Susceptor

A susceptor and substrate technology, applied in the field of susceptors, can solve the problems that it is difficult to obtain multiple epitaxial films with the same quality at the same time, the temperature difference of the substrate, and the thickness of the epitaxial film are different.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

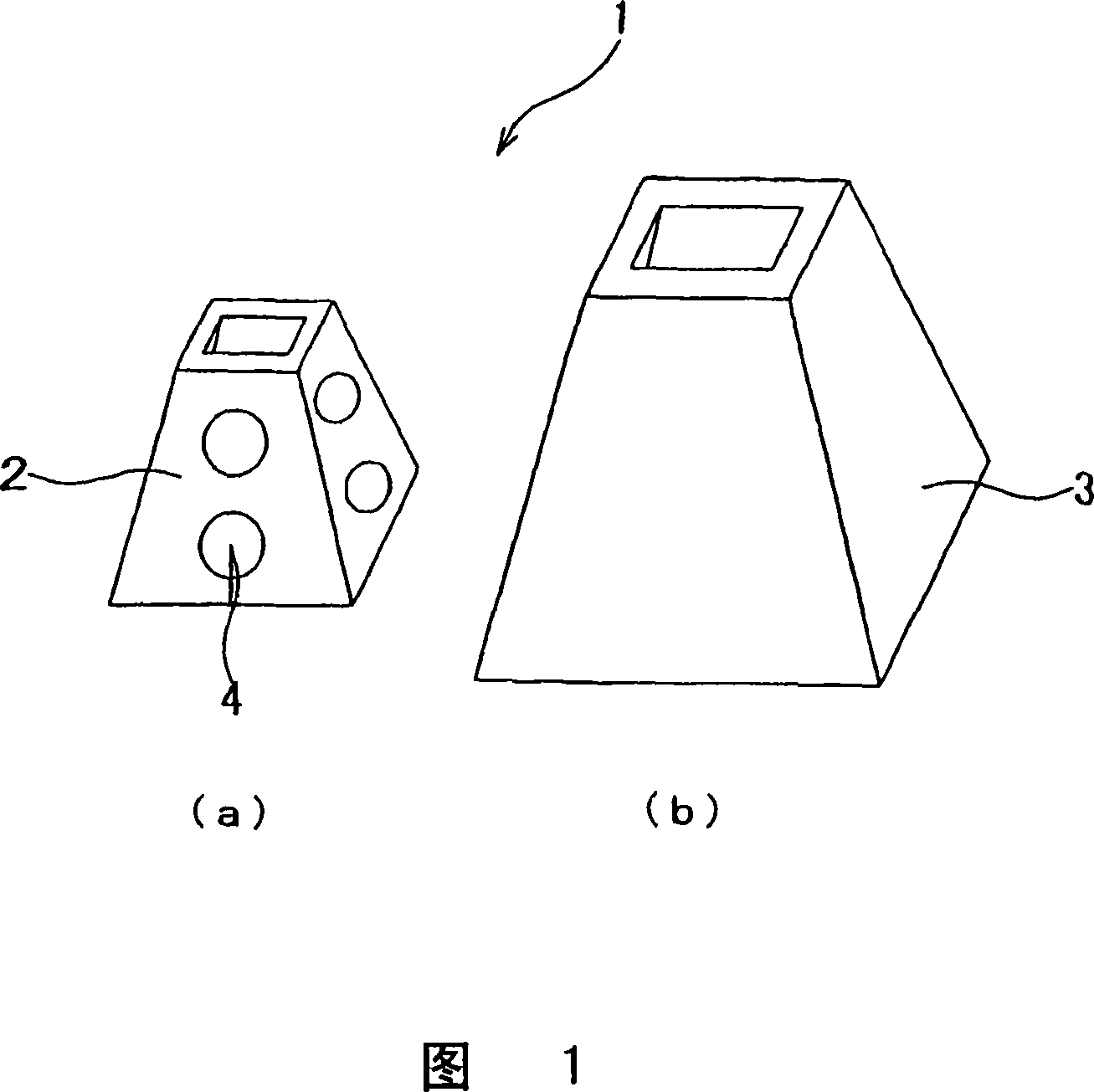

[0065] Here is shown an example of forming an epitaxial layer using a cylindrical gas phase reactor using a six-sided cylindrical susceptor (not shown) instead of the four-sided cylindrical susceptor 1 in FIG. 1 . Here, the epitaxial layer formation of silicon carbide, which is one of compound semiconductors, will be described.

