High-speed DFB laser and manufacturing method thereof

A DFB laser, high-speed technology, applied in the direction of lasers, laser components, semiconductor lasers, etc., can solve the problems of DFB laser bandwidth limitation, reduce device heat dissipation characteristics, reduce chip heat dissipation area, etc., to achieve good lattice matching and modulation rate Fast, quality-enhancing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

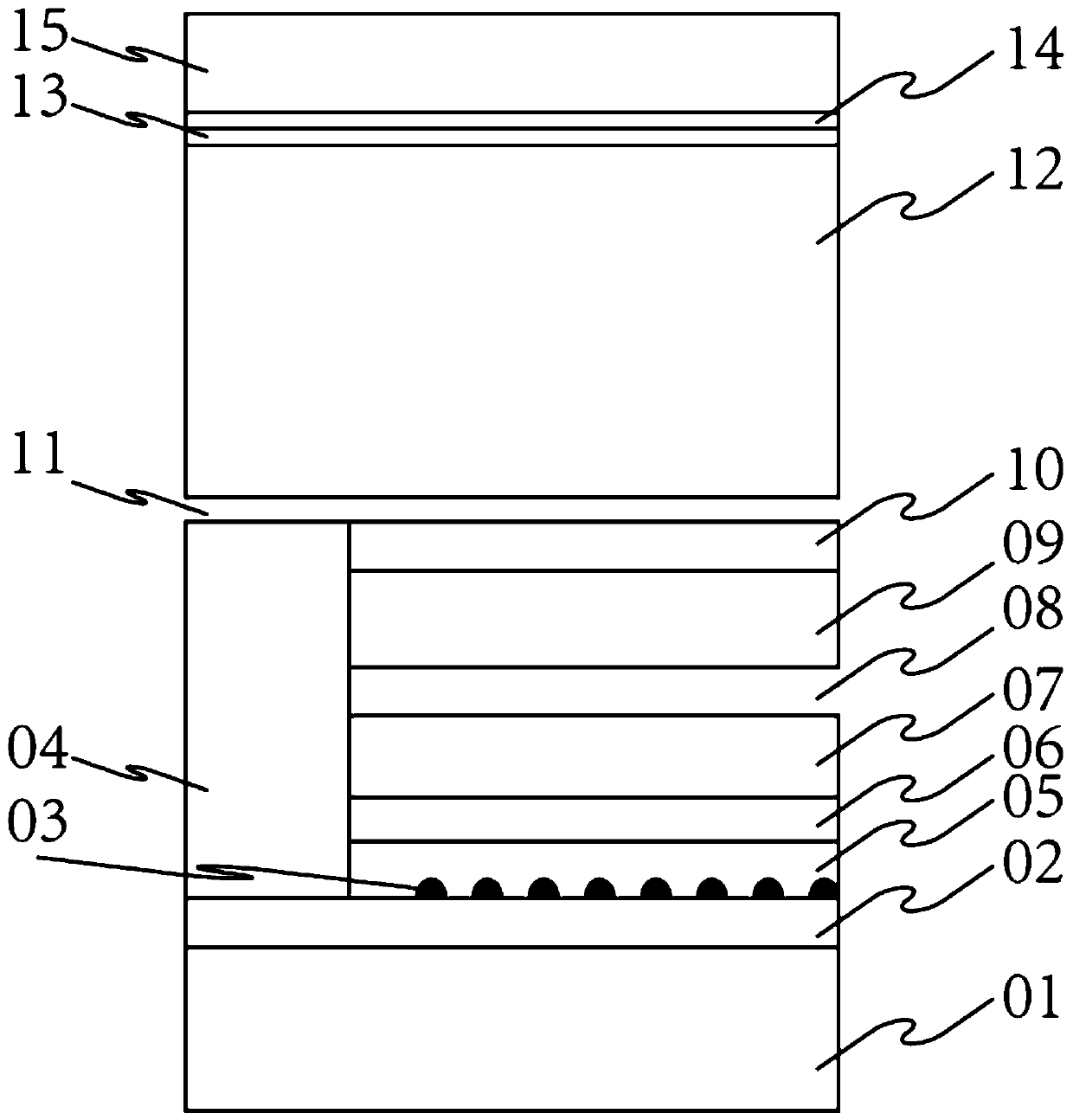

[0030] A preparation method for a high-speed DFB laser, comprising the steps of:

