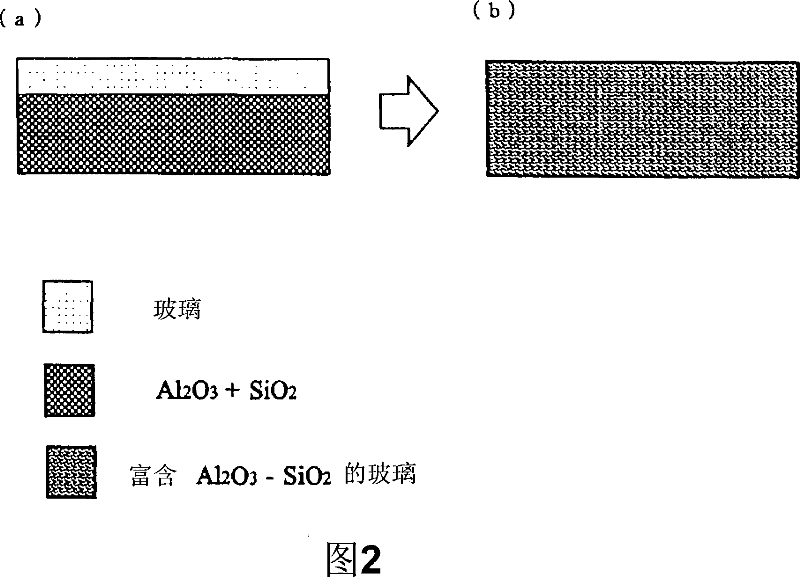

[0082] This example is an example according to the fourth embodiment of the present invention.

[0083] Among them, a coating material with a double-layer structure (fired coating) is produced. First, as a first covering layer, a raw material gel (slurry) containing alumina and silica (alumina: 53.1% by weight, silica: 46.9% by weight) was coated on a substrate. The solvent and adjustment method of this raw material gel are the same as in Examples 1-4, and only the compounding quantity was adjusted. On the other hand, the coating method is the same as in Examples 1 to 4, and is carried out by spraying. Then, after applying the gel, it was dried and fired to form a first covering layer (thickness: 150 μm).

[0084] After forming the first covering layer, a second covering layer is formed thereon. The second coating layer is a glass component layer containing 50% by weight of each of OA-10 and EF (both manufactured by NEC Glass Co., Ltd.) as glass components. The formation p...

Embodiment 6 and comparative example 2~4

[0089] This example is an example according to the first embodiment of the present invention.

[0090] Modulation has the glass composition Al shown in Table 3 2 o 3 , SiO 2 and ZrO 2 Composition of slurry. OA-10 (average particle size: 7 μm) is used as the glass component, and alumina particles (average particle size: 50 μm) are used as Al 2 o 3 , using colloidal silica (colloidal solution of silica, average particle size 20nm) as SiO 2 , using zirconia particles (average particle size 6μm) as ZrO 2 . The suspension was suspended in water twice the weight of the solid, and 3% by weight of methylcellulose was added to the weight of the solid to prepare a slurry.

[0091] [Coating slurry on platinum crucible]

[0092] After heating the inner surface of the blasted platinum crucible (diameter 46 mm, height 40 mm) with a heat gun, the slurry was sprayed on the bottom surface and the outer side of the platinum crucible for coating. The sides are coated to a height of 25 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com