Environmental-protection organic silicon-modified polyether building sealant

A sealant and silicone technology, applied in the direction of polyether adhesives, adhesives, adhesive types, etc., can solve the problems of sealant aging, compatibility limitations, and different chemical structures, and achieve excellent sealing, waterproof, and adhesive Good adhesion and excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0028] Prepare

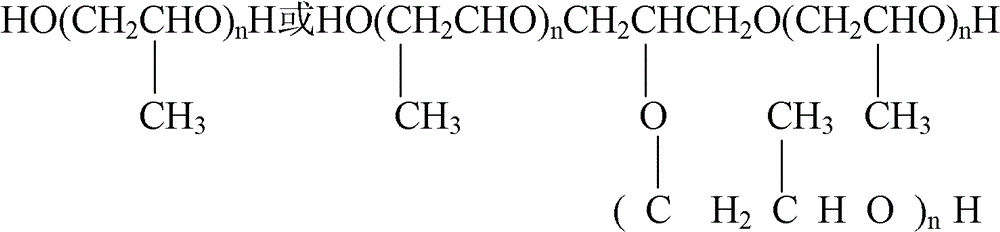

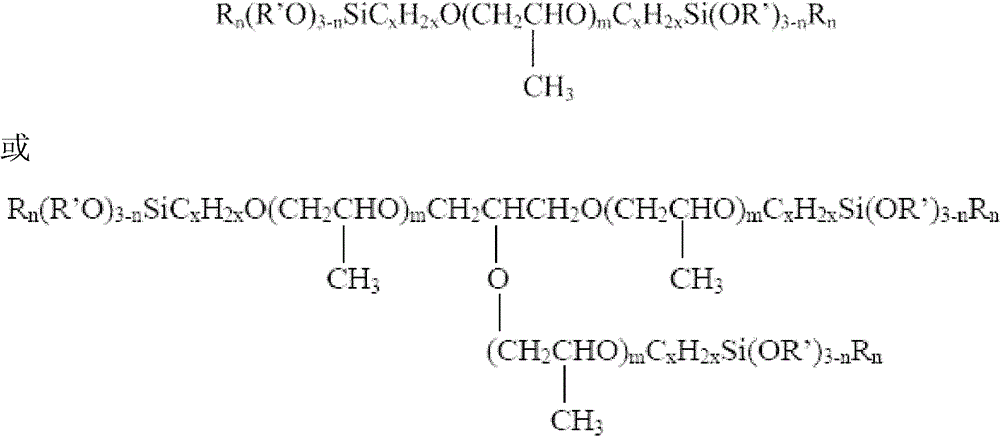

[0029] Silicone modified polyether binder

[0030] 36 kg

[0031] 15.5 kg

[0033] Vinyltrimethoxysilane 6kg

[0034] Dibutyltin dilaurate 0.5 kg

[0035] Anti-aging agent 2 kg

[0036] The above components were mixed uniformly in a planetary mixer under vacuum, and then sealed and packaged in plastic bottles to obtain sealant A. The performance test results are shown in Table 1.

preparation Embodiment 2

[0038] Prepare

[0039] Silicone modified polyether binder

[0040] 30 kg

[0041] 28 kg

[0043] Titanium dioxide 10 kg

[0044] Mercaptopropyltrimethoxysilane 8kg

[0045] Dioctyltin dilaurate 2kg

[0046] Anti-aging agent 2 kg

[0047] The above components were mixed evenly in a planetary mixer under vacuum, and then sealed and packaged in plastic bottles to obtain sealant B. The performance test results are shown in Table 1.

preparation Embodiment 3

[0049] Prepare

[0050] Silicone modified polyether binder 1

[0051] 18 kg

[0052] Silicone modified polyether binder 2

[0053] 30 kg

[0054] 30 kg

[0055] Silica 12 kg

[0056] Aminoethylaminopropyltrimethoxysilane 8 kg

[0057] 1.5kg dibutyltin dipivalate

[0058] Anti-aging agent 0.5 kg

[0059] The above components were uniformly mixed in a planetary mixer under vacuum, and then sealed and packaged in plastic bottles to obtain sealant C. The performance test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com