High-temperature sapphire weighing sensor

A weighing sensor, sapphire technology, applied to the detailed information of weighing equipment, weighing equipment using elastically deformable parts, instruments, etc., can solve the problems of only being able to withstand 250°C and the sensor cannot be used, and achieve long-term Good stability, high temperature resistance, and improved temperature sensitivity accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The content of the present invention will be further described below in conjunction with the accompanying drawings, but the specific implementation forms of the present invention are not limited to the following embodiments.

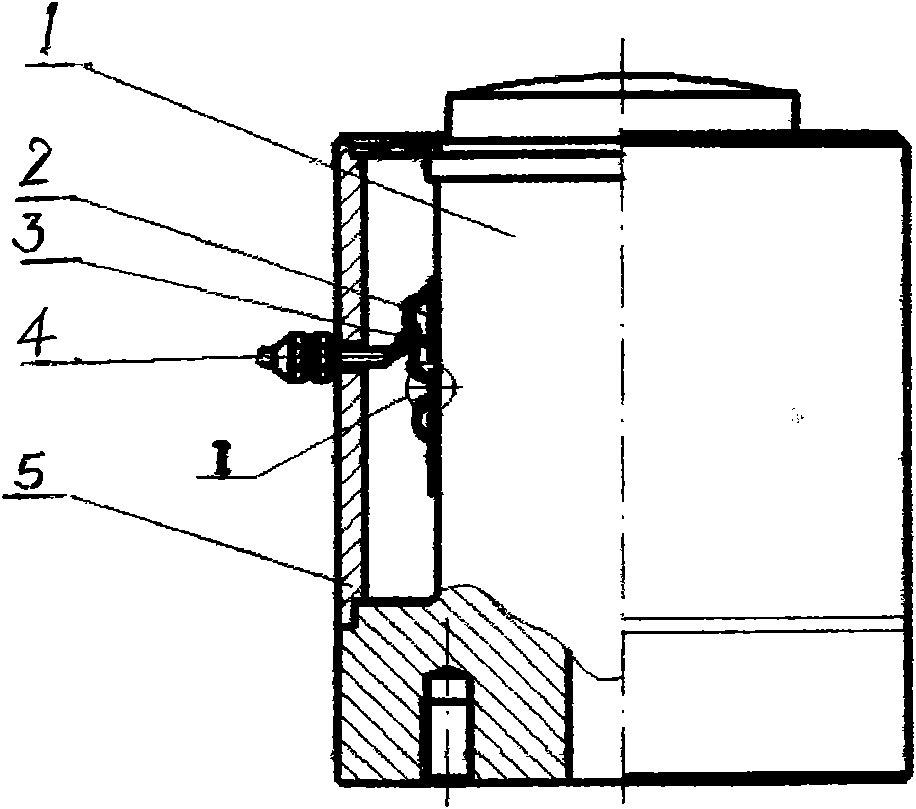

[0033] Referring to accompanying drawing, the structure of high temperature sapphire load cell of the present invention is as figure 1 As shown, it is composed of a niobium-based alloy elastic body 1, an external circuit board 2, a sensitive component 3, a cable connector 4 and a shell 5.

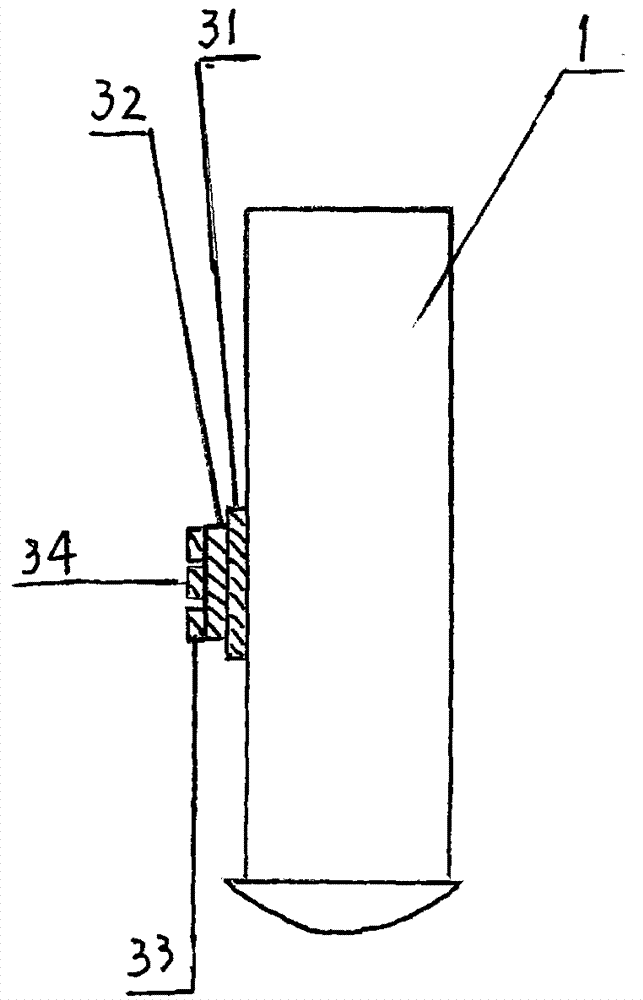

[0034] The sensitive components in this load cell are structured as figure 2 As shown, it has a sapphire substrate 31 welded on one side of the elastomer 1, and the sapphire substrate 31 is made of single crystal aluminum oxide (such as Al 2 o 3 ) with a total thickness of 40-50 μm; the sapphire substrate 31 is sequentially provided with a strain resistance layer 32 , a welding layer 33 and a passivation protection layer 34 from the inside to the outside. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com