High-reliability rectification device application chip with composite inner passive film single-groove structure

A rectifier device and reliability technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as poor reliability and poor high temperature characteristics, and achieve the effect of increasing voltage, good thermal stability, and increasing breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation will be described in detail below in conjunction with the accompanying drawings:

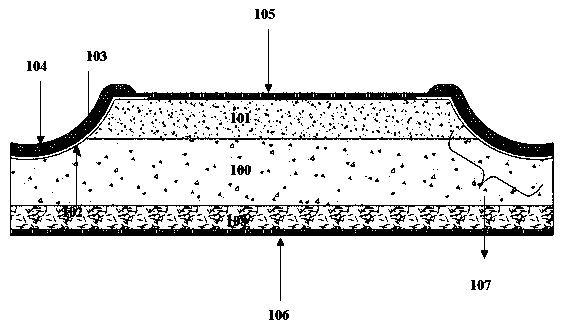

[0022] 109 figure 1 A schematic structural diagram of an embodiment of the present invention is given. In the figure, a compound internal passivation layer structure of a silicon rectifier device includes: a middle layer 100 single crystal semiconductor body, an upper layer 101 is a chip body with a P-type doped layer or an N-type doped layer, and a lower layer 108 is an N-type The chip body of the doped layer or the P-type doped layer (see 108 above for details), the mesa 107, the upper electrode metal layer 105, the lower electrode metal layer 106, the polysilicon thin film in the mesa structure region and the nanoscale high-purity oxidation layer underneath it. Layer 102, silicon nitride film 103 in the mesa structure area, glass passivation layer 104 made of special glass material; the polysilicon film in the mesa structure area and the nanoscale high-puri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com