Deoxidation method of al-nb-ti alloy

An al-nb-ti alloy technology, applied in the field of deoxidation of Al-Nb-Ti alloys, can solve the problems of increased manufacturing cost and time, unable to completely eliminate residual Ca, and deoxidation methods that are not described or implied, and achieve low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

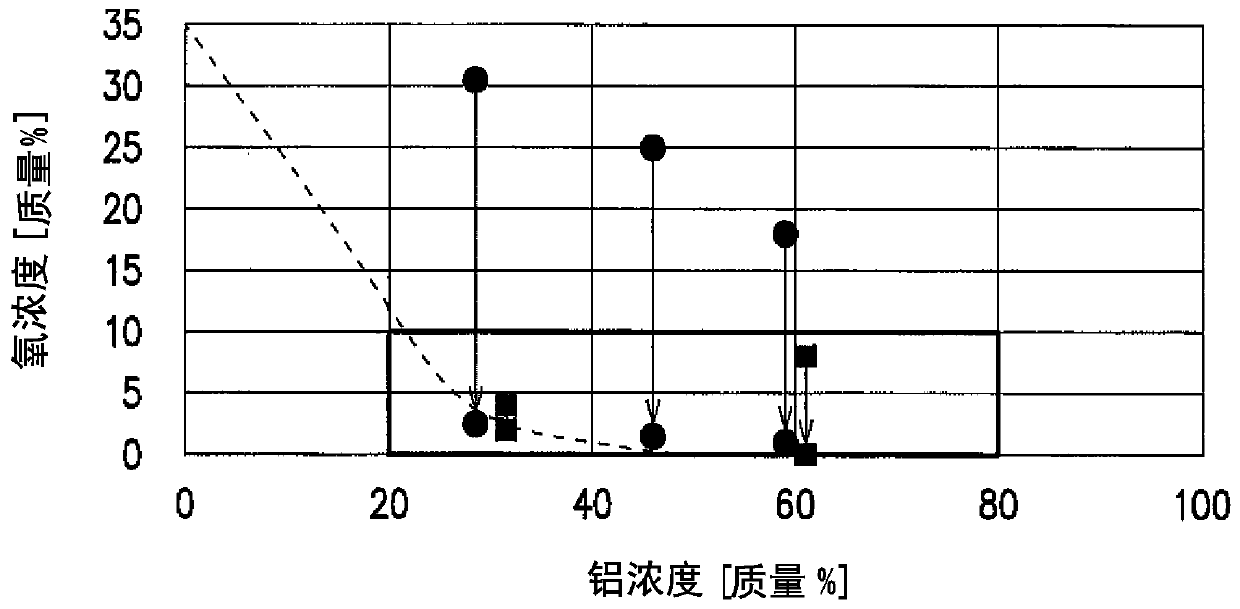

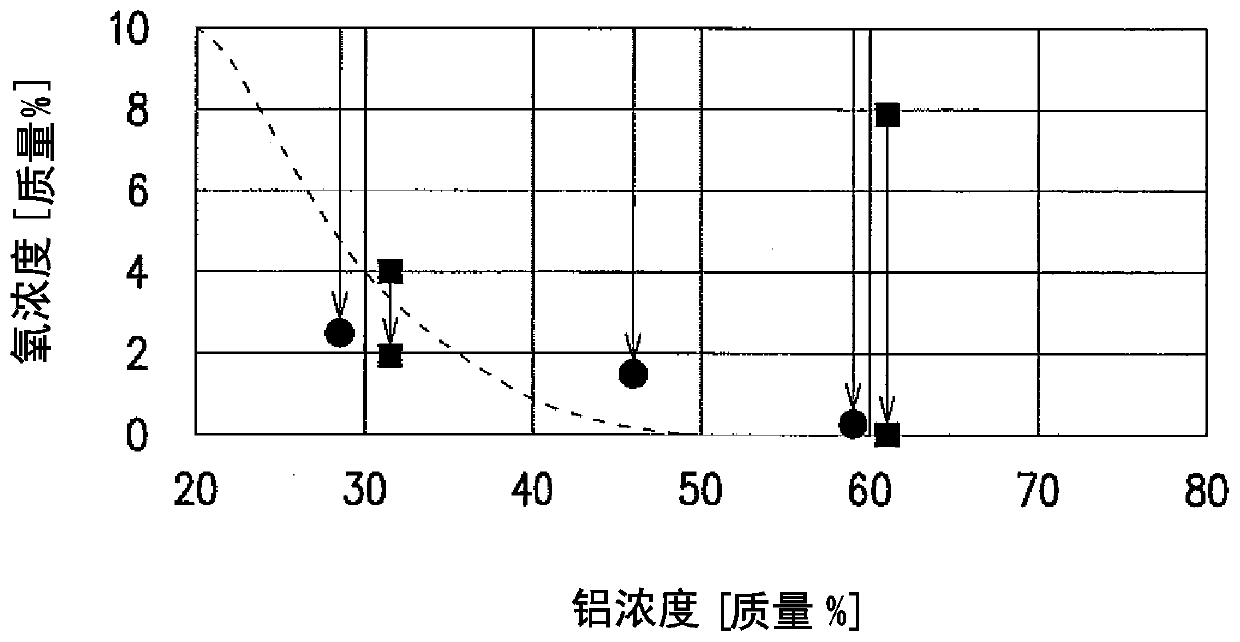

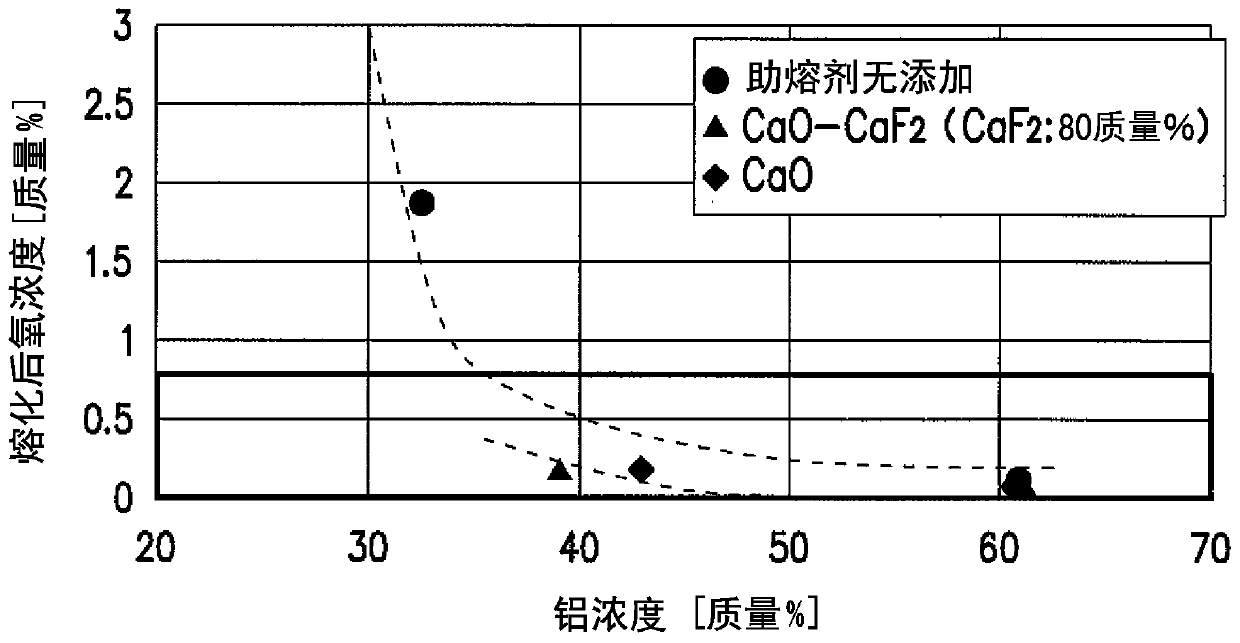

[0023] In order to use the low-quality niobium material with high oxygen content, the inventors obtained a Ti-Al-Nb alloy (Ti-Al-Nb based on active metal titanium) with a targeted composition and low oxygen content. Alloys), and conducted intensive research.

[0024] As a result, the following idea was achieved. While controlling to the desired composition, that is, the alloy composition with titanium as the main component, while reducing the oxygen content, it is technically and costly difficult. On the other hand, if the process is divided, the production of oxygen After the Al-Nb-Ti alloy with low content and aluminum as the main component, the Al-Nb-Ti alloy with low oxygen content is mixed with pure Ti with low oxygen content obtained by the usual manufacturing method. Is it possible? A Ti-Al-Nb-based alloy mainly composed of titanium of a desired composition can be obtained easily and at low cost.

[0025] Therefore, the present inventors found that the oxygen concentration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com