Guide self-locking bolt connecting assembly for blind hole and use method

A connecting component and guiding technology, applied in the direction of connecting components, bolts, threaded fasteners, etc., can solve the problems of unsatisfactory safety and reliability, high maintenance cost, low flight safety factor of aerospace vehicles, etc. Easy to manufacture, simple and reasonable in structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further understand the content, features, and effects of the present invention, the following examples are given to illustrate in detail as follows:

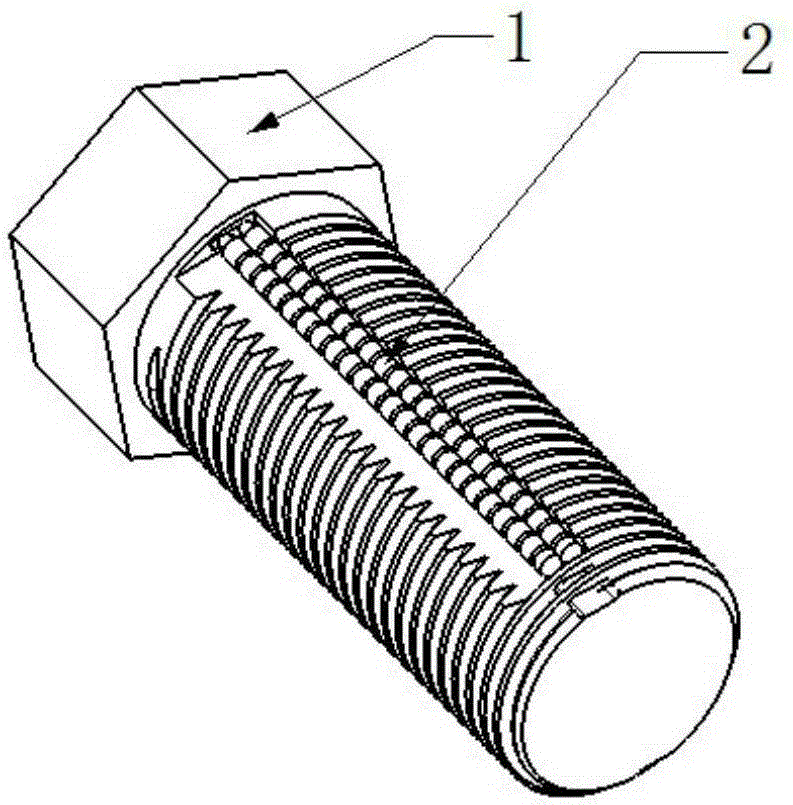

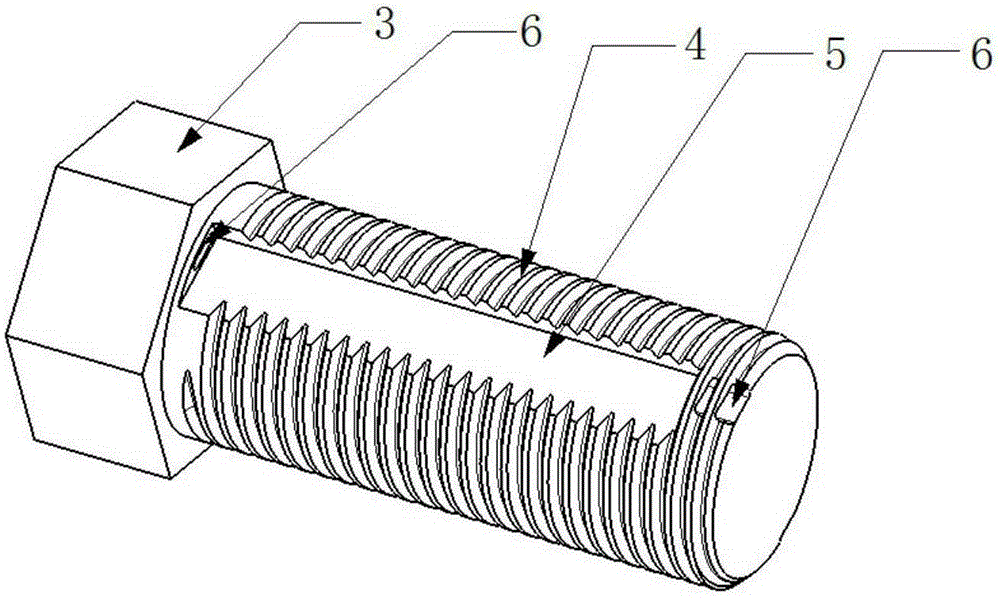

[0018] See figure 1 with figure 2 The present invention includes a self-locking bolt 1 composed of a head 3 and a threaded rod 4. At least one angular groove 5 extending in the axial direction is provided on the outer wall of the threaded rod 4.

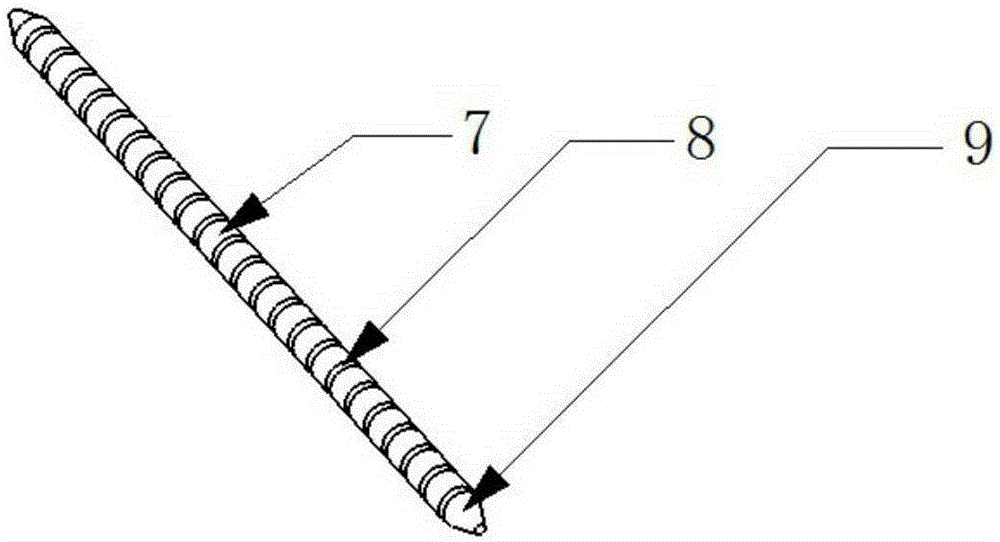

[0019] Two guide pins 2 side by side are arranged in each corner groove 5. Such as image 3 As shown in the figure, the guide pin 2 includes a straight cylindrical guide pin body 7. A plurality of annular thread grooves 8 are provided on the outer wall of the guide pin body 7, and the distance between two adjacent annular thread grooves 8 is equal to the threaded rod 4 The pitch of the upper thread. Mounting ends 9 are provided at both ends of the guide pin body 7, and the depth of the angle groove 5 is greater than or equal to the diameter of the guide pin body 7.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com