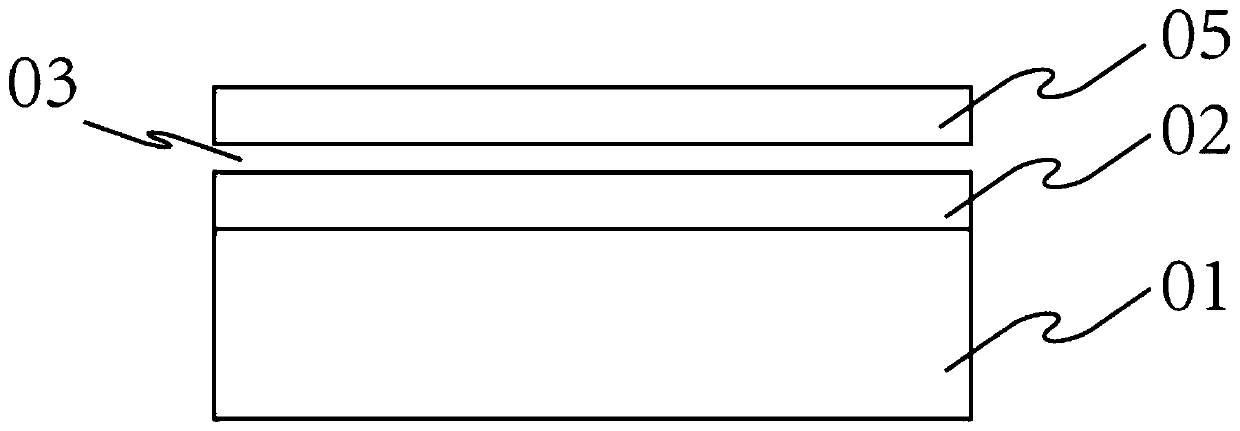

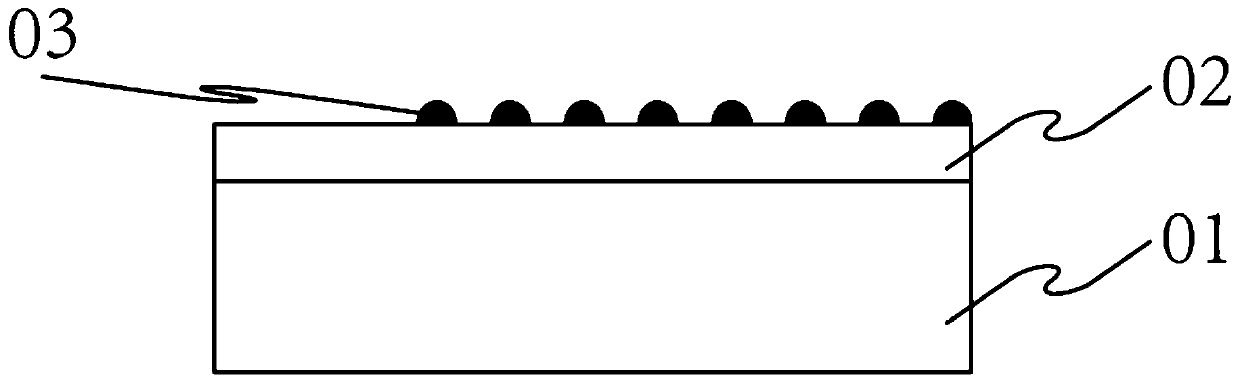

[0031] Step 1: Using InP as the growth substrate, the buffer layer 02 and the grating layer are sequentially grown on the InP substrate 01 to obtain the first epitaxial structure, such as figure 2Then take out the epitaxial wafer, spin-coat photoresist, use holographic lithography or electron beam lithography to form a grating pattern, and then use optical lithography to define the first waveguide region, and use chemical wet etching method to form a partial raster; as in image 3 shown.

[0032] Step 2: Carry out the second epitaxial growth on the basis of step 1; first, in the pH 3 Under the protection of gas, slowly raise the temperature to 550°C, and then feed TMIn in pulses as the source gas to grow InP. When the thickness of the InP layer 050 completely covers the grating, raise the temperature to the normal epitaxial growth temperature of 670°C, increase the flow rate of TMIn, from Ra...

specific Embodiment

[0040] With a conductivity of 2-8x10 18 cm -2 The InP is used as the growth substrate and put into the MOCVD system of Aixtron Company for growth. The reaction chamber pressure was 50mbar, the growth temperature was 670°C, and the 2 As carrier gas, trimethylindium (TMIn), trimethylgallium (TMGa), trimethylaluminum (TMAl), diethylzinc (DeZn), silane (SiH 4 ), arsine (AsH 3 ) and phosphine (PH 3 ) and the like are reaction source gases, and sequentially grow an N-InP buffer layer, an N-InGaAsP grating layer, and an N-InP transition layer. Among them, the thickness of the grating layer is 50nm. It is worth noting that the grating layer N-InGaAsP is a tensile strain, and the strain is 500-1000ppm.

[0041] Then the grown epitaxial wafer is taken out, and a grating is formed by holographic lithography or electron beam lithography. The grating period is 203nm and the depth is 70nm. At the same time, the wave layer region B is formed by optical lithography, and the width of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com