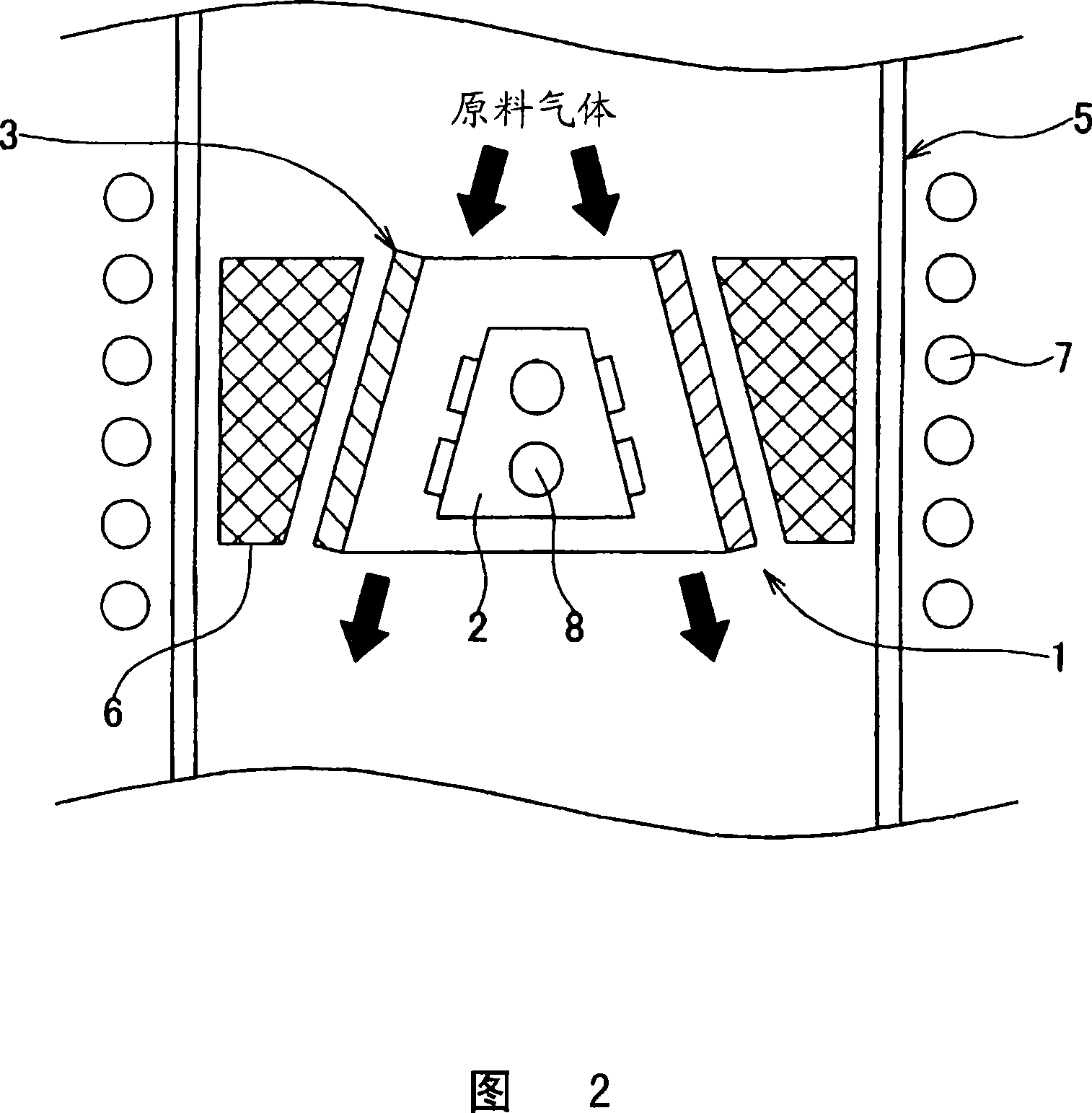

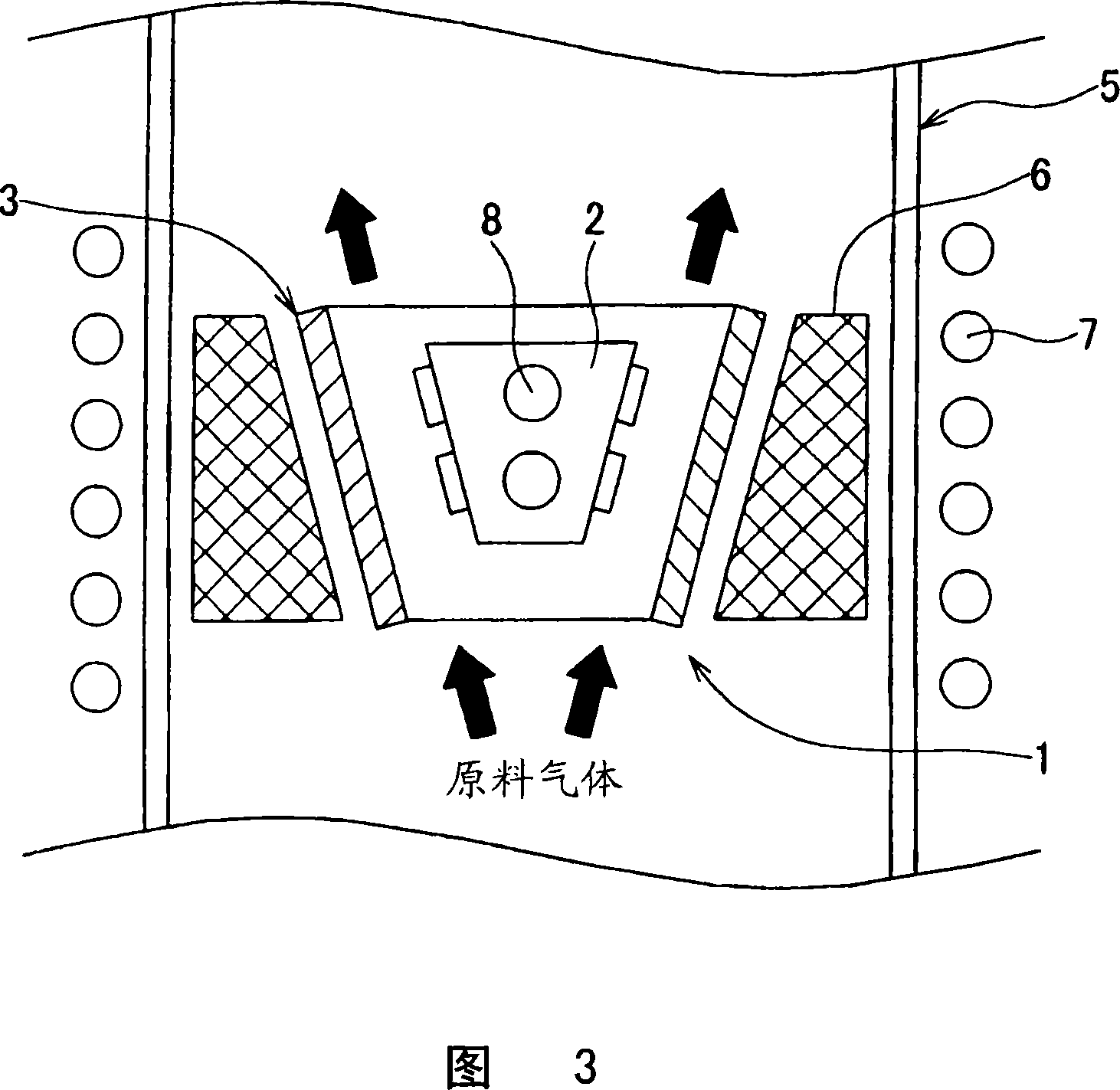

[0066] Single-crystal silicon carbide wafers each having a diameter of 2 inches were placed in each counterbore provided on the inner surface of the six-sided cylindrical susceptor, and the susceptor was set at a predetermined position. with H 2 After the gas replaces the gas in the reaction chamber, it is pumped into 5×10 -6 Torr's Vacuum. After evacuation, introduce H as a carrier gas from a source gas supply port (not shown). 2 As an inert gas, Ar gas was introduced from an inert gas supply port (not shown), and the reaction chamber was maintained at 100 Torr. h 2 Ar gas and Ar gas are continuously discharged from an exhaust port (not shown), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com