Cathode slurry composition for secondary battery, cathode for secondary battery produced by using same and secondary battery

A positive electrode slurry and secondary battery technology, which is applied in the direction of secondary batteries, electrode manufacturing, battery electrodes, etc., can solve the problems of insufficient electrochemical properties, deterioration of high temperature characteristics, and decreased battery adhesion, and achieve the best electrochemical properties Effects of minimized deterioration, sufficient dispersibility, and excellent high-temperature storage properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

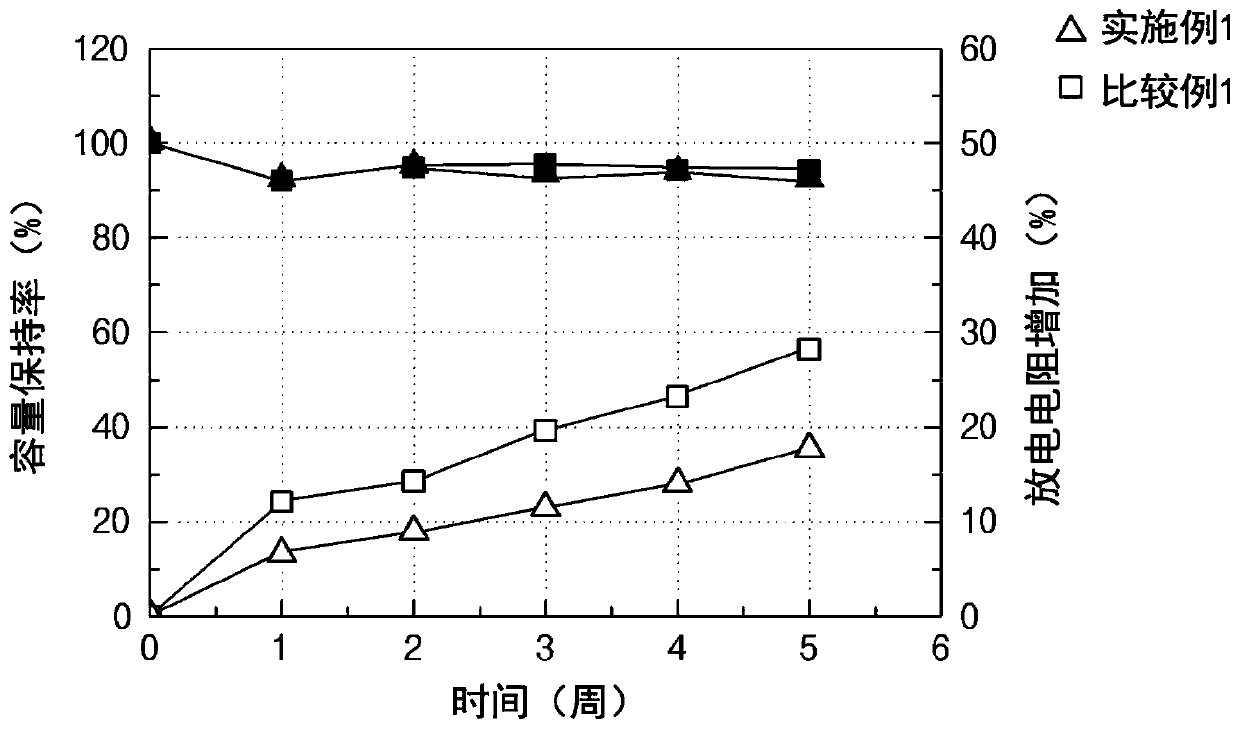

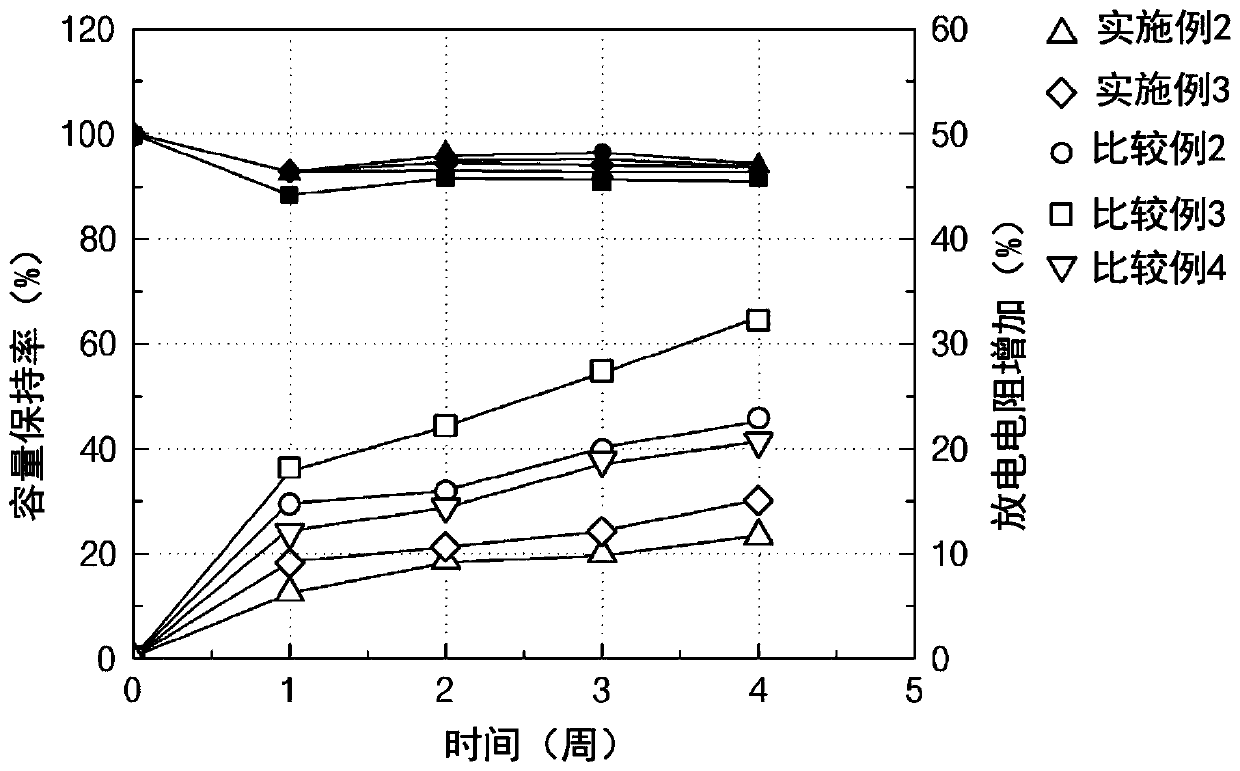

preparation example 1

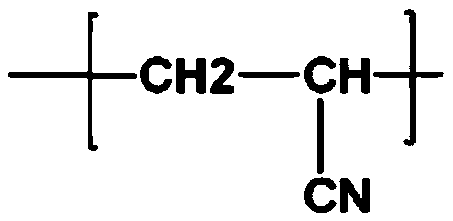

[0121] Acrylonitrile and hydrogenated butadiene are polymerized with a weight ratio of 34:66 of 0.2 parts by weight of nitrile-based copolymer (weight average molecular weight: 220,000g / mol), 2 parts by weight of carbon black (specific surface area: 135m 2 / g), 2 parts by weight of PVdF and 95.8 parts by weight of Li[Ni 0.6 co 0.2 mn 0.2 ]O 2 The positive electrode active materials were mixed, and using N-methylpyrrolidone (NMP) solvent, a positive electrode slurry composition A having a solid content of 72% by weight was prepared.

preparation example 2

[0123] Acrylonitrile and hydrogenated butadiene are polymerized with a weight ratio of 34:66 of 0.08 parts by weight of nitrile-based copolymer (weight average molecular weight: 220,000g / mol), 0.4 parts by weight of carbon nanotubes (specific surface area: 185m 2 / g), 1.5 parts by weight of PVdF and 98.02 parts by weight of Li[Ni 0.6 co 0.2 mn 0.2 ]O 2 The positive electrode active materials were mixed, and using N-methylpyrrolidone (NMP) solvent, a positive electrode slurry composition B having a solid content of 72% by weight was prepared.

preparation example 3

[0125] Acrylonitrile and hydrogenated butadiene are polymerized with 0.08 parts by weight of nitrile copolymer (weight average molecular weight: 310,000g / mol), 0.4 parts by weight of carbon nanotubes (specific surface area: 185m 2 / g), 1.5 parts by weight of PVdF and 98.02 parts by weight of Li[Ni 0.6 co 0.2 mn 0.2 ]O 2 The positive electrode active materials were mixed, and using N-methylpyrrolidone (NMP) solvent, a positive electrode slurry composition C having a solid content of 72% by weight was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com